At its core, silicon carbide (SiC) offers a powerful combination of extreme hardness, high-temperature stability, and excellent thermal conductivity. These properties make it a superior material for applications where conventional metals and ceramics would fail, ranging from industrial furnace components to advanced semiconductor substrates.

Silicon carbide is not a single material but a versatile ceramic platform. Its key advantage lies in how different manufacturing processes can tailor its properties for specific, extreme-environment challenges, from withstanding intense mechanical wear to managing extreme heat.

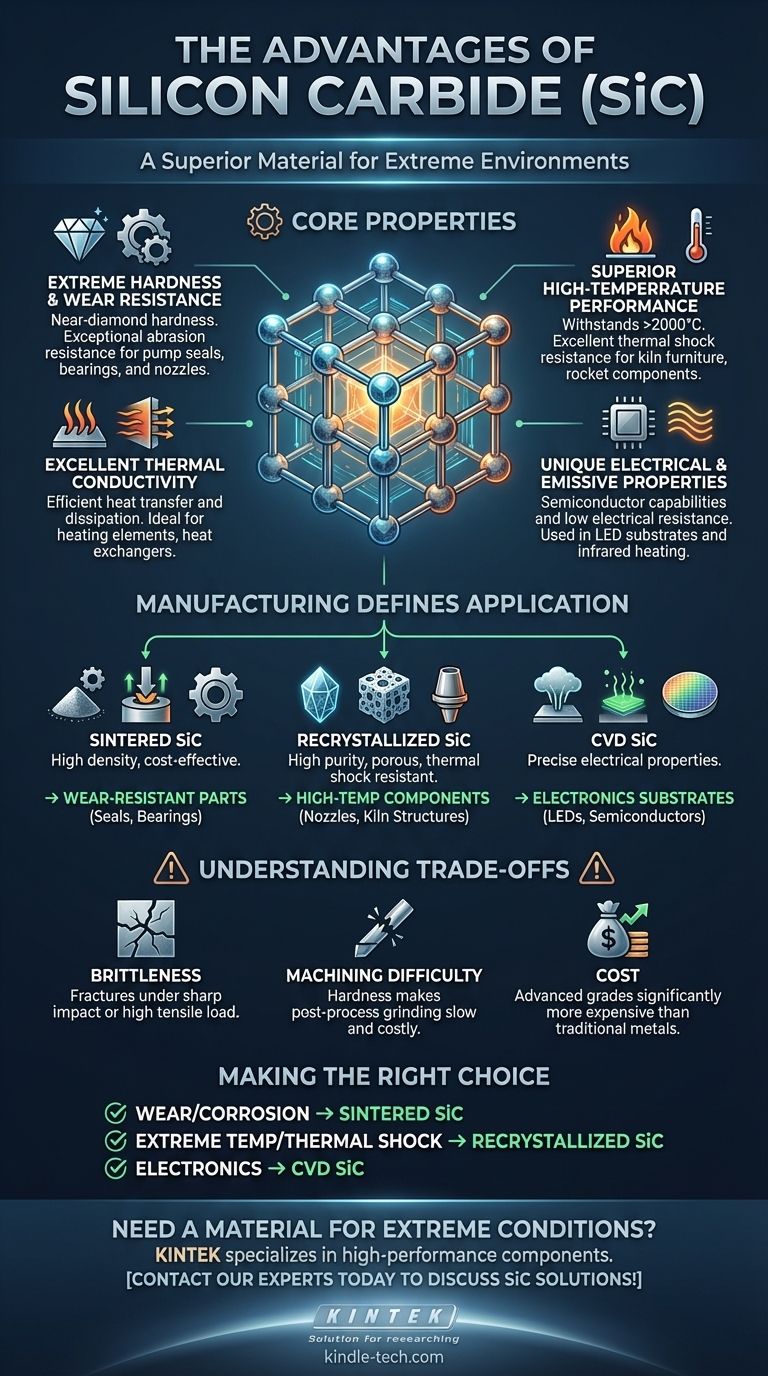

Unpacking the Core Properties of Silicon Carbide

Understanding the fundamental advantages of SiC explains its adoption in some of the most demanding engineering fields.

Extreme Hardness and Wear Resistance

Silicon carbide is one of the hardest synthetic materials available, surpassed only by materials like diamond. This extreme hardness directly translates to exceptional resistance to abrasion and wear.

Historically used for sandpapers and cutting tools, this property is now leveraged in high-performance mechanical parts. Components like pump seals, sliding bearings, and nozzles made from SiC last significantly longer in abrasive or high-friction environments.

Superior High-Temperature Performance

SiC demonstrates outstanding refractoriness, meaning it can withstand incredibly high temperatures—often in excess of 2000°C—without melting or degrading.

Coupled with its excellent resistance to thermal shock (sudden temperature changes), this makes it an ideal material for furnace linings, kiln furniture, guide rails, and even rocket engine components.

Excellent Thermal Conductivity

Unlike many ceramics that act as thermal insulators, silicon carbide has high thermal conductivity. It can transfer and dissipate heat very effectively.

This property is critical for its use in heating elements, which can heat up quickly and uniformly. It is also essential for heat exchangers, where efficient thermal transfer is the primary goal.

Unique Electrical and Emissive Properties

Depending on its purity and structure, SiC can act as a semiconductor. This has led to its widespread use as a substrate for manufacturing modern, high-efficiency light-emitting diodes (LEDs).

Furthermore, certain forms of SiC can be engineered to have very low electrical resistance, making them functional conductors. It also has a high blackness (emissivity), making it an efficient material for far-infrared heating plates.

How Manufacturing Method Defines the Application

The true versatility of silicon carbide is revealed in how it is produced. Different manufacturing methods create SiC variants with distinct properties optimized for specific uses.

Sintered SiC for Mechanical Durability

Atmospheric pressure sintered silicon carbide is valued for its high density and uniform internal structure. This process allows for the creation of complex shapes without significant size restrictions.

Because of its excellent overall properties and relatively lower production costs, it is the go-to choice for wear-resistant and corrosion-resistant parts like sealing rings and bearings.

Recrystallized SiC for Thermal Stability

Recrystallized silicon carbide is a highly pure crystalline form with significant porosity. This structure gives it exceptional thermal shock resistance.

Its ability to handle rapid temperature cycling without cracking makes it perfect for applications like high-temperature combustion nozzles, specialized kiln structures, and heat exchangers operating under intense conditions.

CVD SiC for Electrical Applications

Chemical Vapor Deposition (CVD) can produce SiC with very specific properties, including low electrical resistance. This control is vital for its use in the electronics industry.

CVD SiC is often used to create semiconducting substrates for LEDs or other electronic components where precise electrical characteristics are required.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of silicon carbide is crucial for making an informed decision.

Brittleness

Like most technical ceramics, silicon carbide is hard but also brittle. It does not bend or deform under stress like a metal; instead, it fractures. This requires careful design considerations to avoid sharp impacts or high tensile loads.

Machining Difficulty

Its extreme hardness makes silicon carbide very difficult and expensive to machine. Parts must often be formed into their final shape before the final sintering or densification stage, as post-process grinding is a slow and costly operation.

Cost

While some forms like sintered SiC can be cost-effective for their performance, advanced and highly purified grades of silicon carbide are significantly more expensive than traditional metals or lower-grade ceramics. The cost is justified only when its unique properties are essential for the application to succeed.

Making the Right Choice for Your Goal

Selecting the right type of silicon carbide depends entirely on your primary engineering challenge.

- If your primary focus is mechanical wear and corrosion resistance: Sintered SiC is the ideal choice for its high density, hardness, and cost-effectiveness in parts like seals and bearings.

- If your primary focus is extreme temperature and thermal shock: Recrystallized SiC provides the necessary purity and structural stability for furnace components, nozzles, and heat exchangers.

- If your primary focus is electronics and semiconductor applications: CVD SiC offers the precise control over electrical properties needed for substrates and specialized components.

Ultimately, silicon carbide empowers engineers to solve problems in environments too extreme for conventional materials.

Summary Table:

| Key Advantage | Primary Benefit | Ideal Application |

|---|---|---|

| Extreme Hardness | Superior wear & abrasion resistance | Seals, bearings, cutting tools |

| High-Temperature Stability | Withstands temperatures >2000°C | Furnace linings, kiln furniture |

| Excellent Thermal Conductivity | Efficient heat transfer & dissipation | Heating elements, heat exchangers |

| Semiconductor Properties | Enables high-efficiency electronics | LED substrates, power electronics |

Need a material that can handle extreme conditions? KINTEK specializes in high-performance lab equipment and consumables, including components made from advanced materials like silicon carbide. Our expertise can help you select the right material for your specific application, ensuring durability, efficiency, and reliability in your laboratory. Contact our experts today to discuss how silicon carbide can solve your most demanding challenges!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- CVD Diamond for Thermal Management Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments