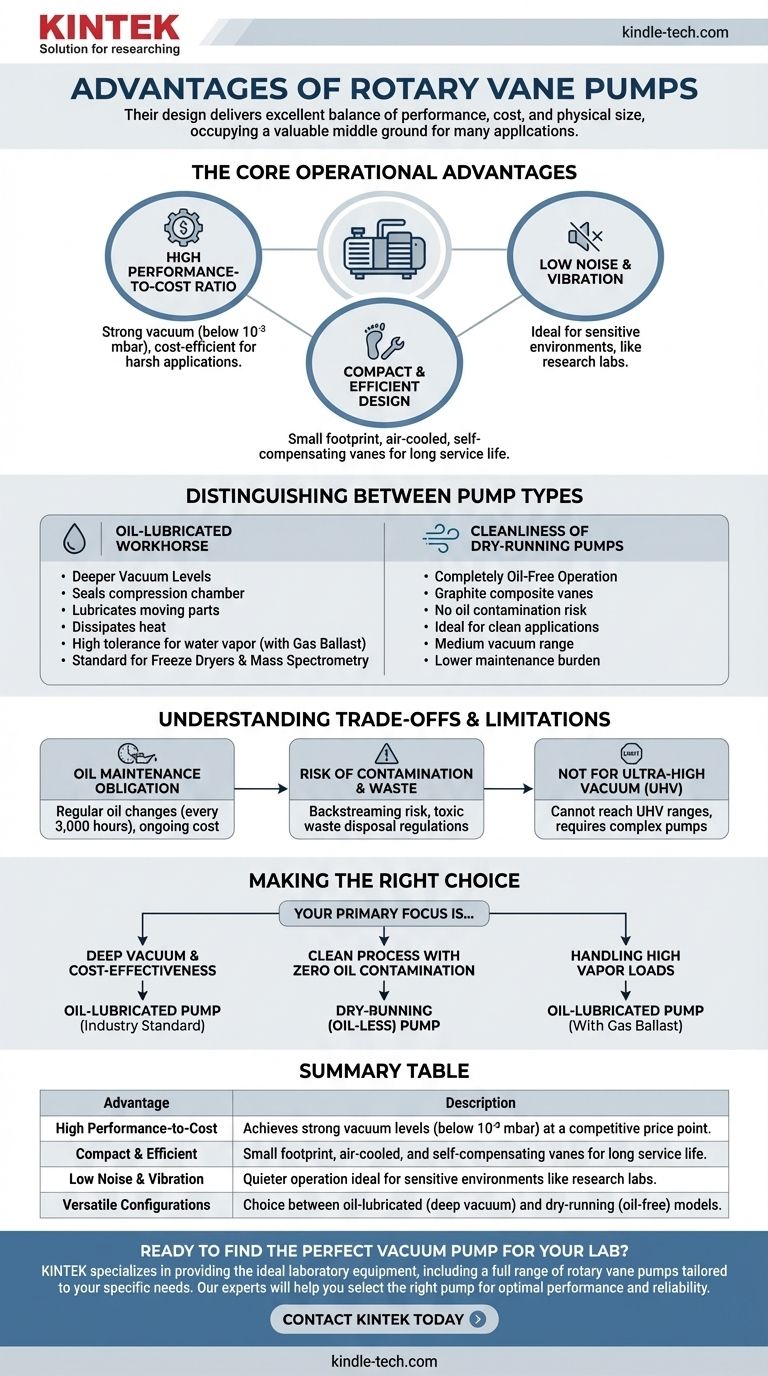

In short, the primary advantages of rotary vane pumps are their excellent balance of performance, cost, and physical size. They deliver strong, consistent vacuum levels in a compact, quiet, and relatively inexpensive package, making them one of the most versatile and widely used vacuum technologies available.

While many pump technologies force a choice between cost and performance, rotary vane pumps occupy a valuable middle ground. They offer a cost-effective path to achieving a high vacuum, making them the default choice for a vast range of industrial and laboratory applications.

The Core Operational Advantages

Rotary vane pumps are a type of positive-displacement pump. Their design involves a rotor with sliding vanes mounted eccentrically inside a cylindrical cavity, which creates expanding and contracting volumes to move gas from the inlet to the outlet. This simple, effective mechanism is the source of their key benefits.

High Performance-to-Cost Ratio

Rotary vane pumps are capable of producing a strong, consistent vacuum, often reaching pressures below 10⁻³ mbar.

This level of performance from a single, mechanically simple unit is difficult to achieve with other technologies at a similar price point. This makes them an exceptionally cost-efficient choice for applications requiring a harsh or deep vacuum.

Compact and Efficient Design

These pumps are typically air-cooled and have a small physical footprint, making them easy to integrate into larger systems or place on a lab bench.

The internal design, which features sliding vanes that self-compensate for wear, ensures they maintain peak performance over a long service life. This inherent durability contributes to a lower total cost of ownership.

Low Noise and Vibration

Compared to many other types of vacuum pumps, rotary vane models operate with significantly lower noise and vibration levels.

This is a critical advantage in sensitive environments like research labs, where noise can be disruptive, or in systems where mechanical vibration could interfere with precise measurements.

Distinguishing Between Pump Types

The most critical distinction to understand is between oil-lubricated and dry-running (oil-less) rotary vane pumps. The choice between them defines the pump's ultimate capabilities and maintenance requirements.

The Oil-Lubricated Workhorse

In these pumps, a specialized oil serves three crucial functions: sealing the compression chamber for higher vacuum, lubricating moving parts to prevent wear, and dissipating heat.

This design allows them to achieve deeper vacuum levels and provides a high tolerance for water vapor, especially when equipped with a feature known as a gas ballast. They are the standard for applications like freeze dryers and mass spectrometry.

The Cleanliness of Dry-Running Pumps

Dry-running, or oil-less, pumps are engineered with materials like graphite composites for the vanes, eliminating the need for oil. This design ensures completely oil-free operation.

They are the ideal choice for applications where even trace amounts of oil contamination are unacceptable. While they typically operate in the medium vacuum range, their maintenance burden is lower due to the absence of oil changes.

Understanding the Trade-offs and Limitations

No technology is perfect. Acknowledging the trade-offs of rotary vane pumps is essential for making an informed decision. The primary considerations revolve around the use of oil in lubricated models.

The Oil Maintenance Obligation

Oil-lubricated pumps require regular oil changes (typically after every 3,000 hours of operation) to maintain performance and prevent premature wear.

Failing to adhere to this maintenance schedule will degrade the pump's vacuum capability and can lead to catastrophic failure. This represents an ongoing operational cost and labor requirement.

Risk of Contamination and Waste

In lubricated pumps, there is always a small risk of oil "backstreaming" from the pump into the vacuum chamber, which can contaminate sensitive processes or samples.

Furthermore, the used pump oil is considered toxic waste and must be handled and disposed of according to strict regulations, adding an element of complexity and environmental responsibility.

Not for Ultra-High Vacuum

While excellent for "high vacuum" applications, rotary vane pumps cannot reach the "ultra-high vacuum" (UHV) ranges required for fields like semiconductor manufacturing or particle physics. Those applications demand more complex and expensive pump technologies, such as turbomolecular or ion pumps.

Making the Right Choice for Your Application

Selecting the correct pump depends entirely on your specific goals for vacuum level, process cleanliness, and maintenance tolerance.

- If your primary focus is deep vacuum and cost-effectiveness: An oil-lubricated rotary vane pump is the industry standard, provided you can accommodate the required oil maintenance schedule.

- If your primary focus is a clean process with zero oil contamination: A dry-running (oil-less) rotary vane pump is the necessary choice for your medium-vacuum application.

- If your primary focus is handling high vapor loads: An oil-lubricated pump equipped with a gas ballast offers superior performance and durability for removing solvents and water vapor.

Ultimately, rotary vane pumps provide a powerful and reliable foundation for a huge spectrum of scientific and industrial vacuum systems.

Summary Table:

| Advantage | Description |

|---|---|

| High Performance-to-Cost | Achieves strong vacuum levels (below 10⁻³ mbar) at a competitive price point. |

| Compact & Efficient | Small footprint, air-cooled, and self-compensating vanes for long service life. |

| Low Noise & Vibration | Quieter operation ideal for sensitive environments like research labs. |

| Versatile Configurations | Choice between oil-lubricated (deep vacuum) and dry-running (oil-free) models. |

Ready to find the perfect vacuum pump for your lab?

KINTEK specializes in providing the ideal laboratory equipment, including a full range of rotary vane pumps tailored to your specific needs for vacuum level, process cleanliness, and maintenance requirements. Our experts will help you select the right pump—whether oil-lubricated for deep vacuum or dry-running for a clean process—ensuring optimal performance and reliability for your applications.

Contact KINTEK today to discuss your project and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How do magnets enhance the sputtering rate in magnetron sputtering process and improve the thin film quality? Boost Deposition Speed & Film Quality

- What is the difference between electric arc furnace and plasma arc furnace? Choose the Right Tool for Your Heat Processing Needs

- What apparatus is used for heating in a lab? A Guide to Choosing the Right Tool

- Why is precise temperature control critical for nanoporous zirconia membranes? Master Phase Stability & Yield

- What are the disadvantages of graphite? Managing Brittleness and Reactivity in High-Temp Applications

- What are the factors affecting heat transfer efficiency? Optimize Your Thermal Management System

- What are the disadvantages of distilling? The Hidden Costs of Model Compression

- What is a good flux for brazing? Select the Right Chemical Agent for Strong, Reliable Joints