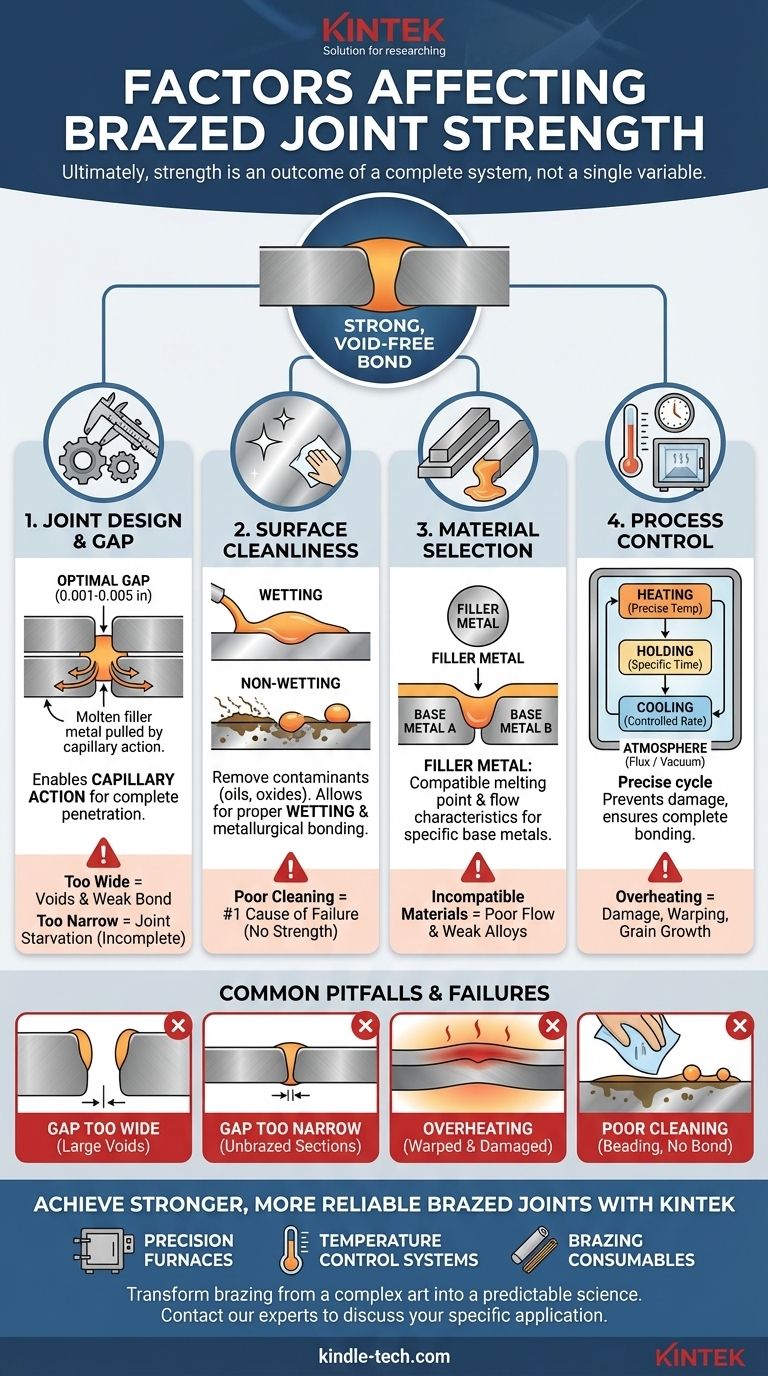

Ultimately, the strength of a brazed joint is determined by four primary factors: the design of the joint itself (especially the gap), the cleanliness of the surfaces, the selection of the correct filler metal, and the precise control of the heating and cooling process. When these elements are managed correctly, the resulting joint is not the weak point; it is stronger than the base metals being joined.

The core principle of brazing is that strength does not come from a single variable. It is an outcome of a complete system where joint design enables capillary action, clean surfaces allow for metallurgical bonding, and a controlled process executes the bond without damaging the components.

The Foundation: Joint Design and Preparation

A successful braze begins long before the parts are heated. The mechanical design and preparation of the joint are the most critical factors influencing the final strength.

The Critical Role of the Joint Gap

The space between the two surfaces being joined is known as the joint gap. This gap is not arbitrary; it is engineered to be extremely precise.

Its primary function is to allow capillary action to draw the molten filler metal completely into the joint.

An optimal gap, typically between 0.001 and 0.005 inches (0.025 to 0.127 mm), ensures the filler metal fills the entire interface, creating a strong, void-free bond.

Why Cleanliness is Non-Negotiable

The surfaces of the joint must be immaculately clean. Any contaminants, such as processing oils, grease, or even surface oxides, will prevent a successful braze.

These contaminants inhibit wetting, which is the ability of the molten filler metal to spread smoothly and evenly across the base metal surfaces.

Poor wetting results in a weak, incomplete bond or no bond at all. Proper cleaning often involves degreasing followed by a process to remove the specific oxide layer of the base metal.

Selecting the Right Materials

The materials chosen—both the base metals and the filler metal—must be compatible and selected for the specific application's demands.

Filler Metal Characteristics

The filler metal must have a melting temperature that is lower than that of the base metals being joined. This ensures the parts themselves do not melt during the process.

Crucially, the filler must be formulated to wet and flow on the specific base metals you are using. Different base metals (like steel, copper, or aluminum) require different filler metal alloys.

Base Metal Compatibility

The base metals themselves influence the process. For example, aluminum develops a tough, refractory oxide layer that must be removed or displaced by flux for the braze to succeed.

The strength and thermal properties of the base metals also dictate the maximum temperature and heating rates that can be used without causing damage or distortion.

Mastering the Brazing Process

The brazing process itself is a carefully controlled thermal cycle. Deviations in time, temperature, or atmosphere can compromise the joint.

Precise Temperature Control

The assembly must be heated uniformly to the correct brazing temperature, which is dictated by the filler metal.

If the temperature is too low, the filler metal will not melt and flow. If it is too high, it can damage the base metals or cause the filler metal to break down.

The Importance of Time and Cooling

The parts must be held at the brazing temperature for a specific holding time to allow the filler metal to flow throughout the joint and form a metallurgical bond.

The cooling rate is also critical. Cooling too quickly can introduce internal stresses and crack the joint, while cooling too slowly can lead to undesirable metallurgical changes.

The Role of Atmosphere (Flux or Vacuum)

During heating, metals react rapidly with oxygen to form oxides that prevent wetting. This must be prevented.

One method is using a flux, a chemical compound that shields the joint from air and dissolves oxides. The other is performing the braze in a vacuum furnace, which removes the oxygen from the environment entirely.

Understanding the Trade-offs and Failure Points

Achieving a perfect braze requires avoiding common pitfalls related to the core principles.

When the Joint Gap is Too Wide

If the gap is too large, capillary action will be weak or non-existent. The filler metal will fail to fill the joint completely, leading to large voids and a dramatically weaker bond that relies only on the low intrinsic strength of the filler alloy.

When the Joint Gap is Too Narrow

If the gap is too tight, the filler metal cannot flow into the joint at all. This "joint starvation" results in an incomplete, unreliable bond with large unbrazed sections.

The Danger of Overheating

Exceeding the recommended temperature can warp the parts, weaken the base metals through grain growth, or even melt them. This causes irreversible damage to the entire assembly, not just the joint.

The Consequence of Poor Cleaning

This is the most common cause of brazing failure. If the surface isn't clean, the filler metal will bead up like water on a waxed car instead of spreading. This creates a joint that may look complete but has almost no mechanical strength.

Making the Right Choice for Your Goal

To achieve a successful brazed joint, you must view the process holistically, where design, preparation, and process control are equally important.

- If your primary focus is process reliability and repeatability: Your priority must be stringent, documented cleaning protocols and precise control over the time-temperature cycle.

- If your primary focus is maximizing mechanical strength: Concentrate on engineering the correct joint design, particularly an optimal and consistent joint gap.

- If you are troubleshooting brazing failures: Always begin your investigation by examining the joint for evidence of poor cleaning (non-wetting) and measuring the joint gap of the failed components.

Mastering these interconnected factors is what transforms brazing from a complex art into a reliable and predictable engineering science.

Summary Table:

| Factor | Key Consideration | Impact on Strength |

|---|---|---|

| Joint Design & Gap | Optimal gap (0.001-0.005 in) for capillary action | Enables complete filler metal penetration and void-free bond |

| Surface Cleanliness | Removal of oils, grease, and oxides | Allows for proper wetting and metallurgical bonding |

| Filler Metal Selection | Compatibility with base metals and correct melting point | Ensures flow and formation of a strong metallurgical bond |

| Process Control | Precise temperature, time, and atmosphere (flux/vacuum) | Prevents base metal damage and ensures complete bonding |

Achieve stronger, more reliable brazed joints with KINTEK.

Whether you are developing new products or troubleshooting existing processes, the right equipment and consumables are critical for controlling the four key factors of brazing strength. KINTEK specializes in precision lab furnaces, temperature control systems, and brazing consumables that provide the repeatability and performance your laboratory needs.

Let us help you transform brazing from a complex art into a predictable science. Contact our experts today to discuss your specific application and how we can support your success.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- What is oxidation in brazing? How to prevent it for strong, durable joints

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques