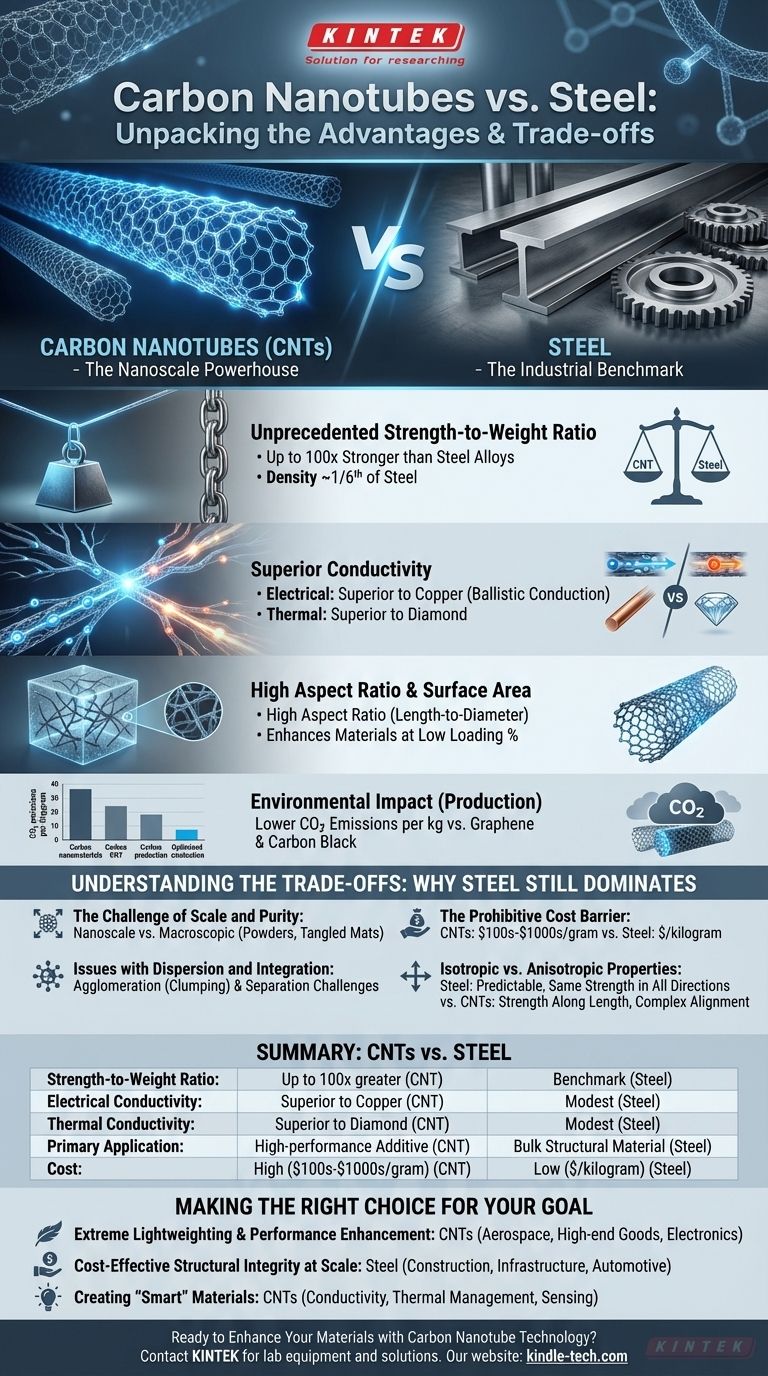

On a microscopic level, carbon nanotubes (CNTs) possess properties that make them one of the strongest and most conductive materials ever discovered, far exceeding steel in specific metrics. Their primary advantages lie in an unparalleled strength-to-weight ratio and exceptional electrical and thermal conductivity.

While the theoretical properties of a single carbon nanotube are vastly superior to steel, its practical application is fundamentally different. Steel is a cost-effective, isotropic, bulk material for large-scale structures, whereas CNTs are a high-performance additive used to enhance other materials on a microscopic level.

The Core Advantages: Unpacking CNT Properties

The excitement surrounding carbon nanotubes stems from a unique combination of properties at the nanoscale. Steel is a benchmark for industrial materials, but CNTs redefine performance in several key areas.

Unprecedented Strength-to-Weight Ratio

A single carbon nanotube is extraordinarily strong, with a tensile strength estimated to be up to 100 times greater than that of the strongest steel alloys.

Simultaneously, their density is about one-sixth that of steel. This combination creates a strength-to-weight ratio that is hundreds of times better than steel, making them a focal point for aerospace and high-performance composites.

Imagine a cable made of steel and one woven from CNTs, both able to lift the same weight. The CNT cable would be dramatically thinner and lighter.

Superior Electrical and Thermal Conductivity

Steel is a modest conductor of electricity and heat. In contrast, certain types of CNTs exhibit ballistic conduction, meaning electrons can flow through them with virtually zero resistance.

This makes their electrical conductivity superior to copper, while being far more durable and lightweight.

Their structure also allows them to conduct heat exceptionally well along their length. This thermal conductivity surpasses that of diamond, making CNTs ideal for dissipating heat in microelectronics and advanced systems.

High Aspect Ratio and Surface Area

CNTs are long, thin cylinders, giving them a very high aspect ratio (length-to-diameter). This geometry is crucial when they are used as additives.

A small amount of CNTs can create a vast interlocking conductive and reinforcing network within another material, like a polymer or epoxy. This dramatically enhances the host material's strength and conductivity at very low loading percentages.

A Note on Environmental Impact

When evaluating advanced materials, the production footprint is a critical factor. While direct comparisons to the mature steel industry are complex, the efficiency of CNT production is a key area of research.

The Production Footprint

Within the family of advanced carbon nanomaterials, CNT production is becoming increasingly optimized.

Studies indicate that the synthesis of carbon nanotubes can have lower associated CO2 emissions per kilogram compared to alternatives like graphene or carbon black, the latter of which also requires higher loading in composites to achieve similar effects.

Understanding the Trade-offs: Why Steel Still Dominates

If CNTs are so remarkable, why aren't they used everywhere? The answer lies in the immense practical and economic gap between a nanoscale fiber and a macroscopic building material.

The Challenge of Scale and Purity

The exceptional properties of CNTs are measured on individual, near-perfect tubes in a lab. We cannot yet manufacture macroscopic objects, like a car chassis or a bridge girder, made purely of CNTs.

Current production methods yield powders or tangled mats of nanotubes with varying purity, length, and types, whose bulk properties are a fraction of the theoretical potential.

The Prohibitive Cost Barrier

Steel is one of the most affordable engineering materials on the planet, costing a few dollars per kilogram.

In contrast, high-purity carbon nanotubes can cost hundreds or even thousands of dollars per gram. This cost difference means CNTs are only viable in applications where their extreme performance justifies the expense.

Issues with Dispersion and Integration

Due to powerful intermolecular forces, carbon nanotubes tend to clump together in what is known as agglomeration.

Separating these clumps and dispersing the nanotubes evenly throughout a host material (like a plastic or metal) is a major engineering challenge. Poor dispersion leads to weak spots and negates the potential benefits.

Isotropic vs. Anisotropic Properties

Steel is an isotropic material, meaning its strength and properties are the same in all directions. This makes it predictable and easy to design with.

CNTs are highly anisotropic. Their incredible strength and conductivity exist along their length, but not across their diameter. The properties of a CNT composite therefore depend entirely on how the tubes are aligned, adding significant complexity.

Making the Right Choice for Your Goal

The decision to use CNTs or steel is not a direct competition but a question of application and intent. You must choose the material that solves your specific problem.

- If your primary focus is extreme lightweighting and performance enhancement: CNTs, used as an additive in a composite material, are the clear choice for applications like aerospace components, high-end sporting goods, or advanced electronics.

- If your primary focus is cost-effective structural integrity at scale: Steel is, and will remain, the undisputed champion for construction, infrastructure, automotive frames, and general manufacturing.

- If your primary focus is creating a new class of "smart" materials: CNTs are a powerful tool for imparting electrical conductivity, thermal management, or sensing capabilities into otherwise inert materials like plastics, coatings, and textiles.

Ultimately, understanding the fundamental differences between a bulk structural metal and a nanoscale performance additive empowers you to select the right tool for the engineering task at hand.

Summary Table:

| Property | Carbon Nanotubes (CNTs) | Steel |

|---|---|---|

| Strength-to-Weight Ratio | Up to 100x greater | Benchmark |

| Electrical Conductivity | Superior to copper | Modest conductor |

| Thermal Conductivity | Superior to diamond | Modest conductor |

| Primary Application | High-performance additive | Bulk structural material |

| Cost | High ($100s-$1000s/gram) | Low ($/kilogram) |

Ready to Enhance Your Materials with Carbon Nanotube Technology?

KINTEK specializes in providing high-quality lab equipment and consumables for advanced material research and development. Whether you are developing next-generation composites, electronics, or smart materials, our expertise can help you integrate the superior properties of carbon nanotubes effectively.

Contact our experts today to discuss how our solutions can accelerate your R&D and bring your high-performance material projects to life.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Multi-zone Laboratory Tube Furnace

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How do you make a sputtering target? The Complete Guide to Manufacturing High-Performance Targets

- What is the RF frequency used for sputtering process? The Standard 13.56 MHz Explained

- What are the chemical properties of silicon carbide? Discover Its Extreme Chemical Inertness and Stability

- Can carbon nanotubes be used as catalyst support? Yes, for superior catalytic performance.

- How thick is the thin film color? Unlocking the Nanometer Scale of Iridescent Effects

- How can thin films be used as coating material? Enhance Surface Properties with Precision Engineering

- What are the factors that affect thin film? Master the 4 Key Pillars of Thin Film Engineering

- What is the sputtering target of gallium oxide? A Guide to High-Performance Ga₂O₃ Thin Films