At its core, a hydraulic machine is a system for transmitting and multiplying force. It achieves this using a set of five primary components: a reservoir to hold the fluid, a pump to create flow, valves to direct and control that flow, an actuator (like a cylinder or motor) to perform the work, and the hydraulic fluid itself, which acts as the medium for power transmission.

The essential principle to grasp is that these are not just individual parts, but components of an integrated circuit. This system is designed to convert electrical or mechanical power into hydraulic power, and then back into mechanical work with immense force multiplication.

The Core Components of a Hydraulic System

Understanding how hydraulic power is generated, controlled, and applied requires looking at each component's specific role in the fluid's journey. The system is a closed loop, where each part builds upon the last.

The Reservoir (The Starting Point)

A hydraulic reservoir is more than just a storage tank for the hydraulic fluid.

Its primary function is to hold a sufficient volume of fluid to supply the system's needs. It also plays a crucial role in dissipating heat from the fluid and allowing contaminants like dirt or water to settle out.

The Pump (The Heart of the System)

The pump converts mechanical energy (from an engine or electric motor) into hydraulic energy.

It does this by moving the hydraulic fluid, creating flow. A common misconception is that pumps create pressure; in reality, pressure is created by resistance to the fluid's flow, such as the load on an actuator. Common types include gear, vane, and piston pumps.

Valves (The Control System)

Valves are the "brains" of the hydraulic circuit, managing the fluid's direction, pressure, and flow rate.

Directional control valves determine the path the fluid takes, for instance, extending or retracting a cylinder. Pressure control valves (like relief valves) act as safety features, preventing over-pressurization. Flow control valves manage the speed of the actuators.

The Actuator (The Workhorse)

The actuator is where the hydraulic energy is converted back into useful mechanical work.

There are two primary types. A hydraulic cylinder converts the energy into linear motion and force (pushing or pulling). A hydraulic motor converts it into rotary motion and torque (spinning).

Hydraulic Fluid (The Lifeblood)

The fluid is an active component, not just a passive medium. Its primary job is to transmit power efficiently because it is virtually incompressible.

Beyond that, it also lubricates moving parts like the pump and actuators, helps seal clearances between components, and carries heat away from working areas back to the reservoir.

Supporting Components (The Connective Tissue)

Filters, hoses, tubes, and seals are essential for the system's integrity and longevity. Filters remove contaminants, while hoses and tubes transport the fluid under high pressure. Seals prevent leaks and keep dirt out.

Understanding the Trade-offs and Failure Points

A hydraulic system's power is also its primary vulnerability. The high pressures and tight tolerances mean that small issues can quickly lead to major failures if the core principles are ignored.

Contamination is the Enemy

The vast majority of hydraulic system failures are caused by fluid contamination. Dirt, metal particles, and water can score surfaces, clog valves, and cause pumps to fail catastrophically.

Proper filtration and fluid handling are not optional maintenance items; they are central to the system's operational life.

Heat Degrades Performance

As hydraulic fluid does its work, it generates heat. Excessive heat breaks down the fluid's chemical properties, reducing its ability to lubricate and causing it to form sludge and varnish.

This heat also damages seals, leading to leaks. The reservoir and dedicated coolers (if present) are critical for managing the system's thermal load.

Pressure Does Not Equal Flow

It is critical to distinguish between pressure and flow when troubleshooting. A pump produces flow; the load creates pressure.

A slow-moving actuator is a flow problem (e.g., a worn-out pump). An actuator that cannot move its intended load is a pressure problem (e.g., a faulty pressure relief valve or a load that exceeds system design).

Making the Right Choice for Your Goal

Understanding these components allows you to diagnose issues and appreciate the design intent of any hydraulic machine.

- If your primary focus is power and speed: The size and displacement of the pump and actuators are the most critical factors.

- If your primary focus is longevity and reliability: Your attention must be on fluid cleanliness, filtration, and temperature management.

- If your primary focus is precision and control: The sophistication and quality of the valving system are paramount.

By viewing these parts as an interconnected system, you gain true insight into the machine's operation, maintenance, and capabilities.

Summary Table:

| Component | Primary Function | Key Insight |

|---|---|---|

| Reservoir | Stores fluid, dissipates heat, settles contaminants | More than just a tank; critical for system health. |

| Pump | Converts mechanical energy into fluid flow (the heart) | Creates flow, not pressure. Pressure is created by resistance. |

| Valves | Controls direction, pressure, and flow rate (the brains) | Manages the entire system's operation and safety. |

| Actuator | Converts hydraulic energy into mechanical work (cylinder/motor) | The component that performs the actual pushing, pulling, or spinning. |

| Hydraulic Fluid | Transmits power, lubricates, seals, and cools | The lifeblood of the system; an active component, not passive. |

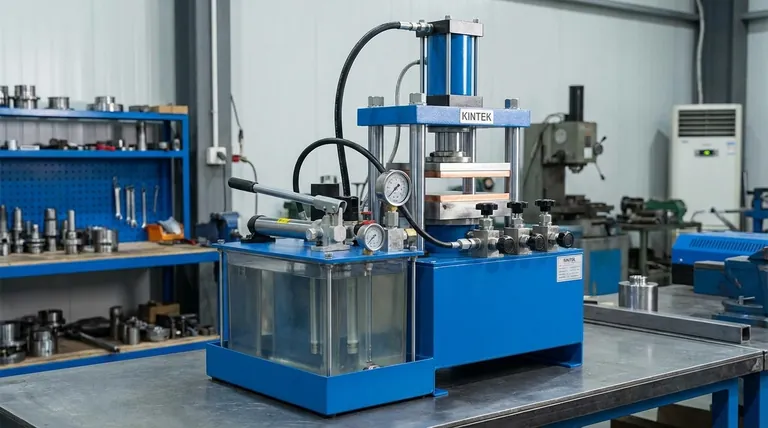

Need a reliable hydraulic system for your lab or industrial application?

At KINTEK, we understand that the precision and reliability of your equipment are paramount. Whether you're operating a lab press, a hydraulic clamp, or any machinery requiring controlled, high-force movement, the quality of the hydraulic components is critical to your success.

Our expertise in lab equipment and consumables means we can provide or help you source the right components to ensure your system operates efficiently and lasts longer. Let us help you achieve superior performance and minimize downtime.

Contact our experts today to discuss your specific hydraulic needs!

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Variable Speed Peristaltic Pump

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What is a hydraulic hot press? Unlock the Power of Heat and Pressure for Advanced Materials