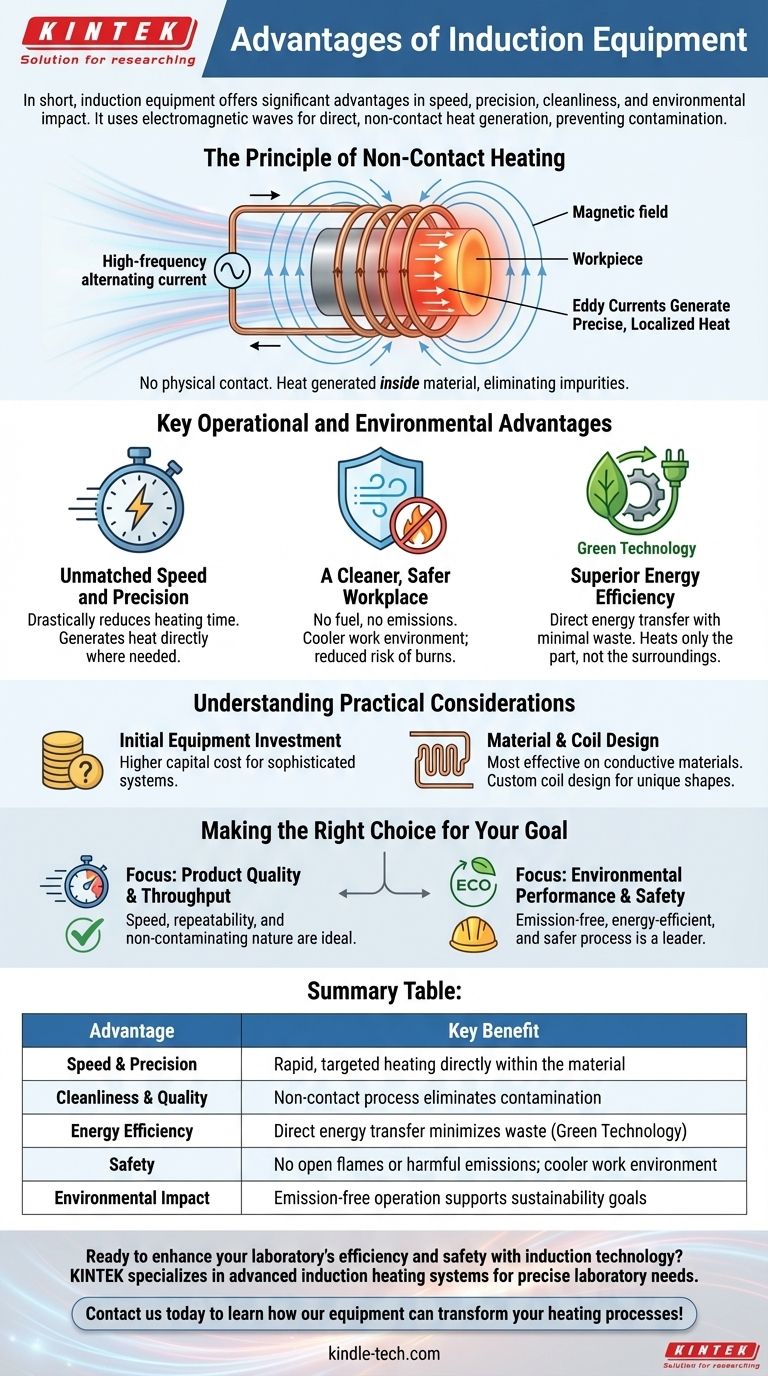

In short, induction equipment offers significant advantages in speed, precision, cleanliness, and environmental impact. Unlike traditional methods, it uses electromagnetic waves to generate heat directly within the material itself, eliminating direct contact with any flame and preventing product contamination.

The core advantage of induction technology is its ability to deliver highly targeted, rapid, and clean heat. This translates into superior product quality, a safer work environment, and a more environmentally friendly process compared to conventional heating methods.

The Principle of Non-Contact Heating

Induction heating is fundamentally different from traditional furnaces or torches. Understanding this principle is key to appreciating its benefits.

How Heat is Generated

Induction systems use a powerful, high-frequency alternating current that flows through a coil. This creates a dynamic and intense magnetic field around the coil.

When a conductive material (like metal) is placed within this field, the magnetic field induces electrical currents—known as eddy currents—inside the part. The resistance of the metal to the flow of these currents generates precise, localized heat.

Eliminating Contamination

Because heat is generated inside the part via this magnetic field, the material never touches a flame or external heating element. This complete lack of physical contact is crucial for eliminating impurities and contamination, ensuring a higher quality final product.

Key Operational and Environmental Advantages

The unique heating method of induction equipment leads to a cascade of benefits that impact everything from production speed to corporate sustainability goals.

Unmatched Speed and Precision

By generating heat directly where it's needed, induction is exceptionally fast. It drastically reduces the time required to bring a material to temperature compared to waiting for heat to transfer from an external source.

A Cleaner, Safer Workplace

Induction systems do not burn fuel or produce harmful emissions like smoke or fumes. This creates a much cleaner and safer environment for operators.

Furthermore, the heat is contained within the workpiece itself, which means the surrounding atmosphere and equipment do not heat up excessively. This reduces the risk of accidental burns and creates a more comfortable workspace.

Superior Energy Efficiency

This technology is considered a green technology because of its remarkable efficiency. Energy is transferred directly to the product with minimal waste. Unlike a traditional furnace that must heat the entire chamber, induction focuses energy only on the part being processed.

Understanding the Practical Considerations

While the advantages are clear, a balanced perspective is necessary for making an informed decision. No technology is the perfect solution for every single application.

Initial Equipment Investment

Induction systems are sophisticated pieces of equipment. The initial capital cost can be higher than that of simpler, traditional heating methods like gas-fired furnaces or torches.

Material and Coil Design

Induction heating is most effective on electrically conductive materials. The specific geometry of the part being heated also influences the design of the induction coil, which may need to be customized for unique or complex shapes to ensure even heating.

Making the Right Choice for Your Goal

Ultimately, the decision to use induction equipment should be driven by your specific operational priorities.

- If your primary focus is product quality and throughput: The speed, repeatability, and non-contaminating nature of induction heating make it an ideal choice.

- If your primary focus is environmental performance and safety: Induction is a clear leader, offering an emission-free process that is both energy-efficient and safer for your team.

Adopting induction technology is a strategic investment in a faster, cleaner, and more controlled heating process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Precision | Rapid, targeted heating directly within the material |

| Cleanliness & Quality | Non-contact process eliminates contamination |

| Energy Efficiency | Direct energy transfer minimizes waste (Green Technology) |

| Safety | No open flames or harmful emissions; cooler work environment |

| Environmental Impact | Emission-free operation supports sustainability goals |

Ready to enhance your laboratory's efficiency and safety with induction technology?

KINTEK specializes in advanced lab equipment, including induction heating systems, designed to meet the precise needs of modern laboratories. Our solutions deliver the speed, cleanliness, and precision you need to improve product quality and achieve your sustainability goals.

Contact us today to learn how our induction equipment can transform your heating processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Anti-Cracking Press Mold for Lab Use

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes