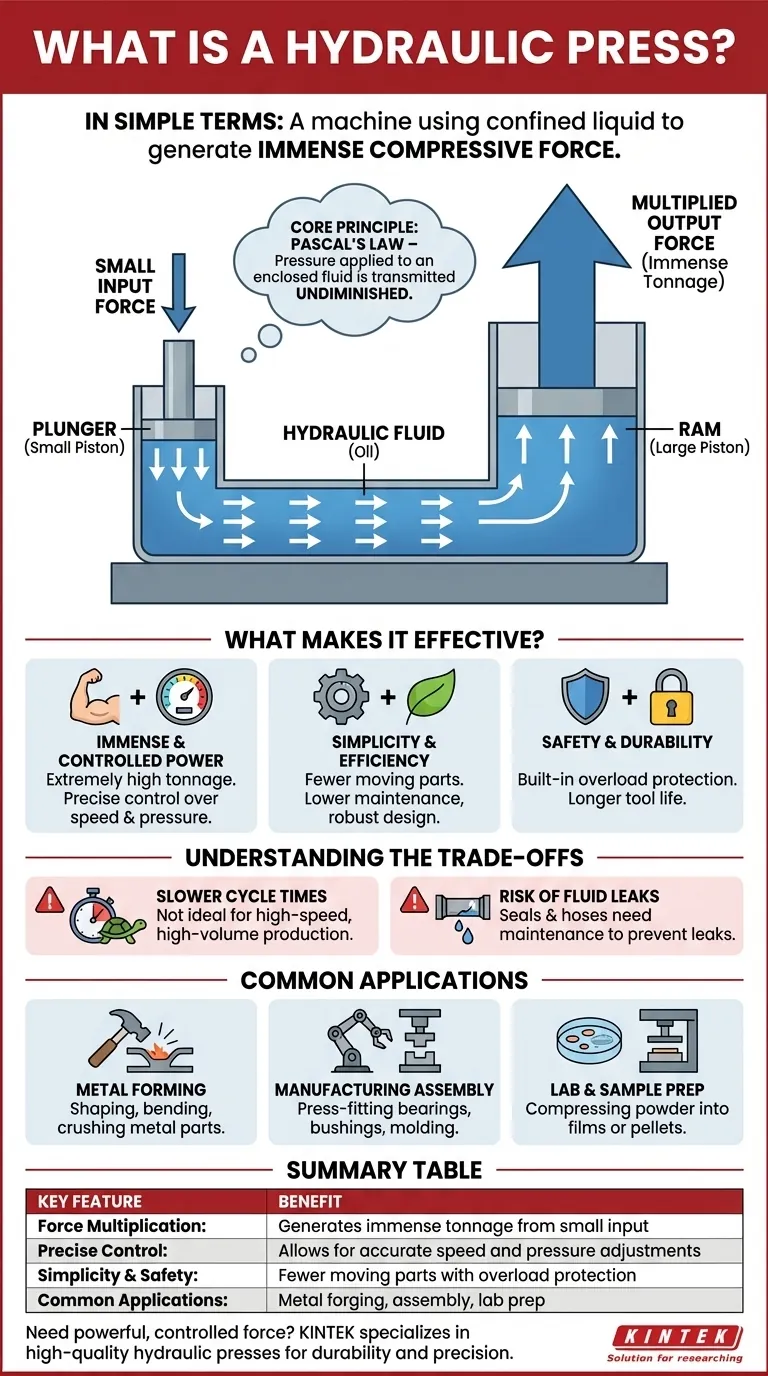

In simple terms, a hydraulic press is a machine that uses a confined liquid to generate an immense compressive force. It works by applying a small amount of force to a small piston which, thanks to the incompressibility of the liquid, translates into a much larger and more powerful force on a bigger piston. This principle allows it to easily shape, bend, or crush strong materials like metal with relatively little initial effort.

The power of a hydraulic press comes from a simple physics principle: Pascal's Law. By pushing on a small amount of trapped fluid, you create pressure that is transmitted equally throughout, allowing a large piston to exert a massive, controlled force with minimal input.

The Core Principle: How Force is Multiplied

At the heart of every hydraulic press is a fundamental law of fluid mechanics. Understanding this principle is key to understanding the machine's power and utility.

Pascal's Law in Action

A hydraulic press operates based on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In practical terms, this means pressure is distributed evenly everywhere within the system.

The Two-Piston System

The machine consists of two interconnected cylinders of different sizes, each with a piston and filled with a hydraulic fluid (typically oil).

The smaller cylinder is known as the plunger, where the initial, smaller force is applied. The larger cylinder is the ram, which delivers the final, multiplied output force.

Because the pressure is the same on both pistons, the force on the larger piston (the ram) is magnified in direct proportion to its larger surface area. This is how a small push on the plunger can lift or crush with tons of force at the ram.

What Makes a Hydraulic Press So Effective?

The simple design of a hydraulic press provides several significant advantages over more complex mechanical systems, making it a preferred tool in many industries.

Immense and Controlled Power

The primary benefit is the ability to generate extremely high tonnage (compressive force).

Operators also have precise control over the speed and pressure of the ram's movement, allowing for the creation of unique and complex shapes that might be impossible with other methods.

Simplicity and Efficiency

Compared to mechanical presses, hydraulic systems have fewer moving parts, which reduces wear and tear and lowers maintenance costs.

They are often quieter, require less floor space for the force they generate, and have a simple, robust design.

Built-in Safety and Durability

Hydraulic systems have built-in overload protection. Once the maximum pressure is reached, the system will not exert any more force, preventing damage to the machine or the workpiece.

This inherent safety feature also contributes to a longer lifespan for the machine's tools and dies.

Understanding the Trade-offs

While incredibly powerful and versatile, hydraulic presses are not the perfect solution for every application. It's important to recognize their inherent limitations.

Potential for Slower Cycle Times

The movement of the hydraulic ram can be slower than the rapid stamping action of a purely mechanical press. This makes them less suitable for high-speed, high-volume production lines where cycle time is the most critical factor.

The Risk of Fluid Leaks

Any system that relies on high-pressure fluid is susceptible to leaks. Over time, seals and hoses can degrade, requiring regular maintenance to prevent fluid loss, ensure consistent pressure, and maintain a clean working environment.

Common Applications

The unique combination of force, control, and simplicity makes the hydraulic press a vital tool across various fields.

Metal Forming and Forging

This is a primary use, where the press manipulates metal billets or ingots. It's used for shaping, straightening, and crushing metal parts in manufacturing and fabrication shops.

Manufacturing and Assembly

Hydraulic presses are used for assembly operations like press-fitting bearings or bushings, as well as for molding plastic, rubber, and other composite materials.

Laboratory and Sample Preparation

In scientific and quality control settings, smaller hydraulic presses are commonly used to compress powdered material into thin films or pellets for analysis.

Making the Right Choice for Your Goal

Understanding the core strengths of a hydraulic press helps clarify when it is the ideal tool for the job.

- If your primary focus is immense, controlled force: A hydraulic press is superior for applications like forging thick metal or performing tasks that require tons of pressure applied slowly and precisely.

- If your primary focus is versatility: The control over speed and pressure makes the hydraulic press perfect for jobs with unique geometries or for workshops that handle a wide variety of tasks.

- If your primary focus is operational efficiency and safety: The simple design, built-in overload protection, and quieter operation make it a safe, reliable, and cost-effective choice for many workshops and labs.

Ultimately, the hydraulic press is a testament to how a fundamental law of physics can be harnessed to create an extraordinary and highly practical mechanical advantage.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Force Multiplication | Generates immense tonnage from a small input force |

| Precise Control | Allows for accurate speed and pressure adjustments |

| Simplicity & Safety | Fewer moving parts with built-in overload protection |

| Common Applications | Metal forging, manufacturing assembly, lab sample prep |

Need powerful, controlled force for your lab or workshop? KINTEK specializes in high-quality hydraulic presses and lab equipment designed for durability, precision, and safety. Whether you're shaping metal, preparing samples, or assembling components, our solutions deliver the reliable performance you need. Contact us today to find the perfect hydraulic press for your specific application!

Visual Guide

Related Products

- Manual Lab Heat Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are maintenance requirements for the hydraulic systems? Proactive Strategies for Maximum Uptime

- What is the core function of a laboratory hydraulic press in the production of fuel cell bipolar plates? Expert Guide

- What is the importance of using a laboratory hydraulic press for R1/3Zr2(PO4)3 samples? Enhance Ion Conductivity

- What role does mechanical pressing play in recycled graphite electrodes? Optimize Density and Performance

- What makes a hydraulic press so powerful? Unlocking the Physics of Force Multiplication

- What PPE is required for hydraulic press? Essential Safety Gear for High-Force Operations

- How do you prepare XRF samples? Master the Two Key Methods for Accurate Results

- How is a laboratory hydraulic press utilized for nanoporous material precursors? Optimize Density & Uniformity