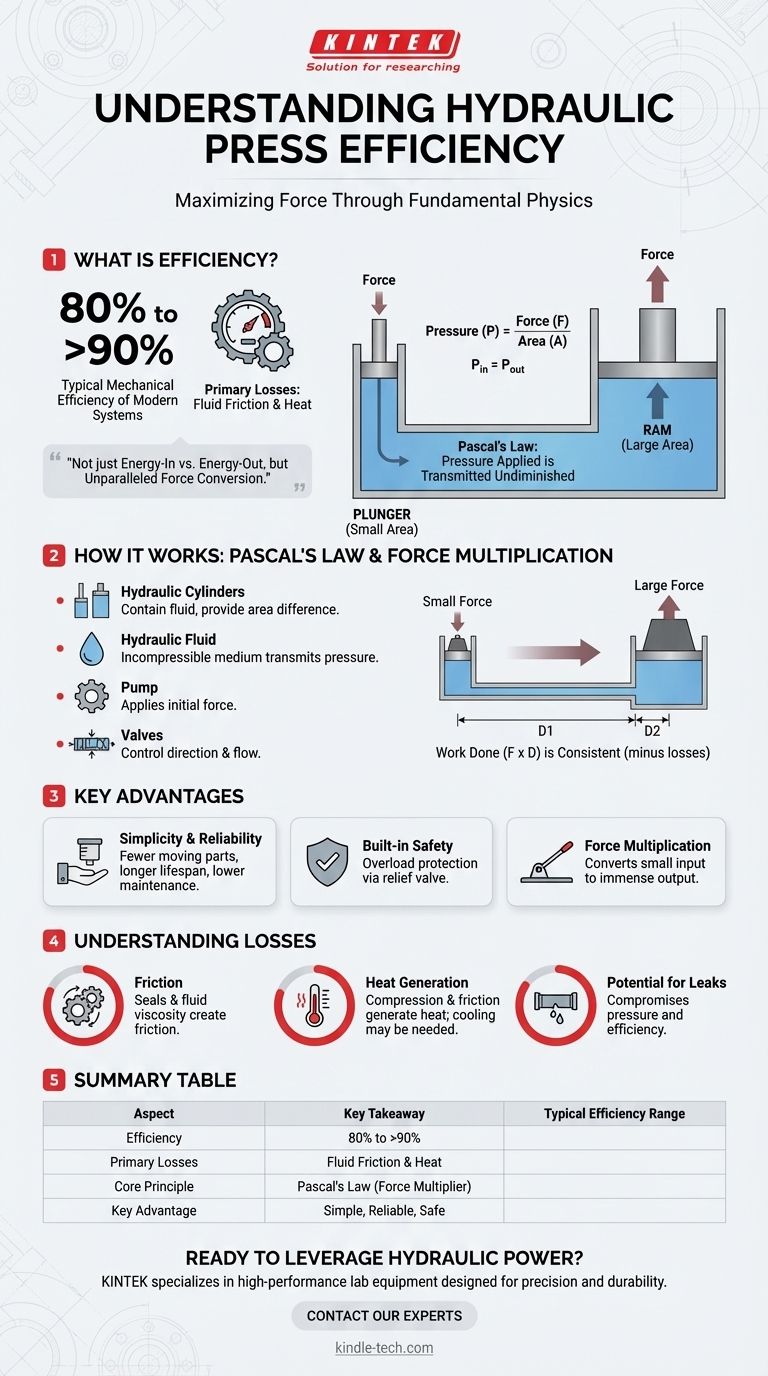

In purely mechanical terms, a hydraulic press is a highly efficient machine for multiplying force. While a single, universal efficiency number doesn't exist—as it depends on the specific design, size, and condition of the machine—modern hydraulic presses typically operate with an efficiency of 80% to over 90%, with the primary losses coming from fluid friction and heat.

The "efficiency" of a hydraulic press is best understood not as a simple energy-in versus energy-out calculation, but as its unparalleled ability to convert a small input force into an immense output force through the principles of fluid dynamics.

The Principle Behind Hydraulic Efficiency: Pascal's Law

The incredible force multiplication of a hydraulic press is governed by a fundamental principle of fluid mechanics known as Pascal's Law. This law states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

How a Small Force Becomes Immense Pressure

A hydraulic press is constructed with two interconnected cylinders of different sizes, filled with hydraulic fluid. One cylinder is small (the plunger), and the other is significantly larger (the ram).

When a small force is applied to the plunger, it creates pressure throughout the fluid. Because the area of the ram is much larger, that same pressure exerts a proportionally larger force on the ram. This is the simple but powerful secret to its operation.

The Role of Core Components

The system's effectiveness relies on a few key parts working in concert:

- Hydraulic Cylinders (Plunger and Ram): These contain the fluid and provide the different surface areas needed for force multiplication.

- Hydraulic Fluid: This is the medium that transmits the pressure. Its incompressibility is critical.

- Pump: This component, often part of a hydraulic power unit, applies the initial force to the fluid.

- Valves: These control the direction and flow of the fluid, allowing the ram to extend and retract with precision.

What "Efficiency" Really Means for a Hydraulic Press

Beyond a numerical percentage, the true efficiency of a hydraulic press is reflected in its design and operational advantages.

Force Multiplication, Not Energy Creation

It's crucial to understand that a hydraulic press does not create energy. It is a force multiplier. You apply a small force over a long distance on the plunger to get a large force over a short distance on the ram. The work done (Force x Distance) remains consistent, minus any frictional losses.

Simplicity and Reliability

As the references note, hydraulic presses have a simple design with fewer moving parts compared to mechanical presses. This structural simplicity leads to greater operational efficiency, with a longer lifespan for tools, lower maintenance requirements, and increased reliability.

Built-in Safety and Control

The nature of hydraulic fluid provides built-in overload protection. If the force exceeds the system's pressure limit, a relief valve can activate, preventing catastrophic failure. This makes the system inherently safe and robust.

Understanding the Trade-offs and Energy Losses

No machine is 100% efficient. Understanding where energy is lost helps provide a complete picture of the system's performance.

Friction from Seals and Fluids

The movement of the piston seals against the cylinder walls creates friction. Furthermore, the viscosity of the hydraulic fluid itself generates internal friction as it flows, especially through valves and pipes. This friction is converted into heat.

Heat Generation

The act of compressing a fluid and the friction within the system both generate heat. In high-use industrial systems, this heat represents the primary form of energy loss. Many large presses require cooling systems to dissipate this heat and maintain operational stability.

Potential for Leaks

The entire system relies on being perfectly sealed to maintain pressure. Any leak in a hose, fitting, or seal will cause a drop in pressure, directly compromising the press's efficiency and ability to generate force.

Making the Right Choice for Your Goal

Understanding these principles allows you to evaluate the efficiency of a hydraulic press based on your specific application.

- If your primary focus is generating massive, controllable force: The hydraulic press is exceptionally efficient due to its simple and powerful application of force multiplication.

- If your primary focus is low operational cost and reliability: The simple design with fewer moving parts makes it an efficient long-term choice that requires less maintenance than complex mechanical systems.

- If your primary focus is energy conservation: Be aware that while mechanically effective, significant energy can be lost as heat in high-cycle operations, making system cooling and maintenance key to preserving efficiency.

Ultimately, the true efficiency of a hydraulic press is found in its simple, powerful, and reliable application of fundamental physics.

Summary Table:

| Aspect of Efficiency | Key Takeaway |

|---|---|

| Typical Efficiency Range | 80% to over 90% for modern systems |

| Primary Losses | Fluid friction and heat generation |

| Core Principle | Pascal's Law (Force Multiplication) |

| Key Advantage | Simple design, reliability, and built-in safety |

Ready to leverage the power and efficiency of a hydraulic press in your lab? KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision and durability. Our solutions are tailored to meet the demanding needs of research and development laboratories, ensuring you get the reliable force multiplication required for your critical applications. Contact our experts today to find the perfect press for your workflow!

Visual Guide

Related Products

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What are the potential hazards in a hydraulic press? Understanding the Risks of Crushing, Injection, and Failure