At its core, a tube furnace offers superior temperature uniformity and process control. Its primary advantages stem from a simple, mature design that encases a sample within a cylindrical heating chamber, ensuring highly consistent and repeatable thermal processing. This makes it a foundational tool for a wide range of scientific and industrial applications.

The fundamental benefit of a tube furnace isn't just its ability to get hot, but its capacity to create a highly controlled and uniform thermal environment. This precision is what enables reliable material synthesis, consistent heat treatment, and repeatable experimental outcomes.

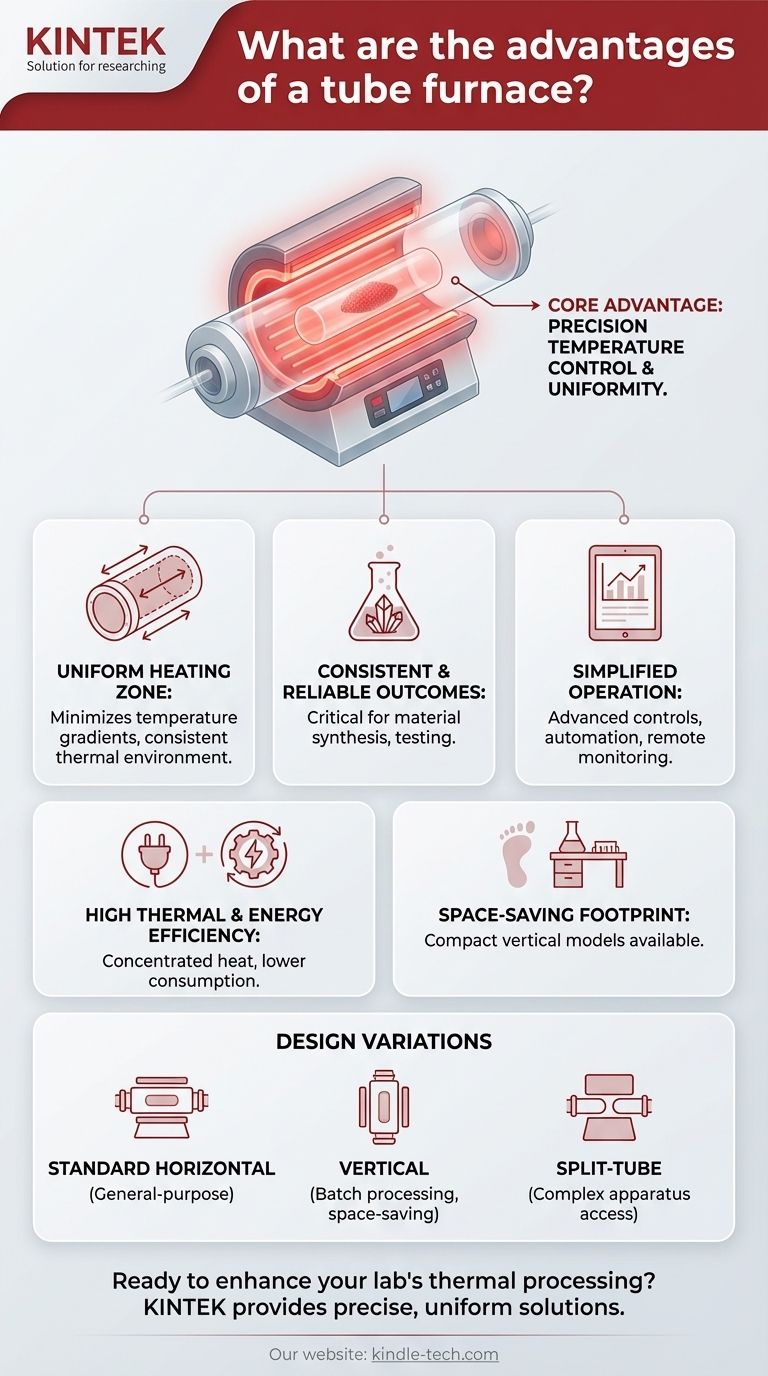

The Core Advantage: Precision Temperature Control

The most significant advantage of a tube furnace is its ability to deliver exceptionally uniform heat to a sample. The design is engineered specifically for this purpose.

Uniform Heating Zone

A tube furnace uses heating elements arranged symmetrically around a central tube. This cylindrical architecture minimizes temperature gradients, creating a stable and homogenous heating zone along the tube's length.

