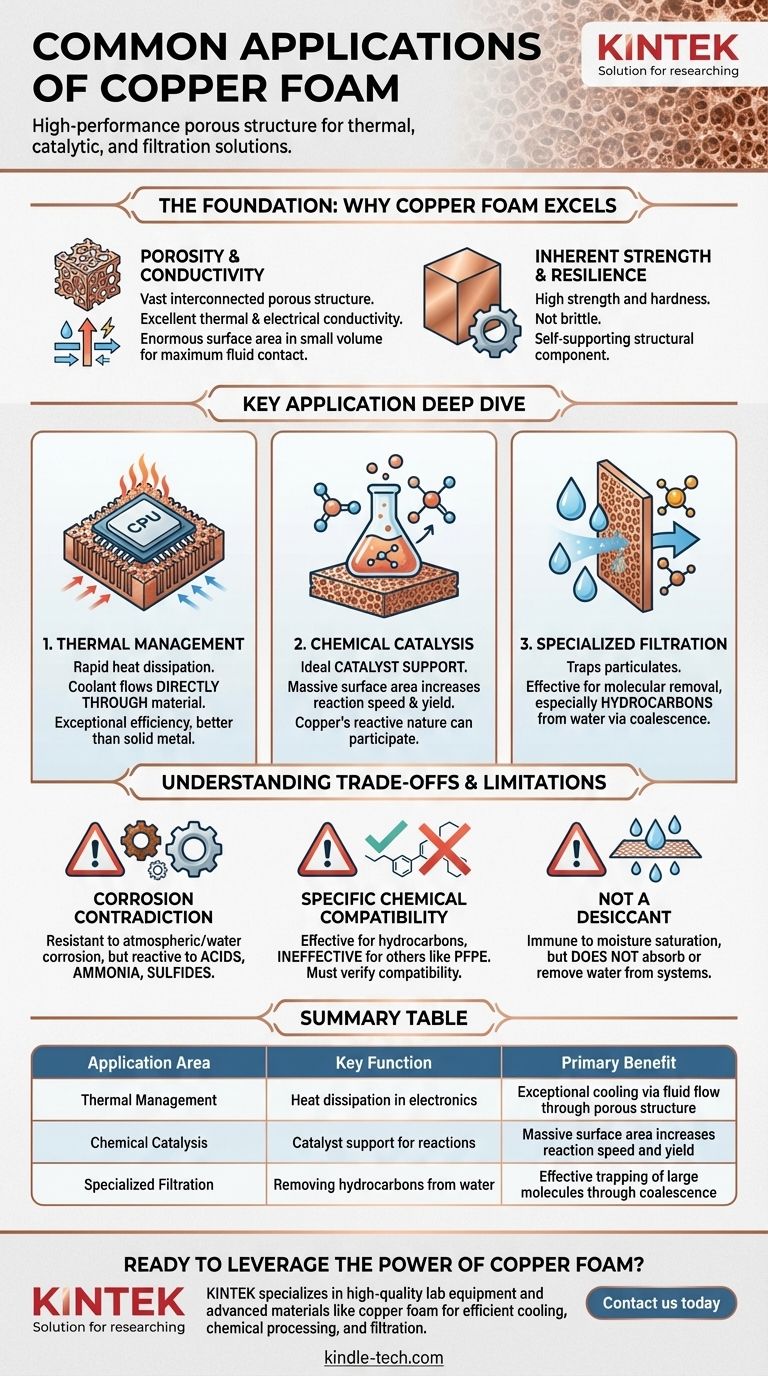

At its core, copper foam is a high-performance material valued for its unique combination of a porous, high-surface-area structure and copper's intrinsic properties. Its most common applications are in advanced thermal management for electronics, as a substrate for chemical catalysis, and in specialized filtration systems like wastewater treatment.

The true value of copper foam isn't just that it's made of copper; it's how its three-dimensional, open-cell structure unlocks new efficiencies for transferring heat and facilitating chemical reactions on a massive surface area.

The Foundation: Why Copper Foam Excels

To understand its applications, you must first understand its fundamental properties. The material's utility is not based on a single characteristic but on the powerful interplay between its structure and the nature of copper itself.

A Tale of Two Properties: Porosity and Conductivity

The primary advantage of copper foam is its combination of a vast, interconnected porous structure with copper's excellent thermal and electrical conductivity.

This structure creates an enormous surface area within a small volume, allowing for maximum contact with fluids like air or liquids.

Inherent Strength and Resilience

Unlike other porous materials that can be brittle, copper foam possesses high strength and hardness.

This allows it to be used not just as a passive medium but as a self-supporting structural component in demanding environments.

Key Application Deep Dive

The unique properties of copper foam make it a superior choice in several distinct technical fields. Each application leverages a different aspect of the material's core strengths.

Heat Dissipation and Thermal Management

This is arguably the most common application. The foam's high thermal conductivity rapidly pulls heat away from a source, like a CPU.

The open-cell structure then allows air or a liquid coolant to flow directly through the material, dissipating the heat with exceptional efficiency far beyond what a solid metal block could achieve.

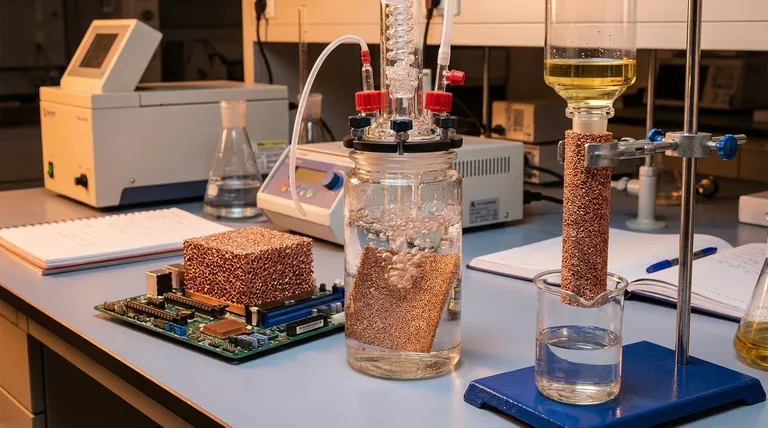

Chemical Catalysis and Reaction Support

In chemical engineering, reaction speed is often dependent on the available surface area. Copper foam serves as an ideal catalyst support.

Its high surface area provides more sites for chemical reactions to occur, increasing the efficiency and yield of the process. Copper's own reactive nature can also play a direct role in certain catalytic cycles.

Filtration and Wastewater Treatment

The foam's porous network acts as a physical filter to trap particulates. More importantly, its chemical properties make it effective for specific types of molecular removal.

It is particularly well-suited for removing hydrocarbons from water by trapping large molecules through a process of coalescence.

Understanding the Trade-offs and Limitations

While powerful, copper foam is not a universal solution. An objective assessment requires understanding its operational limits and potential failure points.

The Corrosion Contradiction

References can seem contradictory, citing both "corrosion resistance" and that it "can corrode." Both are true in different contexts.

Copper has good resistance to atmospheric and water corrosion compared to iron, but it is still a reactive metal. It will corrode in the presence of certain chemicals, such as acids, ammonia, and sulfides.

Chemical Compatibility is Not Universal

The material's effectiveness in filtration is highly specific. It excels at removing hydrocarbons but is completely ineffective for others, like PFPE (perfluoropolyether).

Engineers must verify its compatibility with the specific chemistry of their application; it is not an all-purpose filter medium.

Not a Solution for Moisture Removal

While copper foam is "immune to moisture saturation"—meaning water can pass through it without degrading the structure—it does not absorb or remove water from a system. It is a flow-through material, not a desiccant.

Making the Right Choice for Your Goal

To determine if copper foam is the correct material, align your primary engineering goal with its core strengths.

- If your primary focus is thermal management: Copper foam is an elite choice for creating compact, high-performance heat sinks and exchangers where fluid can flow directly through the dissipating element.

- If your primary focus is chemical processing: Use it as a robust, high-surface-area support for catalysts, especially in reactions involving hydrocarbons or where copper itself can act as the catalyst.

- If your primary focus is specialized filtration: Confirm its chemical compatibility for your target substance, as it is a specialist tool for applications like hydrocarbon removal, not a general-purpose filter.

Ultimately, copper foam's value is realized when your project demands a material that merges structural integrity with exceptional thermal and reactive surface area.

Summary Table:

| Application Area | Key Function | Primary Benefit |

|---|---|---|

| Thermal Management | Heat dissipation in electronics | Exceptional cooling via fluid flow through porous structure |

| Chemical Catalysis | Catalyst support for reactions | Massive surface area increases reaction speed and yield |

| Specialized Filtration | Removing hydrocarbons from water | Effective trapping of large molecules through coalescence |

Ready to leverage the power of copper foam in your lab?

KINTEK specializes in providing high-quality lab equipment and consumables, including advanced materials like copper foam, to meet the demanding needs of modern laboratories. Whether you are developing more efficient cooling systems, optimizing chemical processes, or designing specialized filtration, our expertise and products can help you achieve superior results.

Contact us today to discuss how our solutions can enhance your research and development projects.

Visual Guide

Related Products

- Copper Foam

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Evaporation Boat for Organic Matter

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What are the available sizes and thicknesses for copper foam? Optimize Your Thermal and Filtration Performance

- What are the proper storage conditions for nickel and copper foam? A Guide to Preserving Performance

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols

- What is copper foam used for? A Guide to Its High-Performance Thermal and Energy Applications

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage