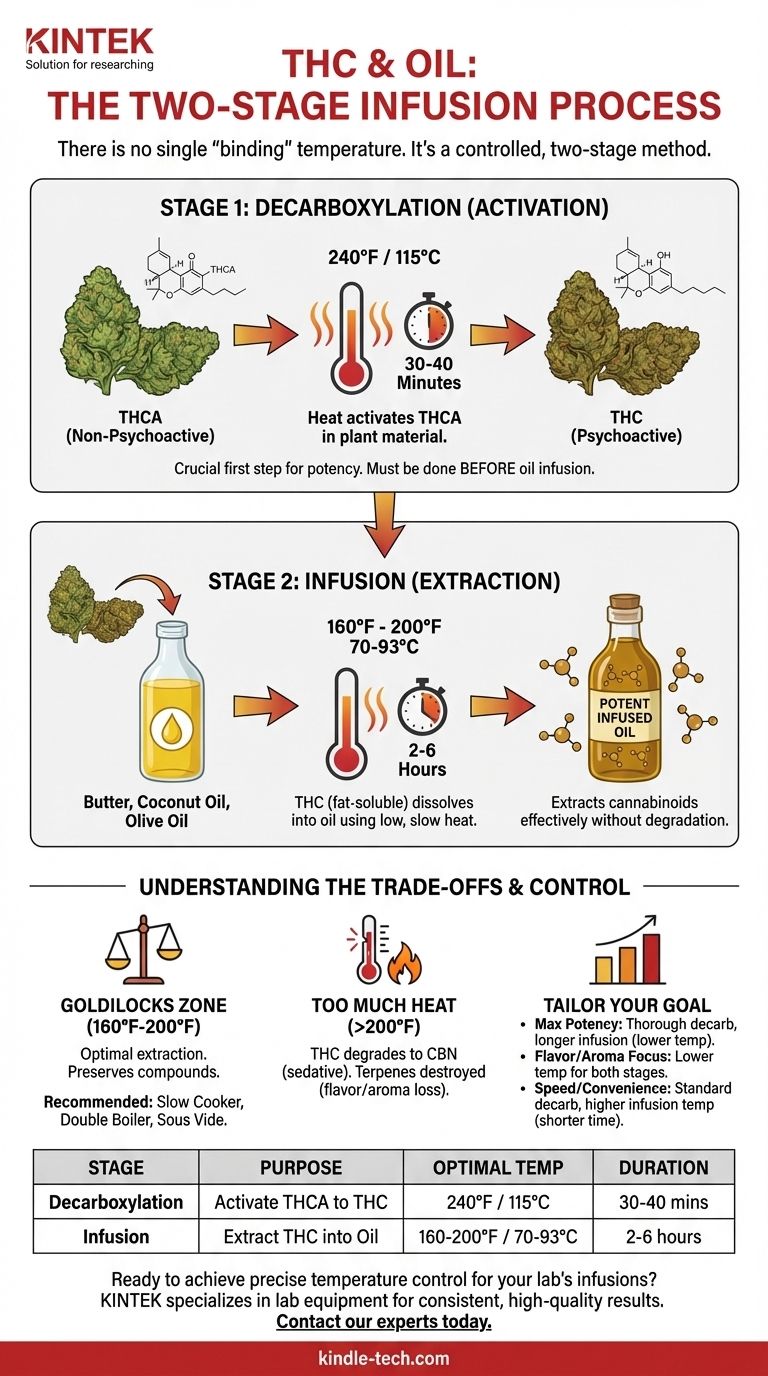

There is no single "binding" temperature for THC and oil. Instead, creating a potent infusion is a carefully controlled, two-stage process. The first stage uses a higher heat to "activate" the THC in the plant material, a process called decarboxylation. The second stage uses a lower, gentler heat to infuse that activated THC into the oil.

The core principle is to separate activation from infusion. You must first decarboxylate your cannabis to activate THC (typically around 240°F / 115°C). Only then should you infuse the material into oil at a lower temperature range of 160°F - 200°F (70-93°C) to effectively extract the cannabinoids without degrading them.

The Two-Stage Process: Activation and Infusion

Many people believe you can simply add cannabis to warm oil and get a potent result. This approach often leads to disappointment because it overlooks the most critical chemical conversion.

Step 1: Decarboxylation (Activation)

Raw cannabis contains very little psychoactive THC. Instead, it is filled with its acidic precursor, THCA.

THCA is not psychoactive. To create the desired effects, you must convert it into THC by gently heating it. This process is called decarboxylation.

This is the most common step people miss. You must decarboxylate your cannabis before it ever touches the oil for an efficient and potent infusion. The standard guideline is to heat the cannabis in an oven at 240°F (115°C) for 30 to 40 minutes.

Step 2: Infusion (Extraction)

Once your cannabis is decarboxylated, the THC is active and ready to be extracted. Because THC is lipophilic (fat-soluble), it readily dissolves into fats like butter, coconut oil, or olive oil.

The goal of this stage is to use gentle heat to encourage the THC to leave the plant material and dissolve into the oil.

The optimal temperature range for infusion is between 160°F and 200°F (70-93°C). This is a "low and slow" process, typically lasting anywhere from 2 to 6 hours depending on your method and desired strength.

Understanding the Trade-offs

Temperature control is the single most important factor in this entire process. Deviating from the optimal ranges can drastically change your final product.

The "Goldilocks Zone"

Staying within the 160°F - 200°F infusion range is crucial. This is warm enough to facilitate a thorough extraction but low enough to protect the compounds you just activated.

Using a slow cooker, a double boiler, or a sous vide precision cooker is highly recommended over direct stovetop heat, which can easily create hot spots and scorch your material.

The Danger of Too Much Heat

Exceeding 200°F during infusion is counterproductive. While it might seem like more heat means faster infusion, it actually begins to damage your product.

THC has a boiling point of around 315°F (157°C), but it begins to degrade at temperatures much lower than that. Excessive heat can convert your valuable THC into another cannabinoid called CBN, which is known for its sedative properties rather than psychoactivity.

Furthermore, high heat destroys terpenes, the aromatic compounds responsible for the plant's distinct smell and flavor, which also contribute to its nuanced effects.

How to Apply This to Your Project

By understanding the two distinct stages, you can tailor the process to your specific goal.

- If your primary focus is maximum potency: Decarboxylate thoroughly (240°F for 40 minutes) and infuse at the lower end of the range (160-180°F) for a longer period (4-6 hours) to ensure a complete extraction.

- If your primary focus is preserving flavor and aroma: Use the lowest effective temperatures for both steps. Consider decarboxylating at 225°F for 60 minutes and infusing at no higher than 170°F for a few hours.

- If your primary focus is speed and convenience: Use the standard 240°F decarb for 30-40 minutes and infuse closer to 200°F for a shorter duration (1-2 hours), but accept that you will sacrifice some of the more delicate terpenes.

By mastering these two distinct temperature stages, you gain complete control over the potency and quality of your infusions.

Summary Table:

| Stage | Purpose | Optimal Temperature Range | Duration |

|---|---|---|---|

| Decarboxylation | Activates THCA into psychoactive THC | 240°F / 115°C | 30-40 minutes |

| Infusion | Extracts activated THC into the oil | 160°F - 200°F / 70°C - 93°C | 2-6 hours |

Ready to achieve precise temperature control for your lab's infusions?

KINTEK specializes in the lab equipment and consumables you need for consistent, high-quality results. Whether you're developing new formulations or ensuring product quality, our precise ovens and heating solutions are designed for the exact thermal control required in cannabis processing.

Contact our experts today to find the right equipment for your laboratory's specific needs and elevate your infusion process.

Visual Guide

Related Products

- Touchscreen Automatic Vacuum Heat Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Double Plate Heating Press Mold for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is the function of a vacuum hot press furnace? Achieve High Densification in Al-Ti-Zr Synthesis

- What is the function of a vacuum-sealed, heated stainless steel container? Ensuring Integrity in LBE Corrosion Tests

- Why is a laboratory hot press required after the spray-coating of polymer-ceramic composite electrolytes? Essential density.

- What advantages does a vacuum hot press offer for ZIF-62 glass? Achieve Large, Bubble-Free, High-Density Results

- How does a laboratory vacuum hot-pressing furnace achieve the densification of ZrB2-SiC through synergistic control?