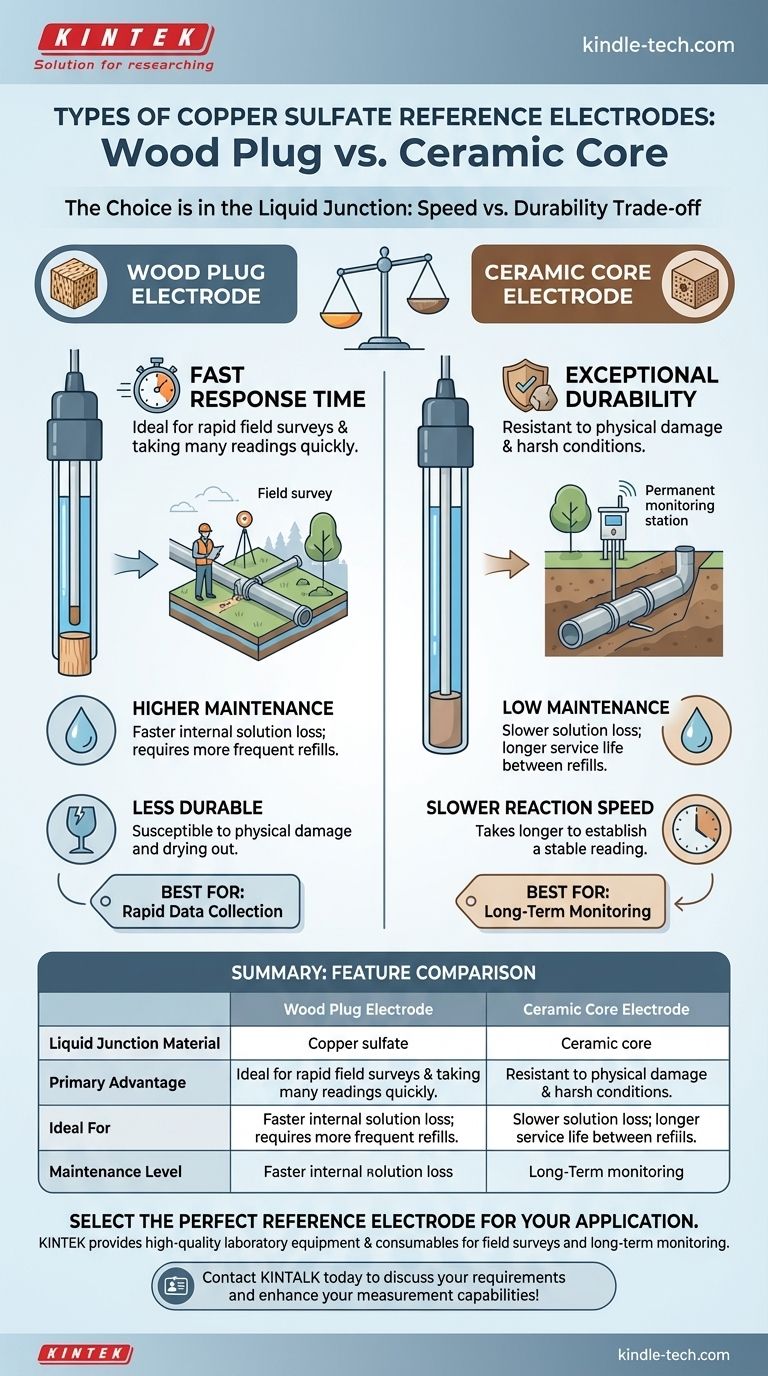

At its core, the choice in copper sulfate reference electrodes comes down to two main designs. The primary types are distinguished by the material used for the liquid junction: one features a porous wood plug, and the other uses a more durable ceramic core. This single component difference dictates the electrode's practical performance and suitability for different applications.

The decision between a wood plug and a ceramic core copper sulfate electrode is not about electrochemical accuracy, as both provide an identical reference potential. Instead, it is a critical trade-off between measurement speed and long-term physical durability.

The Role of the Liquid Junction

A reference electrode's purpose is to provide a stable, constant potential against which the potential of another material can be measured. This is fundamental to applications like cathodic protection surveys.

The liquid junction is the porous interface that allows for ionic conductivity between the electrode's internal copper sulfate solution and the external environment (like soil or water) you are measuring. It completes the electrical circuit without allowing the internal solution to quickly leak out or become contaminated.

The material used for this junction—wood or ceramic—is the key differentiator between the two electrode types.

A Detailed Comparison of Plug Types

The Wood Plug Electrode

This design uses a porous wood plug, often made of Douglas fir, to create the liquid junction. Its high porosity allows for a very quick ionic connection with the environment.

This results in a fast response time, making it ideal for taking many readings in rapid succession, such as during a field survey of a pipeline.

The Ceramic Core Electrode

This model uses a hard, porous ceramic material for the junction. The pores in the ceramic are typically smaller and less numerous than in a wood plug.

The primary advantages are its exceptional durability and minimal solution loss. This design is far more resistant to physical damage and drying out, but its lower porosity means it has a slightly slower reaction speed to establish a stable reading.

Performance vs. Practicality

While the stable electrochemical potential of both electrode types is identical, their practical performance characteristics are not. The choice is never about which one is more "accurate" under ideal lab conditions.

The difference is in their dynamic response and physical robustness. The wood plug is faster for spot checks, while the ceramic core is more reliable for long-term or harsh deployments.

Understanding the Trade-offs

Speed vs. Durability

This is the central trade-off. If you need to take readings quickly and move on, the fast stabilization of the wood plug is a significant advantage.

If the electrode will be used for permanent installation (e.g., buried) or in rough field conditions where it might be dropped or abraded, the physical robustness of the ceramic core is superior.

Maintenance and Solution Loss

Ceramic core electrodes lose their internal copper sulfate solution at a much slower rate than wood plug electrodes. This translates to lower maintenance and a longer service life between refills.

For applications involving continuous monitoring over weeks or months, the low-maintenance nature of the ceramic core is a decisive factor.

Making the Right Choice for Your Goal

Your specific measurement task should dictate your choice of electrode.

- If your primary focus is rapid field surveys: Choose the wood plug electrode for its fast response time, which allows for more efficient data collection.

- If your primary focus is long-term monitoring or permanent installation: Choose the ceramic core electrode for its superior durability and low maintenance requirements.

- If your primary focus is general-purpose use with an emphasis on longevity: The ceramic core is often the safer default choice due to its robustness, provided you can wait a few extra moments for the reading to stabilize.

Ultimately, selecting the correct reference electrode is about matching the tool's physical characteristics to the demands of the job.

Summary Table:

| Feature | Wood Plug Electrode | Ceramic Core Electrode |

|---|---|---|

| Liquid Junction Material | Porous Wood (e.g., Douglas Fir) | Hard, Porous Ceramic |

| Primary Advantage | Fast Response Time | High Durability & Low Maintenance |

| Ideal For | Rapid Field Surveys | Long-Term/Permanent Installation |

| Maintenance Level | Higher (Faster Solution Loss) | Lower (Slower Solution Loss) |

Select the Perfect Reference Electrode for Your Application

Choosing between a wood plug and a ceramic core electrode is critical for accurate and efficient cathodic protection measurements. KINTEK specializes in providing high-quality laboratory equipment and consumables, including durable reference electrodes tailored for field surveys or long-term monitoring.

Our experts can help you match the right tool to your specific needs, ensuring reliable data and optimal performance.

Contact KINTALK today to discuss your requirements and enhance your measurement capabilities!

Visual Guide

Related Products

- Copper Sulfate Reference Electrode for Laboratory Use

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

People Also Ask

- Is there a difference in performance between wood plug and ceramic core copper sulfate electrodes? Speed vs. Durability Explained

- What precautions should be taken when handling and using a copper sulfate reference electrode? Ensure Accurate Electrochemical Measurements

- How should a copper sulfate reference electrode be stored? A Guide to Short-Term & Long-Term Storage

- What are the advantages and disadvantages of the wood plug type copper sulfate reference electrode? Speed vs. Durability Explained

- What are the post-treatment procedures after using a copper sulfate reference electrode? Essential Steps for Accuracy & Longevity