At its core, a hot press machine is a high-precision industrial tool designed to apply controlled heat and pressure to materials. Unlike simpler presses, its primary function is to execute highly specific thermal processes—like bonding, laminating, or forming—with exceptional accuracy, often utilizing advanced features like pulse heating and machine vision for perfect alignment.

The defining characteristic of a modern hot press machine is not simply its ability to apply heat and pressure, but its capacity to do so with exceptional, digitally-controlled precision. Its primary purpose is to ensure perfect alignment and repeatable thermal bonding for high-value components.

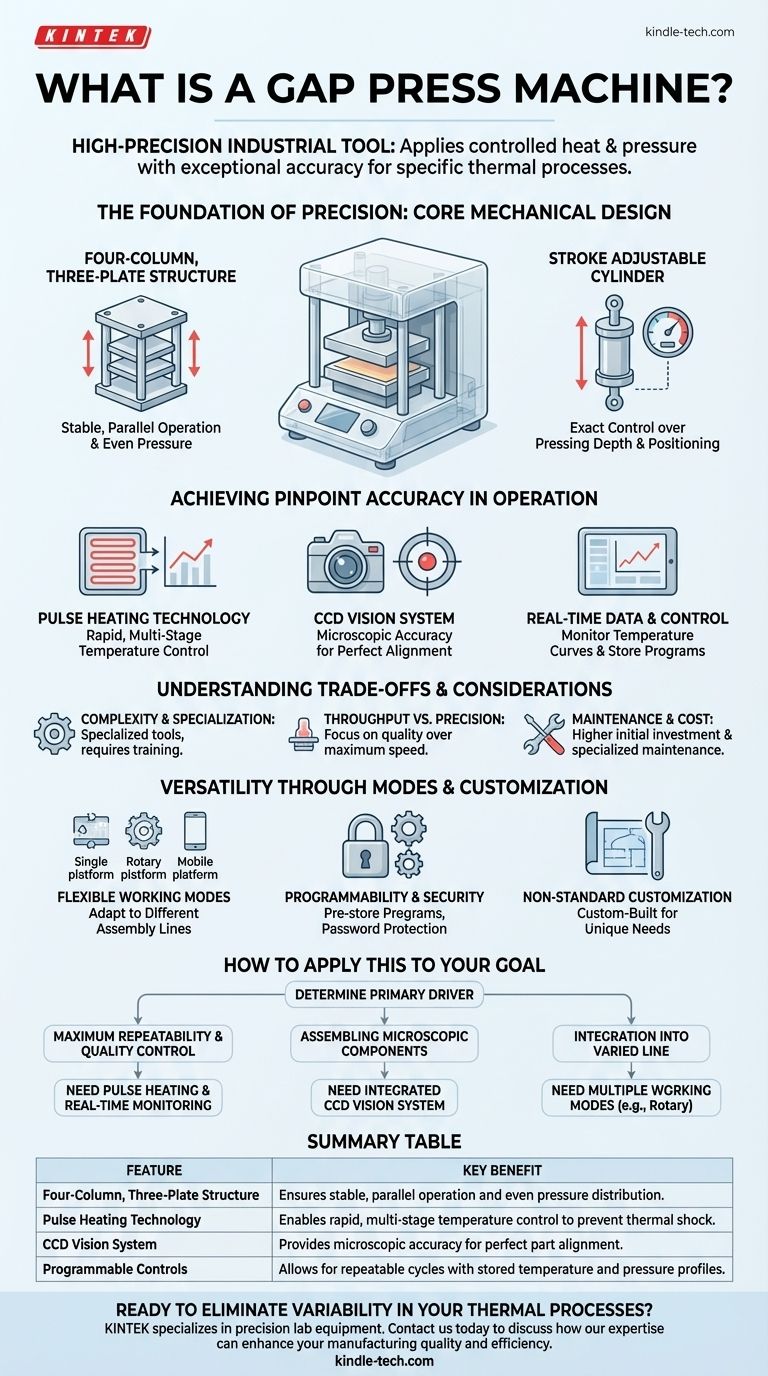

The Foundation of Precision: Core Mechanical Design

The machine's physical structure is the starting point for its accuracy. Every component is designed to ensure stability and repeatable motion under thermal and physical stress.

The Four-Column, Three-Plate Structure

This robust design provides a stable and parallel framework. This structure is critical for maintaining high precision and even pressure distribution across the entire working surface during the pressing operation.

Stroke Adjustable Cylinder

This feature allows for exact control over the pressing depth and positioning. By adjusting the cylinder's stroke, operators can ensure the machine applies force precisely where needed, which is vital for delicate or multi-stage processes.

Achieving Pinpoint Accuracy in Operation

The true value of a hot press machine lies in its sophisticated control systems. These systems work in concert to eliminate guesswork and ensure every cycle is identical to the last.

Pulse Heating Technology

This is a key technology for precise thermal management. Instead of simple on/off heating, pulse heating allows for rapid temperature ramping and multi-stage temperature control within a single process, preventing thermal shock to sensitive components.

The CCD Vision System

For tasks requiring perfect alignment, an integrated CCD (Charge-Coupled Device) vision system is used. This camera system helps the operator or an automated process to align parts with microscopic accuracy before the pressing cycle begins.

Real-Time Data and Control

Operators can monitor the entire process through a touch-operated interface. This system displays a real-time temperature curve and allows for the storage of multiple programs, each with unique temperature stages and pressure profiles.

Understanding the Trade-offs and Considerations

While powerful, these machines represent a specific engineering choice. Understanding their limitations is key to using them effectively.

Complexity and Specialization

The high precision of these machines comes from their complexity. They are not general-purpose shop presses but are specialized instruments designed for specific production tasks, requiring trained operators.

Throughput vs. Precision

Features like CCD alignment and multi-stage heating profiles guarantee quality but can increase cycle time. The focus is on perfect execution for each part rather than maximum speed.

Maintenance and Cost

Advanced components like vision systems and precision temperature controllers increase the initial investment and may require specialized maintenance compared to simpler hydraulic or mechanical presses.

Versatility Through Modes and Customization

Modern hot press machines are designed to adapt to different production environments and requirements, offering a high degree of flexibility.

Flexible Working Modes

These machines are not limited to a single configuration. They can be equipped with various platforms, including single, rotary, and left-right mobile workstations, to integrate smoothly into different assembly lines.

Programmability and Security

The ability to pre-store multiple programs for different jobs reduces setup time and human error. Program password protection ensures that validated process parameters cannot be accidentally changed.

Non-Standard Customization

For unique production needs, these machines can be custom-built. This allows manufacturers to specify the exact features, dimensions, and control parameters required for their specific application.

How to Apply This to Your Goal

To determine if this technology fits your needs, consider the primary driver of your manufacturing process.

- If your primary focus is maximum repeatability and quality control: You need a machine with pulse heating and real-time temperature curve monitoring.

- If your primary focus is assembling microscopic or complex components: The integrated CCD vision system is the non-negotiable feature for ensuring accurate alignment.

- If your primary focus is integrating into a varied production line: Prioritize a model offering multiple working modes, like rotary or mobile platforms, for greater flexibility.

Ultimately, a hot press machine is an investment in precision, designed to eliminate variability in heat-based assembly and manufacturing processes.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Four-Column, Three-Plate Structure | Ensures stable, parallel operation and even pressure distribution. |

| Pulse Heating Technology | Enables rapid, multi-stage temperature control to prevent thermal shock. |

| CCD Vision System | Provides microscopic accuracy for perfect part alignment. |

| Programmable Controls | Allows for repeatable cycles with stored temperature and pressure profiles. |

Ready to Eliminate Variability in Your Thermal Processes?

KINTEK specializes in precision lab equipment, including advanced hot press machines. Whether your primary focus is maximum repeatability, assembling microscopic components, or seamless production line integration, our solutions are engineered for your success.

Contact us today to discuss how our expertise can enhance your manufacturing quality and efficiency.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Double Plate Heating Press Mold for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity

- Which features of vacuum hot pressing equipment are utilized by the dual-step vacuum hot press process? Optimize AlMgTi