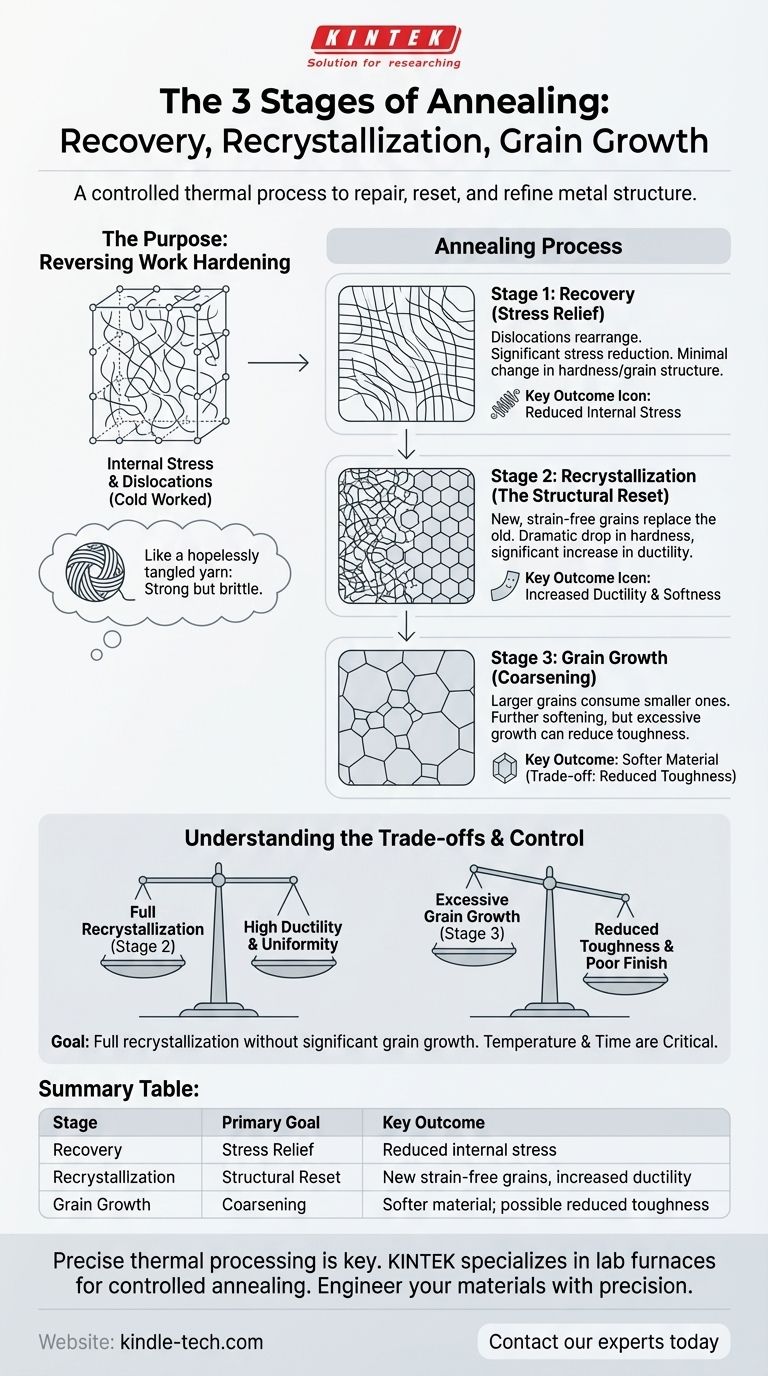

The three stages of annealing are Recovery, Recrystallization, and Grain Growth. These distinct phases occur sequentially as a metal is heated, systematically repairing and resetting its internal crystal structure to reverse the effects of strain and restore its workability.

Annealing is not a single event but a controlled, three-stage process that first repairs, then replaces, and finally refines a metal's internal structure. Understanding these stages is key to precisely controlling a material's final properties, like its ductility and hardness.