Consistent and Reliable Outcomes

This temperature uniformity ensures that the entire sample is processed under the same conditions. This consistency is critical for applications like crystal growth, semiconductor fabrication, and materials testing, where even minor thermal variations can lead to failed results.

Key Operational and Design Benefits

Beyond temperature control, the design of a tube furnace provides several practical advantages related to its operation, efficiency, and versatility.

Simplified Operation and Control

Most modern tube furnaces feature advanced control systems that are easy to operate. Their simple structure and mature technology allow for straightforward automation, intelligent programming, and even remote monitoring, enabling continuous and unattended production.

High Thermal and Energy Efficiency

The enclosed design concentrates heat directly on the process tube, leading to high thermal efficiency and lower power consumption. In some industrial applications, such as chemical cracking, the system allows for the recovery and reuse of heat from flue gas, further boosting efficiency.

Space-Saving Footprint

Compared to other furnace types of similar capacity, tube furnaces often have a more compact design. Vertical tube furnace models are particularly well-suited for laboratories where floor space is limited.

Understanding the Design Variations

The basic tube furnace design has been adapted for specific needs, and understanding these variations is key to choosing the right instrument.

Standard Horizontal Furnaces

This is the most common configuration, used for a vast array of general-purpose heat treatment and materials processing tasks. Samples are typically placed in ceramic or metal "boats" and pushed into the heating zone.

Vertical Furnaces

By orienting the tube vertically, these furnaces simplify the loading and unloading of samples, which is especially convenient for batch processing. This design can also be advantageous for certain material synthesis applications.

Split-Tube Furnaces

A split-tube furnace can be opened along its length like a clamshell. This is a critical feature for installing process tubes that have large flanges or complex end-fittings that would not fit through the opening of a standard, non-split furnace.

How to Apply This to Your Goal

Your choice of furnace should be dictated by the specific requirements of your process.

- If your primary focus is high-purity material synthesis or annealing: The exceptional temperature uniformity of a standard tube furnace is its most critical advantage.

- If your primary focus is convenient batch processing or you have limited lab space: A vertical tube furnace offers the best combination of accessibility and a compact footprint.

- If your primary focus is using sealed reactors or complex testing apparatus: A split-tube furnace is essential, as it is the only design that accommodates process tubes with large end-fittings.

- If your primary focus is scalable industrial production: The ability to run continuous processes and link multiple furnaces makes this a reliable choice for large-scale manufacturing.

Ultimately, the tube furnace is an indispensable tool because it provides a reliable and precise environment for manipulating materials with heat.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Precision Temperature Control | Exceptional temperature uniformity for reliable results | Material synthesis, annealing, semiconductor fabrication |

| Versatile Design Options | Horizontal, vertical, and split-tube configurations | Batch processing, limited space, complex apparatus |

| High Thermal Efficiency | Concentrated heating and potential for heat recovery | Energy-conscious labs, industrial production |

| Simplified Operation | Advanced control systems for automation and monitoring | Continuous processes, unattended operation |

Ready to enhance your lab's thermal processing capabilities?

A tube furnace from KINTEK provides the precise temperature control and uniform heating essential for reliable material synthesis, heat treatment, and experimental repeatability. Whether you need a standard horizontal, space-saving vertical, or convenient split-tube design, our expertise ensures you get the right solution for your specific application.

Let KINTEK, a specialist in laboratory equipment, help you achieve superior results. Contact our experts today to discuss your requirements and discover how our tube furnaces can drive efficiency and accuracy in your work.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- Why are high-temperature muffle or tube furnaces necessary for processing oxide solid electrolytes like LLZO or LATP?

- What is the core function of high-temperature carbonization at 800 °C in a tube furnace? Optimize Electrocatalysts

- Why is a tube furnace required for LiCoO2 thin film treatment? Unlock Crystalline Efficiency with Controlled Oxygen

- What is the basic construction and temperature control mechanism of a laboratory tube furnace? Master Precision Heating for Your Lab

- Why is a vacuum tube furnace required for nanocomposite synthesis? Protect Your High-Purity Materials

- What are the primary functions of a high-temperature tube furnace? Master EP-823 Steel Heat Treatment

- What are the technical advantages of using a tube furnace? Optimize Heat Treatment for New Metallic Alloys

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation