Hot pressing is a specialized manufacturing process used to create extremely dense, high-performance materials that cannot be produced by conventional methods. Its primary applications are in industries that demand superior mechanical strength and wear resistance, such as producing sintered brake pads for high-speed trains and motorcycles, clutch discs for heavy machinery, and advanced pore-free ceramics for optical or thermal components.

The core reason for using hot pressing is to achieve near-perfect material density. By applying intense pressure and heat simultaneously, the process eliminates internal voids, resulting in components with exceptional strength, heat resistance, and wear characteristics that are critical for demanding environments.

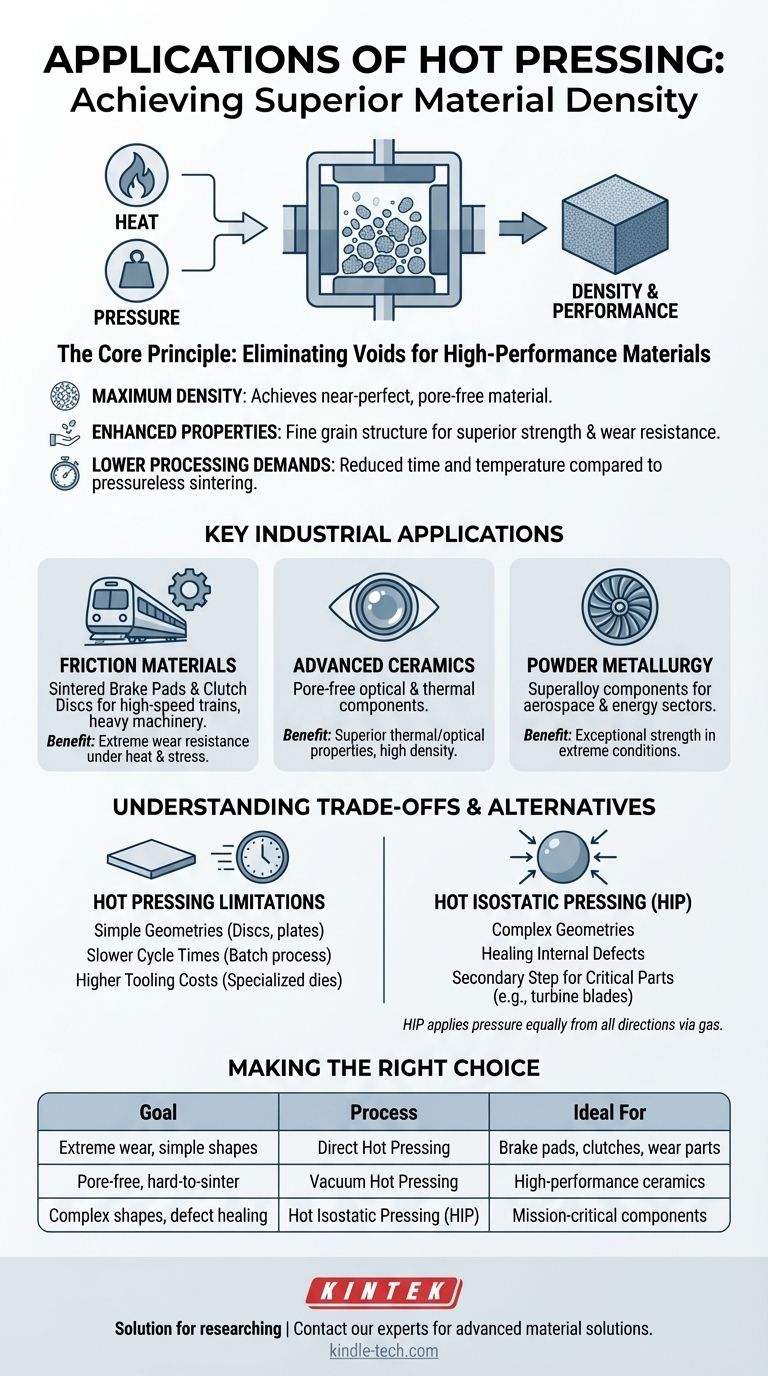

The Core Principle: Why Heat and Pressure Matter

Hot pressing fundamentally changes how materials consolidate. Unlike simply heating a powder (sintering), the addition of mechanical pressure during the thermal cycle forces particles together, accelerating the densification process.

Achieving Maximum Density

The primary goal of hot pressing is to produce a pore-free material. The applied pressure aids mass transfer between particles, effectively squeezing out the voids that would otherwise remain after standard sintering. This is critical for parts where porosity would compromise mechanical, thermal, or optical performance.

Enhancing Material Properties

This process results in a material with a very fine and uniform grain structure. Smaller grains inhibit the formation and propagation of cracks, leading to significantly improved strength, hardness, and resistance to fatigue and abrasion. The final products are higher quality components that can withstand rough operational environments.

Lowering Processing Demands

By combining heat and pressure, hot pressing can achieve full densification at lower temperatures and in less time compared to pressureless sintering. This not only reduces energy consumption but also prevents unwanted grain growth, preserving the fine microstructure that gives the material its superior properties.

Key Industrial Applications

The unique benefits of hot pressing make it the preferred method for several critical industrial components where performance and reliability are non-negotiable.

High-Performance Friction Materials

The friction material industry heavily relies on hot pressing to produce sintered metal components.

- Sintered Brake Pads: Used in high-speed trains, motorcycles, wind turbines, and ATVs.

- Sintered Clutch Discs: Used in heavy-duty trucks, tractors, ships, and other agricultural machines.

These applications demand materials that maintain structural integrity and consistent friction characteristics under extreme heat and mechanical stress.

Advanced Ceramics and Composites

Certain advanced ceramics have low diffusion coefficients, meaning their atoms don't move easily, making them very difficult to sinter into a dense state. Vacuum hot pressing is essential for creating pore-free parts from these materials, which are often used for their unique thermal or optical properties.

Powder Metallurgy and Superalloys

Hot pressing is also used to consolidate metal powders, especially superalloys, into solid forms. This is common in research and for producing specialized components that must perform under extreme conditions, such as in the aerospace or energy sectors.

Understanding the Trade-offs

While powerful, hot pressing is not a universal solution. Its advantages come with specific limitations that make it unsuitable for certain applications.

Geometric Constraints

The process relies on rigid dies to apply pressure, which generally limits the final parts to relatively simple geometries, such as discs, plates, and cylinders. Creating highly complex shapes is often impractical with this method.

Slower Cycle Times

Hot pressing is typically a batch process, where parts are made one at a time or in small groups. This results in slower production rates compared to high-volume manufacturing methods like cold pressing followed by furnace sintering.

Higher Tooling Costs

The dies and punches used in hot pressing must be made from materials that can withstand extreme temperature and pressure simultaneously. This makes the tooling expensive to manufacture and maintain, contributing to the overall cost of the process.

A Note on Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a related but distinct process. Instead of applying pressure from one direction (uniaxially), HIP uses a high-pressure gas to apply pressure equally from all directions.

The Key Difference

This isostatic pressure allows for the densification of parts with highly complex geometries that are impossible to form in a traditional hot press.

When HIP is Used

HIP is often used as a secondary step to remove any remaining porosity in critical components like cast turbine blades. It is also used to consolidate superalloy powders into complex shapes for aerospace and medical implants, where absolute material integrity is paramount.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on the performance requirements of the final component.

- If your primary focus is extreme wear and friction resistance in simple shapes: Direct hot pressing is the ideal choice for creating durable brake pads, clutches, and industrial wear parts.

- If your primary focus is achieving pore-free density in hard-to-sinter materials: Vacuum hot pressing provides the necessary conditions to create high-performance ceramics and composites.

- If your primary focus is densifying complex shapes or healing internal defects in castings: Hot Isostatic Pressing (HIP) is the superior technology for manufacturing mission-critical components.

Ultimately, choosing the right thermal consolidation method is key to engineering materials that meet their specific performance demands.

Summary Table:

| Application Area | Key Products | Primary Benefit |

|---|---|---|

| Friction Materials | Sintered Brake Pads, Clutch Discs | Extreme wear resistance, consistent performance under stress |

| Advanced Ceramics | Pore-free optical/thermal components | Superior thermal/optical properties, high density |

| Powder Metallurgy | Superalloy components for aerospace/energy | Exceptional strength under extreme conditions |

Need to develop high-performance materials for demanding applications?

KINTEK specializes in advanced laboratory equipment and consumables, including solutions for thermal processing and material synthesis. Whether you are researching advanced ceramics, developing new friction materials, or consolidating metal powders, our expertise can help you achieve superior material density and performance.

Contact our experts today to discuss how KINTEK can support your laboratory's specific needs in material science and manufacturing.

Visual Guide

Related Products

- Touchscreen Automatic Vacuum Heat Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- How does the pressure control system of vacuum hot press equipment contribute to preventing material defects? Learn More

- What is the function of a vacuum-sealed, heated stainless steel container? Ensuring Integrity in LBE Corrosion Tests

- What advantages does a vacuum hot press offer for ZIF-62 glass? Achieve Large, Bubble-Free, High-Density Results

- How does the high-temperature and high-pressure environment provided by vacuum hot press equipment improve the interfacial bonding between Mo fibers and the TiAl matrix?

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?