Proper post-use care is essential for maintaining the accuracy and extending the life of a copper sulfate reference electrode. Immediately after use, you should clean the electrode's outer casing with a soft, damp cloth. Most importantly, carefully clean the microporous tip at the bottom, check the internal solution level, and refill it with a saturated copper sulfate solution if it has dropped below the specified mark.

The core purpose of all post-treatment procedures is to achieve two goals: protecting the porous tip from contamination and ensuring the internal copper sulfate solution remains saturated. These two factors are the foundation of the stable, reliable potential that makes accurate field measurements possible.

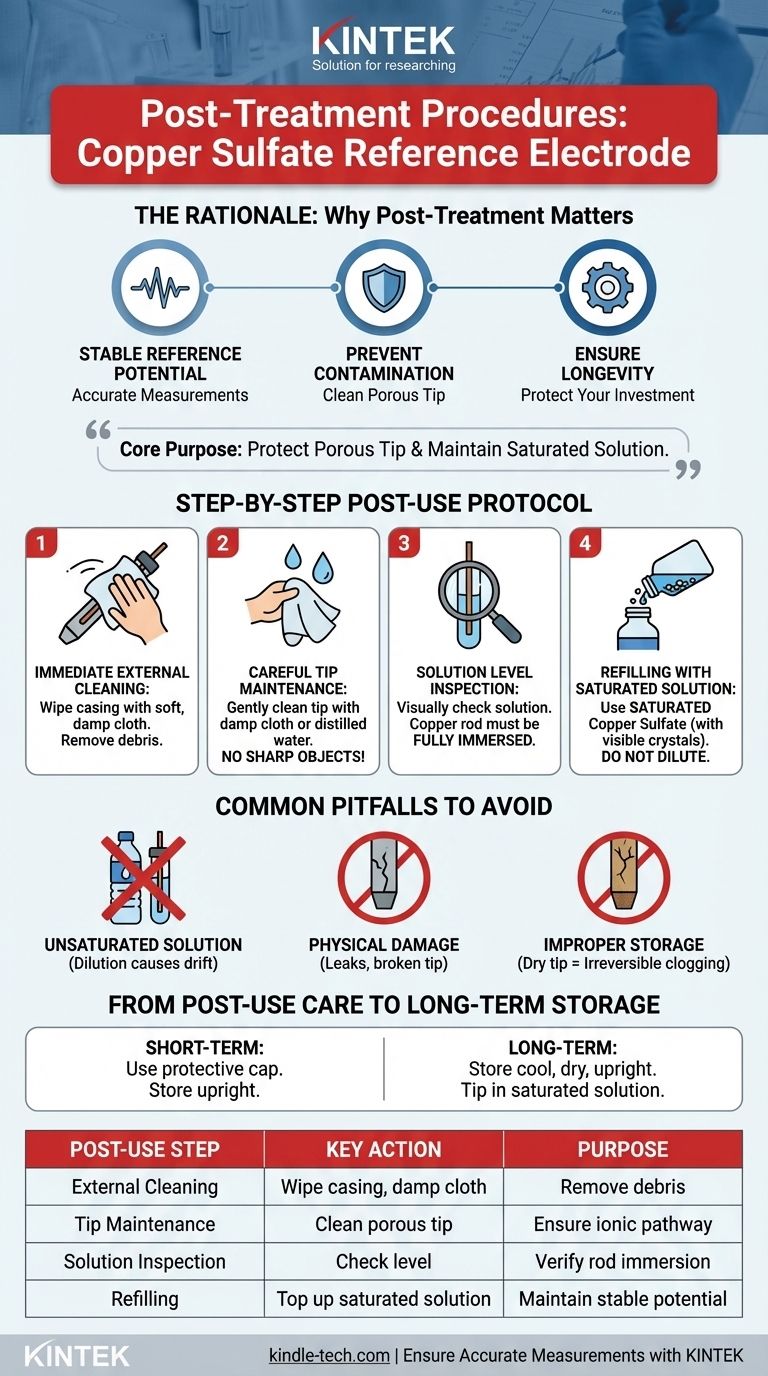

The Rationale: Why Post-Treatment Matters

A reference electrode isn't just a probe; it's an electrochemical half-cell that provides a stable reference point. Its reliability is not inherent—it is a direct result of meticulous handling and maintenance.

Maintaining a Stable Reference Potential

The electrode's potential is generated by a precise chemical equilibrium between the copper rod and a saturated copper sulfate solution.

If the solution becomes diluted or contaminated, this equilibrium shifts, causing the reference potential to drift. An unstable reference point makes all subsequent measurements unreliable.

Preventing Contamination and Clogging

The microporous plug at the tip is the critical interface between the internal solution and the external environment (e.g., soil or water).

If this plug becomes clogged with dirt or dries out, the ionic pathway is blocked. This prevents an accurate reading and can permanently damage the electrode.

Ensuring Equipment Longevity

Copper sulfate reference electrodes are designed to be durable, long-term instruments.

The ability to refill the solution means they can last for years. However, this longevity is entirely dependent on preventing physical damage and contamination through proper post-use care.

Step-by-Step Post-Use Protocol

Follow this simple but critical procedure immediately after completing your measurements in the field.

Step 1: Immediate External Cleaning

Use a soft, damp cloth to wipe away any soil, mud, or other impurities from the outer casing of the electrode. This prevents debris from drying and contaminating your equipment case or the electrode tip later.

Step 2: Careful Tip Maintenance

The porous tip is the most sensitive part of the electrode. Clean it gently with a damp cloth or rinse with distilled water.

Never use sharp objects to clean the tip, as scratches can permanently alter its performance and lead to inconsistent readings.

Step 3: Solution Level Inspection

Visually inspect the level of the copper sulfate solution through the transparent body of the electrode.

The solution must always be high enough to fully immerse the internal copper rod. A low level can lead to an unstable potential.

Step 4: Refilling with Saturated Solution

If the solution is low, unscrew the cap and refill the chamber.

It is critical to use a saturated copper sulfate solution. The best practice is to ensure excess copper sulfate crystals are always visible inside the electrode, confirming the solution remains saturated.

Common Pitfalls to Avoid

Mistakes in maintenance are the primary cause of reference electrode failure. Avoiding these common errors is crucial for data integrity.

The Risk of an Unsaturated Solution

Never top up the electrode with only distilled water. Doing so will dilute the solution, causing the reference potential to drift significantly and invalidating your measurements.

The Danger of Physical Damage

The electrode casing can crack if dropped or subjected to heavy impact. A cracked body will leak, making it impossible to maintain a stable internal environment. Likewise, a scratched or damaged tip cannot be repaired.

The Problem with Improper Storage

Never store the electrode dry for long periods. As the water evaporates from the tip, copper sulfate crystals will precipitate and clog the pores, often irreversibly.

Storing the electrode in direct sunlight or areas with large temperature swings can also affect the solution's stability and the electrode's potential.

From Post-Use Care to Long-Term Storage

Proper storage is the final step in post-treatment and is essential for ensuring the electrode is ready for its next use.

Short-Term Storage

For transport between job sites or overnight storage, ensure the protective cap is securely placed over the tip. This keeps the tip moist and clean. Always store the electrode in an upright position.

Long-Term Storage

For storage lasting weeks or months, keep the electrode in a cool, dry place away from direct sunlight.

The ideal method is to store it upright with its tip immersed in a small container of saturated copper sulfate solution. This ensures the plug remains wet, conductive, and free from crystallization.

Making the Right Choice for Your Goal

Your maintenance approach should align with your operational needs.

- If your primary focus is high-accuracy field measurements: Clean the tip immediately after every reading and perform periodic calibration checks against a known standard.

- If your primary focus is maximizing equipment lifespan: Make proper long-term storage your top priority, ensuring the tip never dries out.

- If you are troubleshooting inconsistent readings: Your first step is to confirm the tip is clean and the internal solution is saturated with excess crystals visible.

Consistent maintenance transforms your reference electrode from a simple tool into a reliable standard for all your electrochemical measurements.

Summary Table:

| Post-Use Step | Key Action | Purpose |

|---|---|---|

| External Cleaning | Wipe casing with a soft, damp cloth. | Remove debris to prevent contamination. |

| Tip Maintenance | Gently clean the porous tip with a damp cloth or distilled water. | Ensure an unobstructed ionic pathway. |

| Solution Inspection | Check the internal copper sulfate solution level. | Verify the copper rod is fully immersed. |

| Refilling | Top up with a saturated copper sulfate solution (with crystals). | Maintain a stable, reliable reference potential. |

Ensure your measurements are always accurate. Proper maintenance is key to reliable data. KINTEK specializes in high-quality laboratory equipment and consumables, including reference electrodes and the necessary solutions for their care. Let our experts help you select the right tools and establish best-practice maintenance protocols for your lab's specific needs.

Contact our team today to discuss your laboratory requirements and keep your equipment performing at its best.

Visual Guide

Related Products

- Copper Sulfate Reference Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Metal Disc Electrode Electrochemical Electrode

- Gold Disc Electrode

People Also Ask

- What is the expected lifespan of a copper sulfate reference electrode? Maximize Longevity with Proper Maintenance

- What are the pre-treatment steps before using a portable copper sulfate reference electrode? Ensure Accurate Corrosion Potential Measurements

- What are the advantages and disadvantages of the wood plug type copper sulfate reference electrode? Speed vs. Durability Explained

- What precautions should be taken when handling and using a copper sulfate reference electrode? Ensure Accurate Electrochemical Measurements

- How should a copper sulfate reference electrode be maintained? Ensure Accurate Electrochemical Measurements