In short, a manual press is a machine that uses human force to accomplish a task, typically either compacting/shaping a material or separating solids from a liquid. The term is broad and most commonly refers to one of two distinct devices: a manual hydraulic press, which generates high force for tasks like sample preparation, or a manual filter press, which separates materials by squeezing a liquid out of a slurry.

The term "manual press" is ambiguous and describes two fundamentally different tools. One uses hydraulic fluid to compact materials with great force, while the other uses mechanical pressure to filter liquids from solids. Your specific goal—either compaction or separation—will determine which type of manual press is relevant to you.

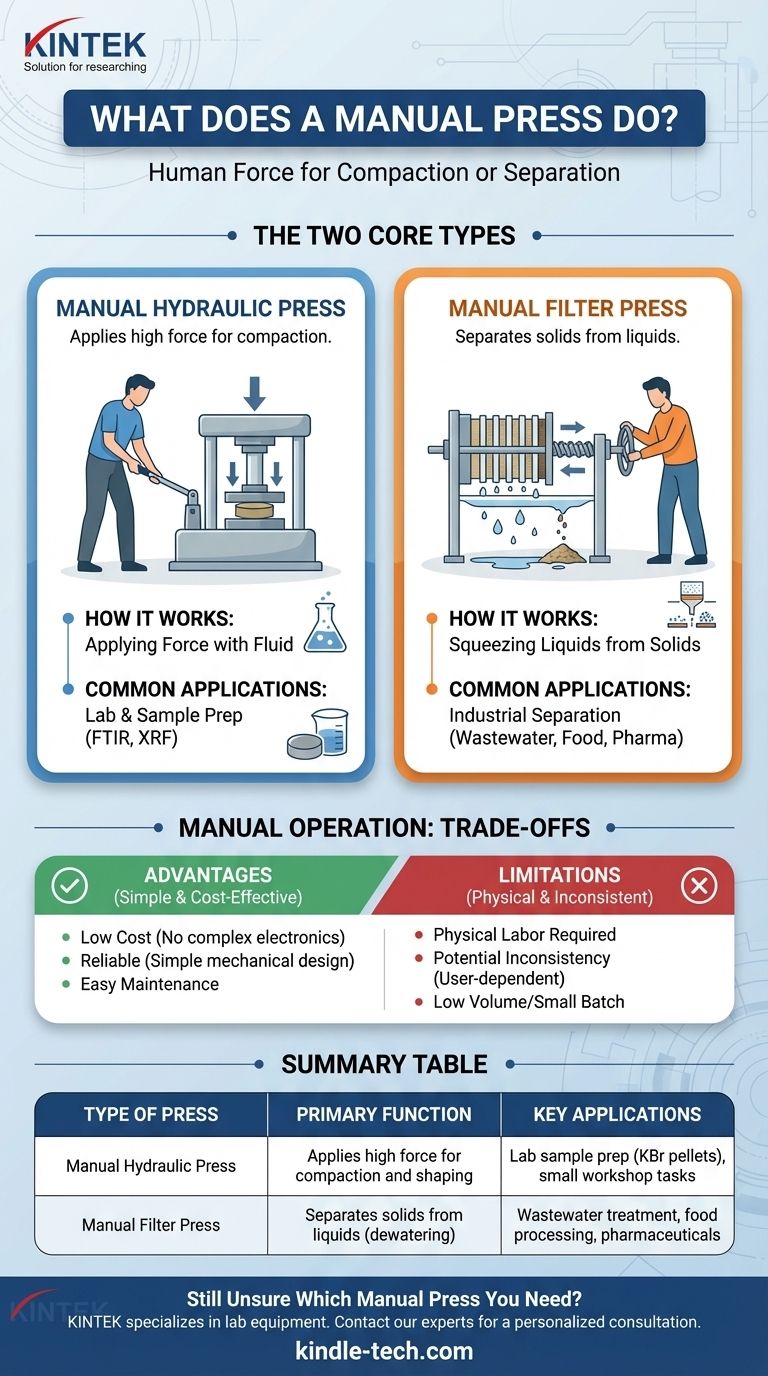

The Two Core Types of Manual Presses

The critical distinction is not the manual operation but the task the press is designed to perform. Understanding this difference is essential to understanding their function and application.