The Purpose of Annealing: Reversing Work Hardening

The Problem of Internal Stress

When a metal is bent, stretched, or shaped at room temperature—a process called cold working—it becomes harder and stronger. This happens because its internal crystal structure becomes filled with defects and tangled lines of atomic mismatch, known as dislocations.

Think of this stressed state like a hopelessly tangled ball of yarn. The more you work it, the tighter the knots become. The material is strong, but it's also brittle and resists any further attempts to shape it.

The Goal of Annealing

Annealing is the thermal treatment used to methodically untangle that internal structure. By applying heat, we give the atoms in the crystal lattice the energy they need to rearrange themselves into a more orderly, lower-stress state, making the material workable again.

A Microscopic Look at the Three Stages

As the temperature of the cold-worked metal rises, it passes through three distinct and transformative stages.

Stage 1: Recovery (Stress Relief)

At relatively low temperatures, the first stage of healing begins. The added thermal energy allows the tangled dislocations to move and rearrange themselves into more orderly, lower-energy patterns.

This process significantly reduces the material's internal stress. While the overall grain structure and hardness are only slightly affected, this "stress relief" is critical for preventing cracking and improving properties like electrical conductivity.

Stage 2: Recrystallization (The Structural Reset)

As the temperature increases further, a critical point is reached. Entirely new, perfectly formed, and strain-free crystals (grains) begin to nucleate within the old, deformed structure.

These new grains rapidly grow and consume the old, defect-ridden grains until the entire microstructure is replaced. This stage is the heart of the annealing process, causing a dramatic drop in hardness and a significant increase in ductility, restoring the material's softness and formability.

Stage 3: Grain Growth (Coarsening)

If the metal is held at the annealing temperature for too long or heated to an even higher temperature after recrystallization is complete, the final stage begins. The new, strain-free grains start to coarsen.

To minimize their total energy, larger grains grow by consuming their smaller neighbors. This process further softens the material but can be detrimental if not properly controlled.

Understanding the Trade-offs

Annealing is a powerful process, but achieving the desired outcome requires understanding the balance between its stages.

The Risk of Excessive Grain Growth

While recrystallization is desirable for restoring ductility, allowing grain growth to proceed unchecked can be a mistake. Overly large grains can reduce the material's toughness and lead to a poor surface finish after subsequent forming operations.

The Balance of Properties

For most applications, the goal is to achieve full recrystallization (Stage 2) without initiating significant grain growth (Stage 3). This provides the optimal balance of high ductility for forming and a fine, uniform grain structure for good final mechanical properties.

Temperature and Time are Critical

Each stage is a function of both temperature and time. A lower temperature for a longer duration can produce the same result as a higher temperature for a shorter one. Precise control of both variables is essential to stop the process exactly where needed.

Making the Right Choice for Your Goal

The stage you target during annealing depends entirely on your desired outcome for the material.

- If your primary focus is stress relief only: Target the Recovery stage with a lower-temperature anneal to reduce internal stresses without significantly softening the material.

- If your primary focus is maximum ductility and workability: Target the completion of the Recrystallization stage to create a new, soft, strain-free grain structure.

- If your primary focus is specific properties like creep resistance: Carefully control the Grain Growth stage, as a coarser grain size can be beneficial for certain high-temperature applications.

By mastering these three stages, you move from simply heating a metal to precisely engineering its internal structure and performance.

Summary Table:

| Stage | Primary Goal | Key Outcome |

|---|---|---|

| Recovery | Stress Relief | Reduced internal stress, minimal change in hardness |

| Recrystallization | Structural Reset | New, strain-free grains; significant increase in ductility |

| Grain Growth | Coarsening | Softer material; can reduce toughness if excessive |

Precise thermal processing is key to material performance. Whether your goal is stress relief, maximum ductility, or controlled grain growth, the right lab equipment ensures you hit the target. KINTEK specializes in the lab furnaces and consumables needed for controlled annealing processes.

Let us help you engineer your materials' properties with precision. Contact our experts today to discuss your specific application and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining