To put it simply, freeze dryers are used in the food industry to preserve a wide range of products by removing moisture while retaining the vast majority of their original quality. This includes everything from fruits and vegetables for snacks to instant coffee, seasonings, and specialized items like baby food or meals for astronauts.

The core value of freeze-drying is its ability to create lightweight, shelf-stable foods that maintain their original nutritional value, flavor, and texture far better than any other drying method. It is a process of preservation without significant compromise.

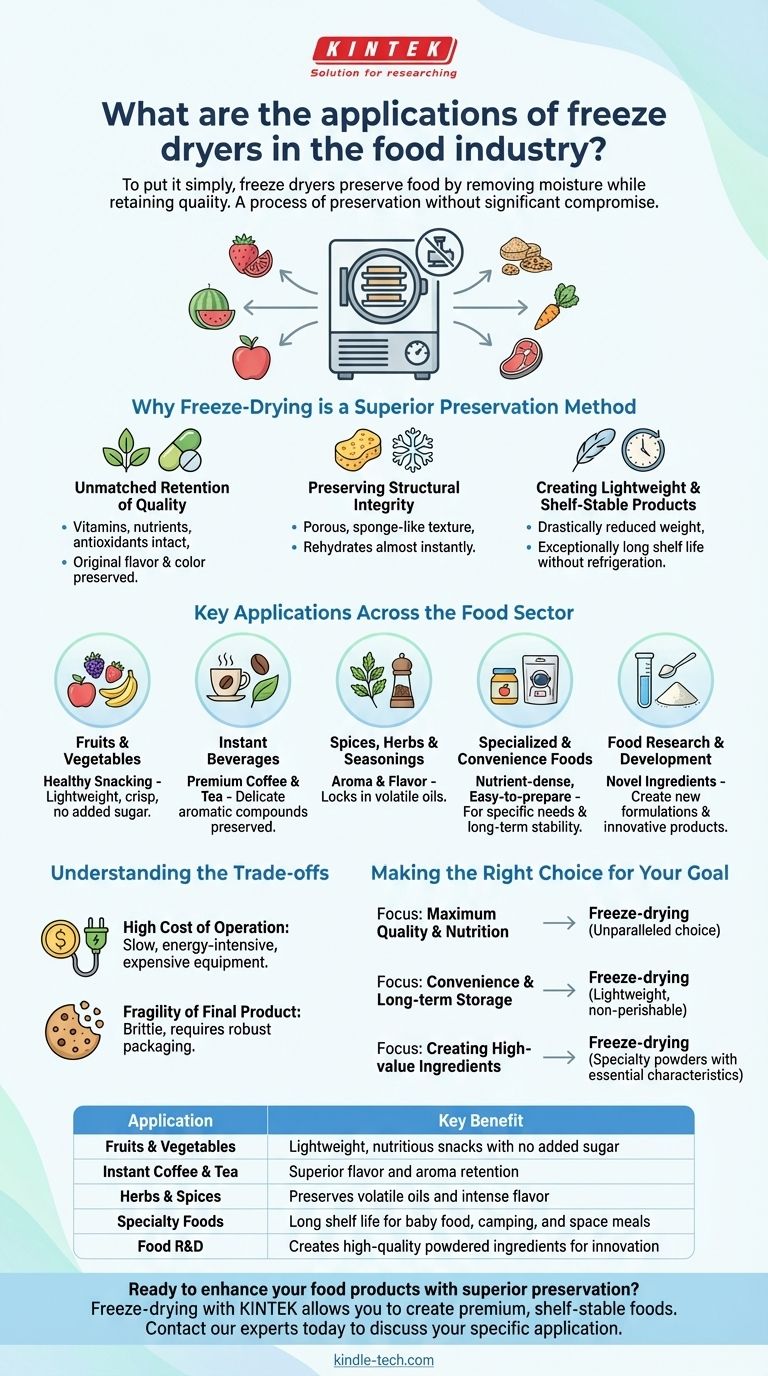

Why Freeze-Drying is a Superior Preservation Method

Freeze-drying, or lyophilization, is fundamentally different from simple dehydration. Instead of using heat, which degrades the product, it uses a vacuum and low temperatures to turn frozen water directly into vapor, a process called sublimation.

Unmatched Retention of Quality

The key advantage of avoiding high heat is the preservation of sensitive compounds. Vitamins, nutrients, and antioxidants that would be destroyed by conventional drying methods remain largely intact.

This process also maintains the food's original flavor and color, resulting in a final product that is far more vibrant and true-to-source.

Preserving Structural Integrity

Because the water is removed as a vapor from a frozen state, the food's cellular structure is left almost entirely undisturbed. This creates a porous, sponge-like texture.

This intact structure is why freeze-dried foods rehydrate almost instantly and retain a texture very close to their fresh state, unlike the shrunken, tough results of heat-based dehydration.

Creating Lightweight and Shelf-Stable Products

Removing nearly all the water content drastically reduces the weight of the food, making it easy and efficient to transport and store.

With the water removed, microbial activity comes to a halt. This gives freeze-dried foods an exceptionally long shelf life without the need for refrigeration or chemical preservatives.

Key Applications Across the Food Sector

The unique benefits of freeze-drying make it invaluable for a diverse range of food products where quality is paramount.

Fruits and Vegetables for Healthy Snacking

Freeze-drying transforms fruits like berries, apples, and bananas into crisp, lightweight snacks. This application is popular in the health food market because it creates a convenient, shelf-stable product with no added sugar or preservatives.

High-Quality Instant Beverages

The process is famously used to produce premium instant coffee and tea. It allows the delicate aromatic compounds to be preserved, resulting in a powder that dissolves easily and delivers a flavor far superior to spray-dried alternatives.

Spices, Herbs, and Seasonings

For ingredients where aroma and flavor are everything, freeze-drying is the ideal method. It locks in the volatile oils that give herbs and spices their distinct character.

Specialized and Convenience Foods

Freeze-drying is essential for creating nutrient-dense and easy-to-prepare foods for specific needs. This includes baby food, where nutritional integrity is critical, and meals for campers, hikers, and astronauts, where light weight and long-term stability are non-negotiable.

Food Research and Development

In food science labs, freeze dryers are used to create novel ingredients, test new formulations, and develop innovative products. The technology allows for the creation of powdered ingredients from nearly any food source.

Understanding the Trade-offs

While freeze-drying offers superior results, it is not a universal solution. The decision to use it involves balancing quality against practical constraints.

The High Cost of Operation

Freeze-drying is a slow, energy-intensive process. The equipment is expensive, and the cycle times can be long, making it a more costly preservation method compared to conventional heat or air drying.

Fragility of the Final Product

The porous structure that allows for easy rehydration also makes the final product very brittle and fragile. This necessitates more robust and careful packaging to prevent the food from being crushed into powder during shipping and handling.

Making the Right Choice for Your Goal

Selecting a preservation method depends entirely on what you want to achieve with the final product.

- If your primary focus is maximum quality and nutrition: Freeze-drying is the unparalleled choice for preserving the food's original color, flavor, and nutritional profile.

- If your primary focus is convenience and long-term storage: This technology creates lightweight, non-perishable products perfect for premium snacks, emergency kits, or pantry staples.

- If your primary focus is creating high-value ingredients: Freeze-drying enables the production of specialty powders and components that retain their essential characteristics for use in other food products.

Ultimately, freeze-drying empowers the food industry to offer preserved products that are defined by their quality, not by their shelf life.

Summary Table:

| Application | Key Benefit |

|---|---|

| Fruits & Vegetables | Lightweight, nutritious snacks with no added sugar |

| Instant Coffee & Tea | Superior flavor and aroma retention |

| Herbs & Spices | Preserves volatile oils and intense flavor |

| Specialty Foods | Long shelf life for baby food, camping, and space meals |

| Food R&D | Creates high-quality powdered ingredients for innovation |

Ready to enhance your food products with superior preservation?

Freeze-drying with KINTEK allows you to create premium, shelf-stable foods that retain their original flavor, color, and nutritional value far better than conventional methods. Whether you are developing healthy snacks, high-quality ingredients, or specialized meals, our lab equipment and expertise are here to support your goals.

Contact our experts today to discuss how a freeze dryer can benefit your specific application and add value to your product line.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- Does THC evaporate over time? The Truth About Potency Loss and Preservation

- What is freeze drying and how does it work? A Complete Guide to Lyophilization

- What happens during the freezing phase of lyophilization? Master the Critical First Step for Product Integrity

- What are the main steps involved in the freeze-drying process? A Guide to the 3 Key Stages