The primary disadvantages of a vibro sifter are its susceptibility to screen blinding and breakage, its high maintenance requirements, and its operational limitations with certain types of materials. These machines can also generate significant noise and dust, creating environmental challenges in a production facility.

While highly effective for basic particle separation, a vibro sifter's core weakness is its reliance on pure mechanical vibration. This single mechanism creates inherent trade-offs in maintenance, material compatibility, and operational efficiency that you must understand before implementation.

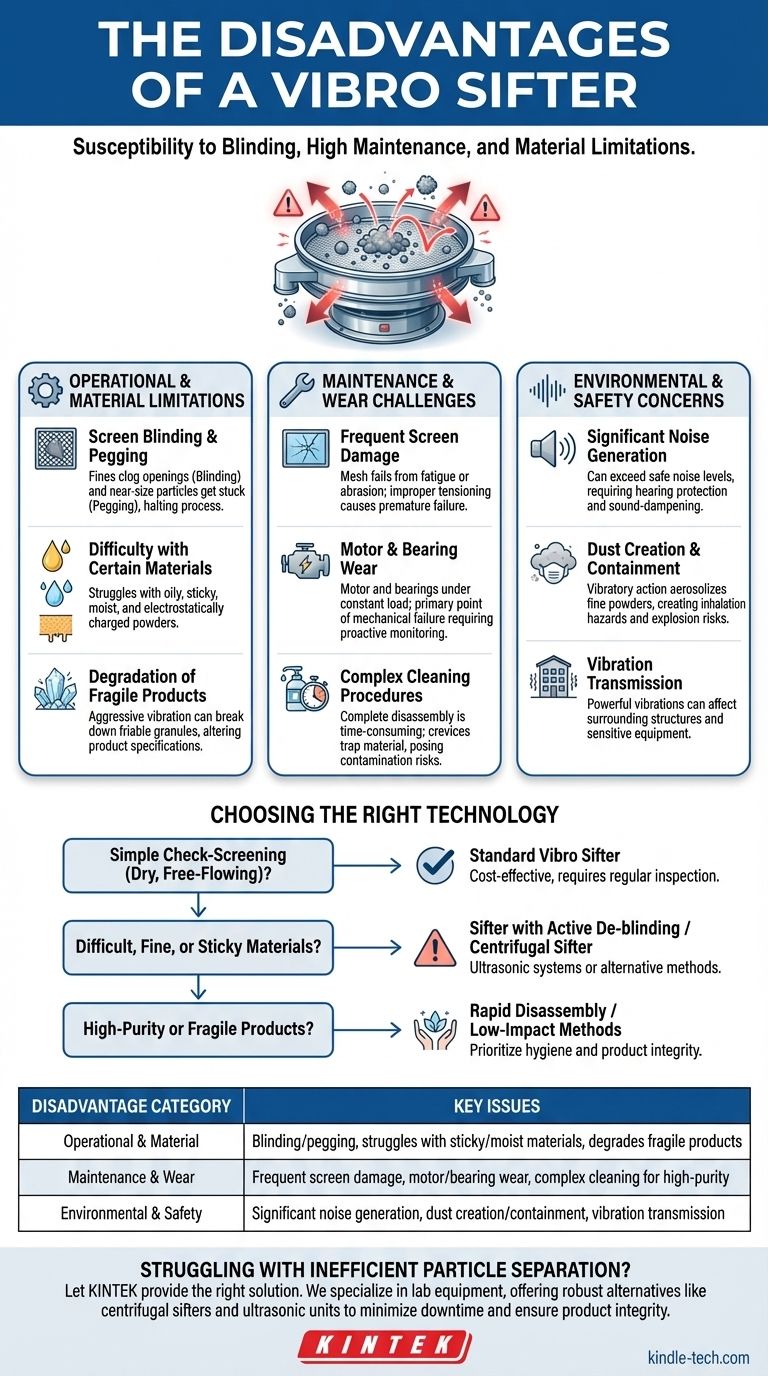

Operational and Material Limitations

The most frequent frustrations with vibro sifters arise during operation, often related to the nature of the material being processed.

Screen Blinding and Pegging

This is the single most common operational failure. Blinding occurs when fine particles clog the mesh openings, while pegging happens when near-size particles get stuck, effectively blocking the screen.

Both issues halt the separation process, drastically reduce throughput, and require production to be stopped for manual cleaning.

Difficulty with Certain Materials

Vibro sifters work best with dry, free-flowing powders. They struggle significantly with materials that are oily, sticky, or have high moisture content, as these tend to agglomerate and blind the screen almost immediately.

Similarly, very fine or electrostatically charged powders can be difficult to screen effectively as particles cling to each other and the screen mesh.

Degradation of Fragile Products

The high-frequency vibration necessary for separation can be too aggressive for delicate materials. It can easily break down friable granules, crystals, or agglomerated particles, altering the final product's specifications and creating unwanted fines.

Maintenance and Wear-Related Challenges

The mechanical nature of a vibro sifter means that key components are subjected to constant stress, leading to inevitable wear and the need for a rigorous maintenance schedule.

Frequent Screen Damage

The screen mesh is a consumable part. It can fail from fatigue cracking due to constant vibration, or from abrasion when processing hard materials. Improper screen tensioning is a leading cause of premature failure, leading to costly downtime and potential product contamination.

Motor and Bearing Wear

The motor with its eccentric weights is the heart of the machine. The bearings in this assembly are under constant load and are a primary point of mechanical failure. Proactive monitoring and replacement are essential to avoid catastrophic failure.

Complex Cleaning Procedures

For industries like food and pharmaceuticals requiring high levels of sanitation (GMP), a vibro sifter can be a liability. Complete disassembly for cleaning can be time-consuming, and the unit's many crevices and ledges can trap material, posing a cross-contamination risk.

Environmental and Safety Concerns

A vibro sifter's operation can have a direct impact on its immediate environment and the personnel working nearby.

Significant Noise Generation

Vibrating machinery is inherently noisy. A vibro sifter can easily exceed safe noise levels, often requiring operators to wear hearing protection and potentially necessitating sound-dampening enclosures.

Dust Creation and Containment

The vibratory action can aerosolize fine powders. If not properly contained with well-sealed lids and flexible connectors, this can lead to airborne dust, creating an inhalation hazard for operators and, in some cases, a combustible dust explosion risk.

Vibration Transmission

The machine's powerful vibrations can be transmitted through the floor to the surrounding building structure and other sensitive equipment. This requires proper installation on an isolated stand or with specialized mounting feet to mitigate the effect.

Is a Vibro Sifter Right for Your Application?

Choosing the right sifting technology depends entirely on your material, your process goals, and your operating environment.

- If your primary focus is simple check-screening of dry, free-flowing powders: A standard vibro sifter is often a cost-effective and reliable choice, provided you account for regular screen inspection.

- If you are processing difficult, fine, or sticky materials: You must invest in a sifter with an active de-blinding system (e.g., ultrasonic) or consider alternative technologies like a centrifugal sifter.

- If you operate in a high-purity environment or handle fragile products: Prioritize sifters designed for rapid, tool-free disassembly or explore lower-impact screening methods.

Understanding these potential disadvantages allows you to either engineer solutions for them or select a more suitable technology from the start.

Summary Table:

| Disadvantage Category | Key Issues |

|---|---|

| Operational & Material | Screen blinding/pegging, struggles with sticky/moist materials, degrades fragile products |

| Maintenance & Wear | Frequent screen damage, motor/bearing wear, complex cleaning for high-purity environments |

| Environmental & Safety | Significant noise generation, dust creation/containment issues, vibration transmission |

Struggling with inefficient or problematic particle separation? Let KINTCELT provide the right solution. We specialize in lab equipment and consumables, offering robust alternatives to vibro sifters, including centrifugal sifters and units with ultrasonic de-blinding systems. Our experts will help you select equipment that minimizes downtime, ensures product integrity, and meets your specific material and environmental needs. Contact our specialists today for a consultation and enhance your screening process!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is powder sieving? A Guide to Accurate Particle Size Separation

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab

- Why is sieve test important? Ensure Product Quality and Performance with Precise Particle Analysis

- What is the frequency of a sieve shaker? The Key to Accurate Particle Size Analysis

- What are the applications of sieving machine? From Mining to Pharmaceuticals