In metallurgy, the primary benefit of tempering is the significant increase in a material's toughness. After a metal like steel is hardened, it becomes extremely brittle and prone to shattering. Tempering is a subsequent heat treatment process that reduces this brittleness, making the final product more durable and resistant to fracture under impact or stress.

While the hardening process gives steel its strength and wear resistance, it comes at the cost of extreme brittleness. Tempering is the essential corrective step that intentionally sacrifices a small amount of hardness to gain a crucial amount of toughness, preventing catastrophic failure in real-world use.

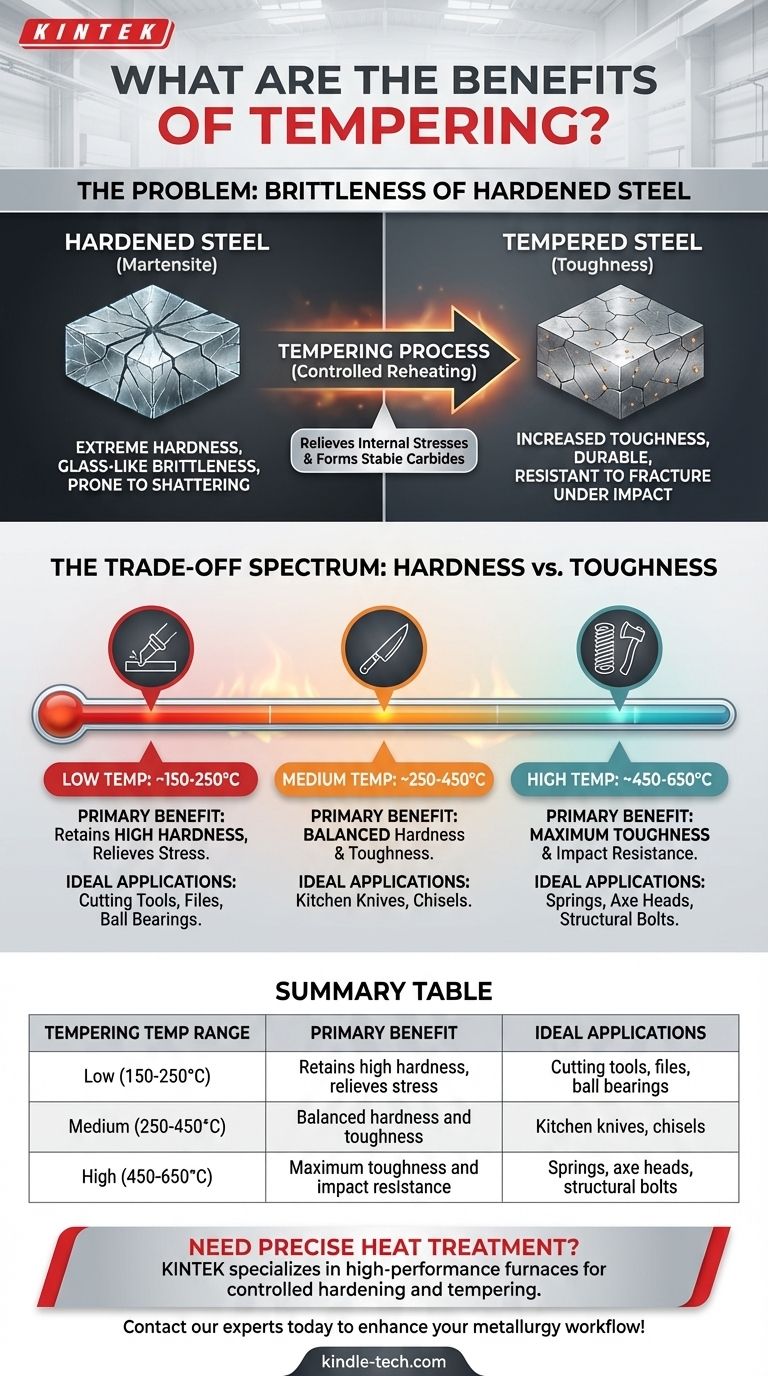

The Problem: The Brittleness of Hardened Steel

To understand the benefits of tempering, you must first understand the state of steel immediately after it is hardened.

What Happens During Hardening?

Hardening, or quenching, involves heating steel to a very high temperature and then cooling it with extreme speed, often by plunging it into water, oil, or brine.

This rapid cooling traps the material's atomic structure in a highly stressed, disorganized state known as martensite.

The Dangers of Untempered Martensite

Martensite is incredibly hard, but it is also incredibly brittle. The internal stresses are so high that the material behaves more like glass than metal.

An untempered, hardened steel component—like a knife blade or a gear—is practically useless. It would chip, crack, or even shatter under the slightest impact or load. It lacks toughness, which is the ability to absorb energy and deform without fracturing.

How Tempering Solves the Problem

Tempering is a controlled heating process that directly counteracts the negative side effects of hardening.

The Tempering Process Explained

The hardened steel part is reheated to a precise temperature, always below the critical point used for the initial hardening. It is held at this temperature for a specific duration to allow the internal structure to change.

Finally, the part is cooled, typically in still air. The rate of cooling from the tempering temperature is not as critical as it is during quenching.

Microstructural Changes

The applied heat provides the energy needed to relieve the high internal stresses created during quenching.

This allows the trapped carbon atoms to move and precipitate out of the martensite, forming tiny, finely dispersed carbide structures. This new, modified microstructure is much more stable and less stressed.

The Result: A Balance of Properties

By relieving these internal stresses, tempering dramatically increases the steel's toughness and ductility. The material is now far less likely to fracture.

While there is a corresponding decrease in hardness and strength, this trade-off is the entire point of the process. The goal is not maximum hardness, but an optimal balance of properties for a specific application.

Understanding the Trade-offs: Hardness vs. Toughness

The key variable in tempering is the temperature. By precisely controlling the tempering temperature, a metallurgist can dial in the exact properties required for the component.

The Tempering Spectrum

Lower tempering temperatures result in a small loss of hardness but a major gain in toughness. Higher temperatures result in a greater loss of hardness but a massive increase in toughness.

Low-Temperature Tempering (Approx. 150-250°C / 300-480°F)

This range is used when retaining maximum hardness and wear resistance is the priority. It relieves the most severe internal stresses without significantly softening the steel.

This is ideal for cutting tools, files, and ball bearings, where edge retention and surface hardness are paramount.

High-Temperature Tempering (Approx. 450-650°C / 840-1200°F)

This range is used when toughness, ductility, and impact resistance are the most important factors. The significant reduction in hardness is an acceptable trade-off for creating a highly durable part.

This is necessary for components like springs, structural bolts, axe heads, and hammers that must withstand repeated stress and high-impact forces.

Matching the Temper to the Application

Ultimately, the benefits of tempering are realized by selecting the correct temperature for the job.

- If your primary focus is maximum hardness and wear resistance (e.g., files, razor blades): A low-temperature temper is required to relieve stress without significantly sacrificing hardness.

- If your primary focus is a balanced performance (e.g., kitchen knives, chisels): A medium-temperature temper provides an ideal mix of hardness for edge retention and toughness to prevent chipping.

- If your primary focus is maximum toughness and impact resistance (e.g., springs, axe heads): A high-temperature temper is essential to ensure the material can absorb energy without fracturing.

Tempering transforms a brittle and unusable material into a reliable component by precisely tuning its properties to meet the demands of its function.

Summary Table:

| Tempering Temperature Range | Primary Benefit | Ideal Applications |

|---|---|---|

| Low (150-250°C / 300-480°F) | Retains high hardness, relieves stress | Cutting tools, files, ball bearings |

| Medium (250-450°C / 480-840°F) | Balanced hardness and toughness | Kitchen knives, chisels |

| High (450-650°C / 840-1200°F) | Maximum toughness and impact resistance | Springs, axe heads, structural bolts |

Need precise heat treatment for your metal components? KINTEK specializes in high-performance lab furnaces and equipment for controlled hardening and tempering processes. Whether you're developing tools, springs, or custom parts, our solutions deliver the exact balance of hardness and toughness your application demands. Contact our experts today to discuss how we can enhance your metallurgy workflow!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?