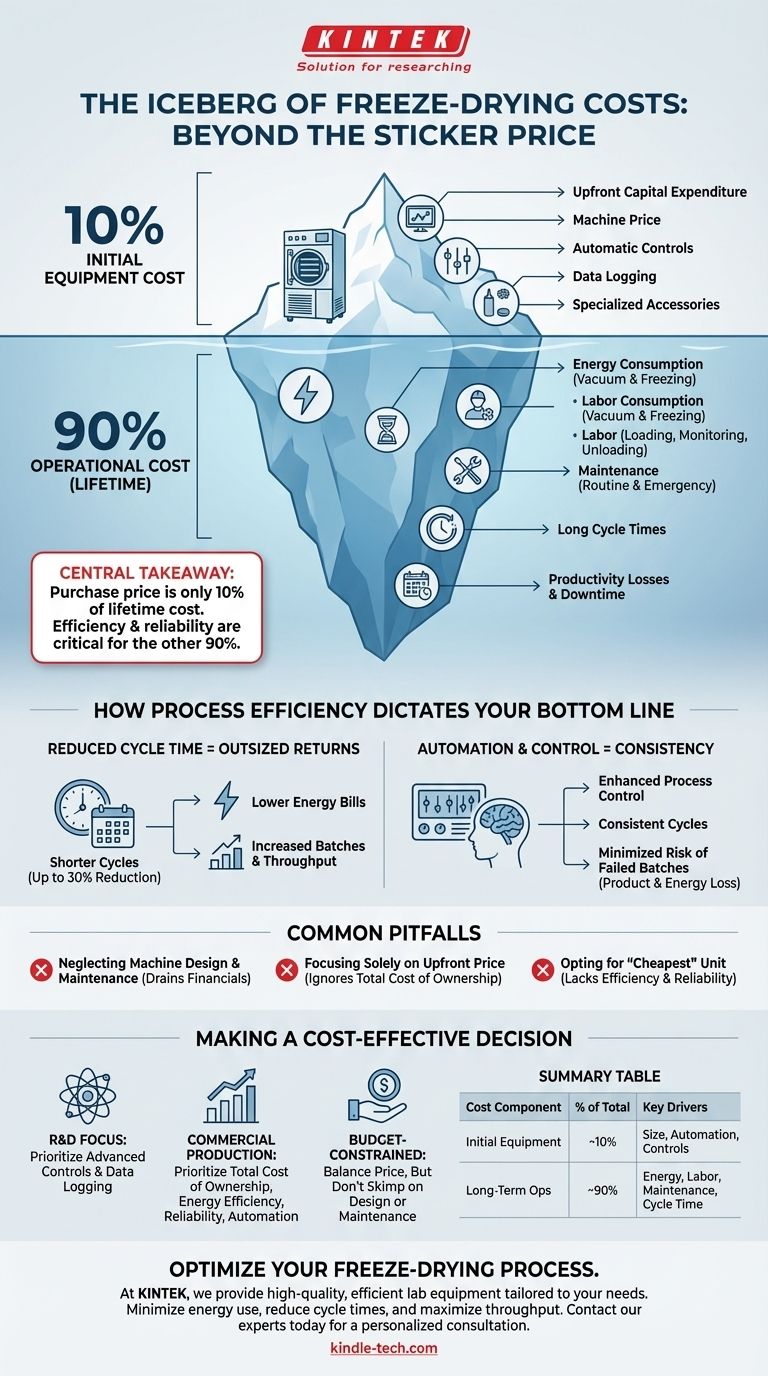

To understand the cost of freeze drying, you must look far beyond the initial purchase price of the equipment. While the machine itself is a significant investment, it represents only a small fraction of the total cost. The vast majority of expenses, approximately 90%, are tied to the long-term operation of the system.

The central takeaway is this: The purchase price of a freeze dryer is only 10% of its lifetime cost. The other 90% is consumed by operational expenses, making efficiency and reliability the most critical factors for managing your budget.

Deconstructing the 10/90 Cost Split

The most common mistake when evaluating freeze drying is focusing solely on the sticker price. A true cost analysis requires separating the one-time capital expenditure from the recurring, and much larger, operational expenditures.

The Initial Outlay: The 10% Equipment Cost

This is the upfront, visible cost of the freeze-drying unit. This price is not static and is influenced by several factors.

Features like automatic controls and data logging capabilities significantly increase the initial price. However, they also provide an opportunity to improve process control and reduce long-term operational costs.

The size, capacity, and inclusion of specialized accessories will also directly impact the purchase price.

The Hidden Giant: The 90% Operational Cost

This is the total cost of running and maintaining the machine over its lifespan. It is where your budget will either be protected or eroded.

Key drivers of operational cost include energy consumption, as the processes of freezing and creating a vacuum are energy-intensive. It also includes labor for loading, monitoring, and unloading, as well as routine and emergency maintenance.

Long cycle times increase energy and labor costs per batch, directly reducing your facility's overall throughput and profitability.

How Process Efficiency Dictates Your Bottom Line

Because operational costs dominate the financial picture, any improvement in process efficiency delivers an outsized return on investment. The goal is to minimize the cost per batch.

The Impact of Cycle Time

The duration of the freeze-drying cycle is a primary lever for cost control. A well-optimized process can reduce drying times by as much as 30%.

This reduction directly lowers energy bills and increases the number of batches you can run in a given period, fundamentally improving your cost structure.

The Role of Automation and Control

Investing in a machine with better controls is a trade-off between a higher upfront cost and lower long-term operational costs.

Enhanced process control leads to more consistent, repeatable, and efficient cycles. This minimizes the risk of a failed batch, which represents a total loss of product, time, and energy.

Understanding the Common Pitfalls

Many organizations overspend on freeze drying by falling into predictable traps. Recognizing them candidatos your first line of defense.

Neglecting Machine Design and Maintenance

A poorly designed or poorly maintained machine is a source of continuous financial drain. These issues lead to productivity losses, higher energy use, and unexpected downtime.

Opting for a machine based on price alone, without considering the quality of its design and the ease of maintenance, is a classic mistake that inflates the 90% operational cost.

Focusing Solely on Upfront Price

The "cheapest" machine is rarely the most cost-effective. A lower-priced unit may lack the efficiency, reliability, or control features CHCl reduce your total cost of ownership.

Always evaluate equipment based on its projected operational cost, not just its purchase price.

Making a Cost-Effective Decision

Your ideal approach depends on your primary objective. Match your purchasing criteria to your specific goal to ensure you are making a sound financial investment.

- If your primary focus is research and development: Prioritize systems with advanced controls and data logging to give you the deepest insight and control over your process.

- If your primary focus is commercial production: Prioritize total cost of ownership, focusing on energy efficiency, reliability, and automation to minimize long-term operational expenses.

- If your primary focus is a budget-constrained project: Seek a balance, but understand that skimping on a well-designed process or a solid maintenance plan will inevitably cost you more in the long run.

Ultimately, viewing freeze drying as a long-term operational investment, not just a one-time purchase, is the key to making a financially sound decision.

Summary Table:

| Cost Component | Percentage of Total Cost | Key Drivers |

|---|---|---|

| Initial Equipment Purchase | ~10% | Machine size, automation, controls, accessories |

| Long-Term Operational Costs | ~90% | Energy consumption, labor, maintenance, cycle time |

Ready to optimize your freeze-drying process and significantly reduce your long-term operational costs?

At KINTEK, we specialize in providing high-quality, efficient lab equipment and consumables tailored to your laboratory's specific needs. Our freeze-drying solutions are designed with reliability and process efficiency in mind, helping you minimize energy use, reduce cycle times, and maximize throughput.

Don't let hidden costs erode your budget. Contact our experts today for a personalized consultation to find the most cost-effective solution for your R&D or production goals!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- How does freeze drying extend the shelf life of pharmaceutical products? Preserve Potency and Stability for Years

- What properties are involved in evaporation? Master the Key Factors for Efficient Drying

- What property determines evaporation rate? Control heat, pressure, and surface area for optimal results.

- What physical property enhancements does freeze drying provide for pharmaceutical products? Achieve Superior Stability & Global Distribution

- What role do laboratory freeze dryers play in the food industry? Unlock Superior Food Preservation