Type 1: The Manual Hydraulic Press

A manual hydraulic press is a tool for applying significant, concentrated force to a small area. It operates on the principle of fluid dynamics to multiply the user's effort.

How It Works: Applying Force with Fluid

A manual hydraulic press consists of a cylinder filled with hydraulic oil and a piston. The operator uses a hand-operated lever or pump to build pressure within the oil. This pressure acts on the piston, causing it to move and exert a powerful compressive force on any material placed on its platform.

This mechanism is ideal for generating tons of force with relatively little physical effort, making it perfect for lab and small workshop tasks.

Common Applications: Lab and Workshop Tasks

These presses are most frequently found in laboratories and small-scale fabrication environments. Their primary function is for sample preparation for analytical techniques like FTIR spectroscopy (making KBr pellets) and XRF (X-ray fluorescence), where powdered material must be compressed into a solid, uniform disc.

Type 2: The Manual Filter Press

A manual filter press is not designed for compaction but for solid-liquid separation. Its goal is to remove as much liquid as possible from a solid-liquid mixture, or slurry.

How It Works: Squeezing Liquids from Solids

This press uses a series of plates covered in a filter cloth. Slurry is pumped into the chambers between these plates. A large, hand-cranked screw jack then applies mechanical pressure, squeezing the plates together.

The pressure forces the liquid (filtrate) to pass through the filter cloth, leaving the solid particles behind as a compressed "filter cake."

Common Applications: Industrial Separation

The manual filter press is a workhorse in various industries for dewatering. Common applications include wastewater treatment, food processing, pharmaceuticals, metallurgy, and the chemical industry. It is highly effective for any process that requires separating solids from a liquid efficiently.

Understanding the Trade-offs of "Manual" Operation

Choosing a manual press over an automated or powered version involves a clear set of trade-offs focused on simplicity, cost, and scale.

The Primary Advantage: Simplicity and Cost

Manual presses have no complex electronic components, wiring, or power requirements. This makes them significantly less expensive to purchase and operate, with a near-zero running cost. Their simple mechanical design—either a hydraulic pump or a screw jack—makes them incredibly reliable and easy to maintain and repair.

The Main Limitation: Physical Effort and Inconsistency

The most obvious downside is the requirement for physical labor. For a hydraulic press, this can also lead to inconsistent pressure application from one user to another, which may affect the repeatability of sensitive lab preparations. Furthermore, manual operation is only practical for low-volume or small-batch processes and does not scale to large industrial production.

Making the Right Choice for Your Goal

Selecting the correct press depends entirely on the job you need to accomplish.

- If your primary focus is compacting lab samples or forming small parts: You need a manual hydraulic press, which uses fluid pressure for high-force applications.

- If your primary focus is separating solids from a liquid slurry: You need a manual filter press, which is designed specifically for dewatering and filtration tasks.

- If your primary focus is cost-effectiveness and simplicity for low-volume work: A manual press is ideal, as it avoids the expense and complexity of automated systems.

Understanding this distinction empowers you to select the precise tool engineered for your specific task.

Summary Table:

| Type of Manual Press | Primary Function | Key Applications |

|---|---|---|

| Manual Hydraulic Press | Applies high force for compaction and shaping | Lab sample prep (KBr pellets for FTIR, XRF), small workshop tasks |

| Manual Filter Press | Separates solids from liquids (dewatering) | Wastewater treatment, food processing, pharmaceuticals, chemical industry |

Still Unsure Which Manual Press You Need?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Whether you're preparing samples for analysis or require reliable solid-liquid separation, our experts can help you select the right manual press for your specific application, ensuring cost-effectiveness and reliable performance.

Contact our team today for a personalized consultation and discover how the right press can enhance your workflow efficiency.

Visual Guide

Related Products

- Manual Lab Heat Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the efficiency of a hydraulic press? Harness Unmatched Force Multiplication for Your Lab

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What are the potential hazards in a hydraulic press? Understanding the Risks of Crushing, Injection, and Failure

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab