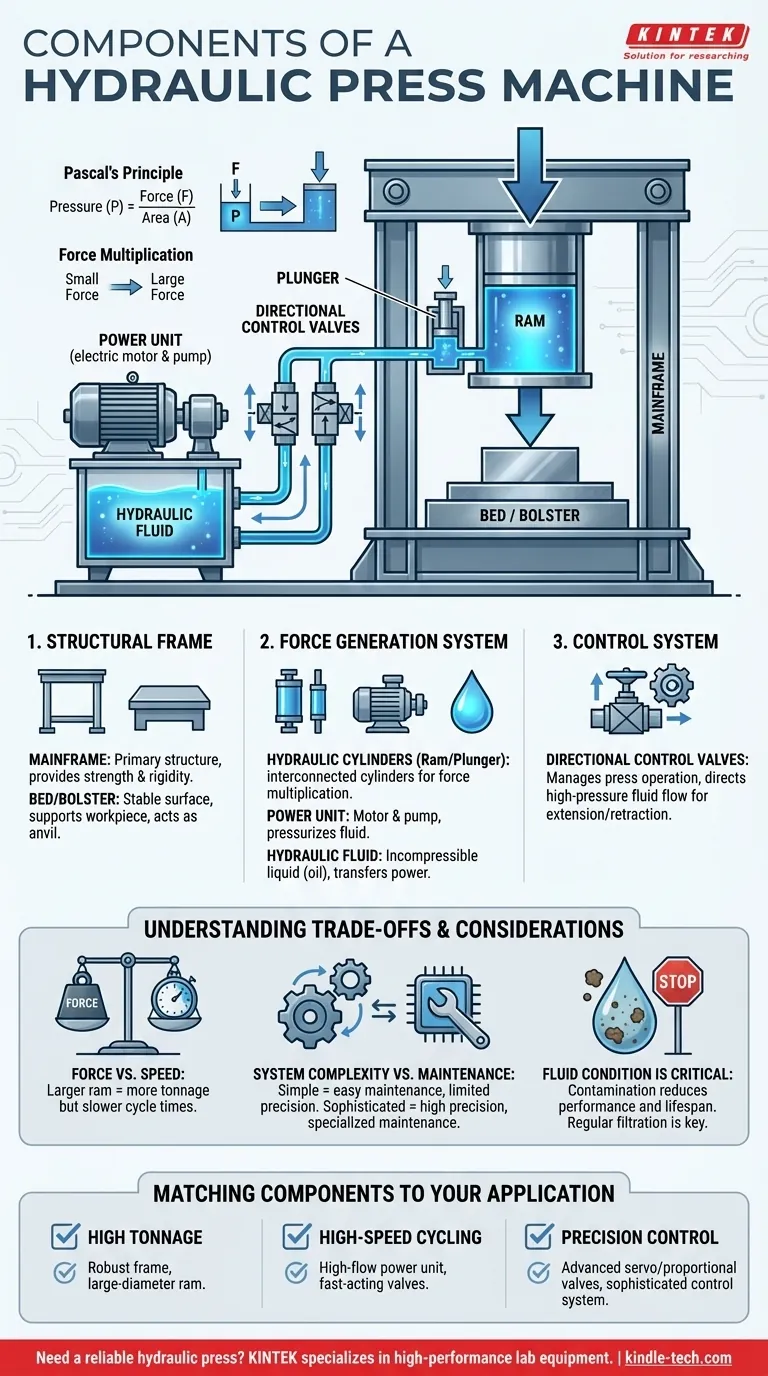

At its core, a hydraulic press machine consists of a mainframe, a power system, and a hydraulic control system. These three groups of components work in concert, using pressurized, incompressible fluid to generate immense mechanical force according to Pascal's principle.

The fundamental design of a hydraulic press uses a power unit to pressurize fluid, which is then directed by control valves into a hydraulic cylinder. The size difference between the input (plunger) and output (ram) cylinders is what multiplies the initial force, creating the press's power.

The Core Structural Components

The structure of the press provides the foundation and resistance necessary for the hydraulic system to perform work. It is the machine's skeleton.

The Mainframe

The mainframe is the primary structure that holds all other components together. Its strength and rigidity are critical, as it must withstand the massive forces generated by the hydraulic system without deforming.

The Bed or Bolster

The bed (also called a bolster or table) is the flat, stable surface that supports the material or workpiece being pressed. It is mounted to the mainframe and serves as the anvil against which the ram applies force.

The Force Generation System

This is the heart of the machine, responsible for creating, multiplying, and applying the force. It's where the hydraulic principles are put into action.

Hydraulic Cylinders (Ram and Plunger)

A hydraulic press utilizes a system of interconnected cylinders. The smaller cylinder is often called the plunger, where the initial force is applied to the fluid.

This pressurized fluid then acts on the much larger cylinder, known as the ram. Because the pressure is equal throughout the fluid, the larger surface area of the ram multiplies the initial force significantly.

The Power Unit

The power unit is the muscle of the press. It typically consists of an electric motor connected to a hydraulic pump. The pump draws hydraulic fluid from a reservoir and pressurizes it, providing the flow needed to actuate the cylinders.

Hydraulic Fluid

This is the incompressible liquid (usually a specialized oil) that transfers power through the system. Its primary job is to transmit pressure from the pump to the ram cylinder without losing volume.

The Control System

The control system acts as the brain, directing the power generated by the hydraulic system to perform precise work.

Directional Control Valves

Control valves are crucial for managing the operation of the press. They direct the flow of high-pressure hydraulic fluid to either extend or retract the ram, allowing the operator to control the machine's movement precisely.

Understanding the Trade-offs

Simply knowing the components is not enough; understanding their interplay and inherent limitations is key to effective operation.

Force vs. Speed

There is an inherent trade-off between the force a press can generate and the speed at which it operates. A larger ram creates more tonnage but requires a greater volume of fluid to move, often resulting in slower cycle times unless paired with a very high-output power unit.

System Complexity and Maintenance

A simple press with basic manual controls is easy to maintain but offers limited precision. Conversely, a press with sophisticated proportional valves and electronic controls offers high precision but requires more specialized maintenance and troubleshooting.

Fluid Condition is Critical

The hydraulic fluid is the lifeblood of the system. Contamination with dirt or water can cause premature wear on pumps, clog valves, and lead to seal failure, drastically reducing the machine's performance and lifespan. Regular filtration and fluid analysis are non-negotiable.

Matching Components to Your Application

The specific configuration of these components determines the press's capabilities. Consider your primary goal when evaluating a machine.

- If your primary focus is high tonnage: You need a machine with an exceptionally robust frame and a large-diameter ram cylinder.

- If your primary focus is high-speed cycling: You should prioritize a system with a high-flow hydraulic power unit and fast-acting directional control valves.

- If your primary focus is precision control: Look for a press equipped with advanced servo or proportional valves and a sophisticated control system for fine-tuning force, speed, and position.

By understanding how these core components function and interact, you can more effectively operate, maintain, and select the right hydraulic press for any task.

Summary Table:

| Component Group | Key Parts | Primary Function |

|---|---|---|

| Structural Frame | Mainframe, Bed/Bolster | Provides foundation and withstands force |

| Force Generation | Hydraulic Cylinders (Ram/Plunger), Power Unit, Hydraulic Fluid | Generates and multiplies mechanical force |

| Control System | Directional Control Valves | Directs fluid flow for precise operation |

Need a reliable hydraulic press for your lab or production line? KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision, durability, and efficiency. Whether you require high tonnage, fast cycling, or exact control, our solutions are tailored to meet your specific needs. Contact us today to discuss how our equipment can enhance your operations!

Visual Guide

Related Products

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab