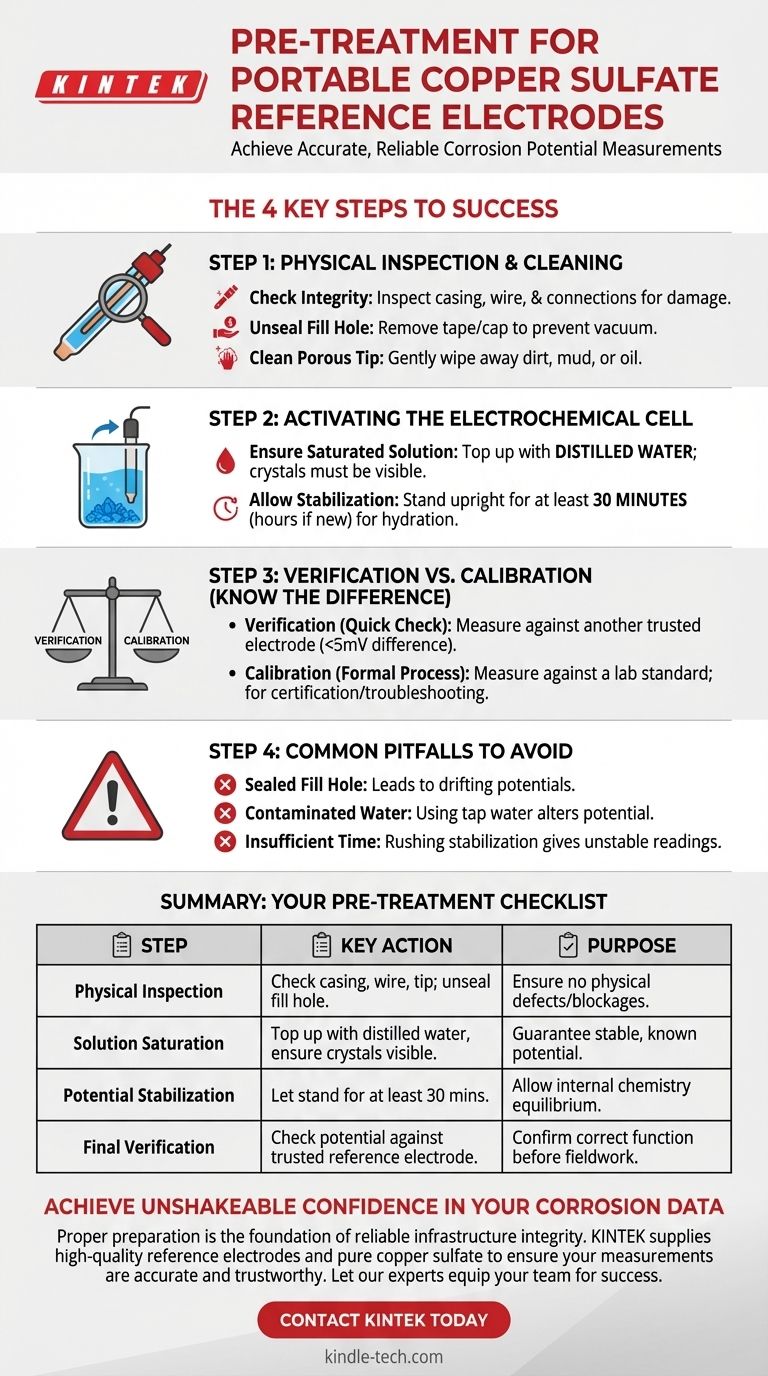

To properly prepare a portable copper sulfate reference electrode, you must follow four key steps: physical inspection, solution saturation, potential stabilization, and final verification. These procedures ensure the electrode is physically sound, its internal chemistry is correct, and it can provide the stable, accurate potential measurement required for reliable corrosion analysis.

The accuracy of your cathodic protection or corrosion potential measurements depends entirely on the stability of your reference electrode. Skipping these pre-treatment steps introduces uncertainty and can lead to misleading data, potentially masking serious infrastructure integrity issues.

The Foundation: Physical Inspection and Cleaning

Before any chemical preparation, a thorough physical check ensures the electrode is capable of performing its function. Damage or contamination can immediately invalidate your readings.

Check for Physical Integrity

Inspect the electrode's plastic casing for any cracks, chips, or damage. A compromised body can lead to solution leakage and contamination. Also, check the connection wire for any fraying, breaks, or signs of aging that could cause a poor electrical connection.

Unseal the Fill Hole

New electrodes, or those stored for travel, often have a seal (tape or a rubber cap) over the small fill hole. This must be removed before use. Leaving it on creates a vacuum as the solution tries to exit the porous tip, preventing a stable ionic pathway and causing wildly drifting readings.

Clean the Porous Tip

The porous plug at the bottom of the electrode is the bridge between the internal solution and the soil or electrolyte you are measuring. Check that it is free of dirt, mud, or oil. A clogged tip will obstruct the electrochemical circuit, resulting in slow, unstable, or incorrect measurements. Gently wipe it clean with a damp cloth.

Activating the Electrochemical Cell

The core of the electrode is the electrochemical reaction between the copper rod and the copper sulfate solution. Activating it correctly is non-negotiable for accuracy.

Ensure a Saturated Solution

The electrode's potential is only stable when the copper sulfate solution is fully saturated. Add distilled or deionized water until the level is appropriate, but ensure undissolved copper sulfate crystals remain visible at the bottom. The presence of these excess crystals is your visual confirmation of saturation. Using tap water can introduce chlorides and other ions that contaminate the solution and alter its potential.

Allow for Hydration and Stabilization

Once filled, the porous tip needs time to become fully wetted with the solution, and the electrode's internal potential needs to reach equilibrium. Immerse the tip in distilled water or let the electrode stand upright for at least 30 minutes before use. For a new or dry electrode, this may take several hours.

Understanding the Trade-offs: Verification vs. Calibration

The terms "verification" and "calibration" are often used interchangeably, but they represent different levels of rigor. Understanding the difference is key to efficient and reliable fieldwork.

The Purpose of Potential Verification

Verification is a quick confidence check. It involves measuring your electrode's potential against another trusted reference electrode. The difference between two healthy copper sulfate electrodes should be very small, typically less than 5 millivolts (mV). This confirms your electrode is functioning correctly before you begin a survey.

When Full Calibration is Necessary

A full calibration is a more formal process where you measure the electrode's potential against a standard of known potential in a controlled laboratory setting. This is rarely done in the field. Calibration is typically reserved for certifying new electrodes, troubleshooting a faulty one, or for high-stakes projects requiring traceable accuracy.

Common Preparation Pitfalls to Avoid

The most common sources of error are simple mistakes. The top three are:

- Forgetting to unseal the fill hole, which leads to drifting potentials.

- Using contaminated water (like tap water) to top up the solution.

- Not allowing sufficient time for the electrode to stabilize before taking a reading.

Applying This to Your Work

Your preparation method should align with the goal of your measurement. Rushing these steps is a false economy that produces unreliable data.

- If your primary focus is routine field checks: Prioritize physical inspection, ensuring the solution is saturated, and allowing at least 30 minutes of stabilization time.

- If your primary focus is a critical baseline survey or troubleshooting: Complete all steps, including a mandatory potential verification against a known, trusted electrode before heading to the field.

- If you are experiencing inconsistent readings: Stop and perform every pre-treatment step from the beginning. A poorly prepared electrode is the most common cause of unstable corrosion potential measurements.

Following these fundamental steps transforms your electrode from a simple tool into a precise and reliable scientific instrument.

Summary Table:

| Pre-Treatment Step | Key Action | Purpose |

|---|---|---|

| Physical Inspection | Check casing, wire, and porous tip for damage; remove fill hole seal. | Ensure no physical defects or blockages that cause unstable readings. |

| Solution Saturation | Top up with distilled water, ensuring excess copper sulfate crystals are visible. | Guarantee a stable, known electrochemical potential. |

| Potential Stabilization | Let electrode stand for at least 30 minutes (several hours if new/dry). | Allow internal chemistry to reach equilibrium for accurate measurement. |

| Final Verification | Check potential against a trusted reference electrode (<5mV difference). | Confirm the electrode is functioning correctly before fieldwork. |

Achieve Unshakeable Confidence in Your Corrosion Data

Properly prepared equipment is the foundation of reliable infrastructure integrity assessments. KINTEK specializes in supplying high-quality laboratory equipment and consumables, including reliable reference electrodes and pure copper sulfate, to ensure your field measurements are accurate and trustworthy.

Let our experts help you equip your team for success. Contact KINTEK today to discuss your specific laboratory and field monitoring needs.

Visual Guide

Related Products

- Copper Sulfate Reference Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Metal Disc Electrode Electrochemical Electrode

- Gold Disc Electrode

People Also Ask

- What is the expected lifespan of a copper sulfate reference electrode? Maximize Longevity with Proper Maintenance

- Is there a difference in performance between wood plug and ceramic core copper sulfate electrodes? Speed vs. Durability Explained

- How should a copper sulfate reference electrode be stored? A Guide to Short-Term & Long-Term Storage

- How should a copper sulfate reference electrode be maintained? Ensure Accurate Electrochemical Measurements

- What is the operating principle of a copper sulfate reference electrode? Reliable Potential Measurement Explained