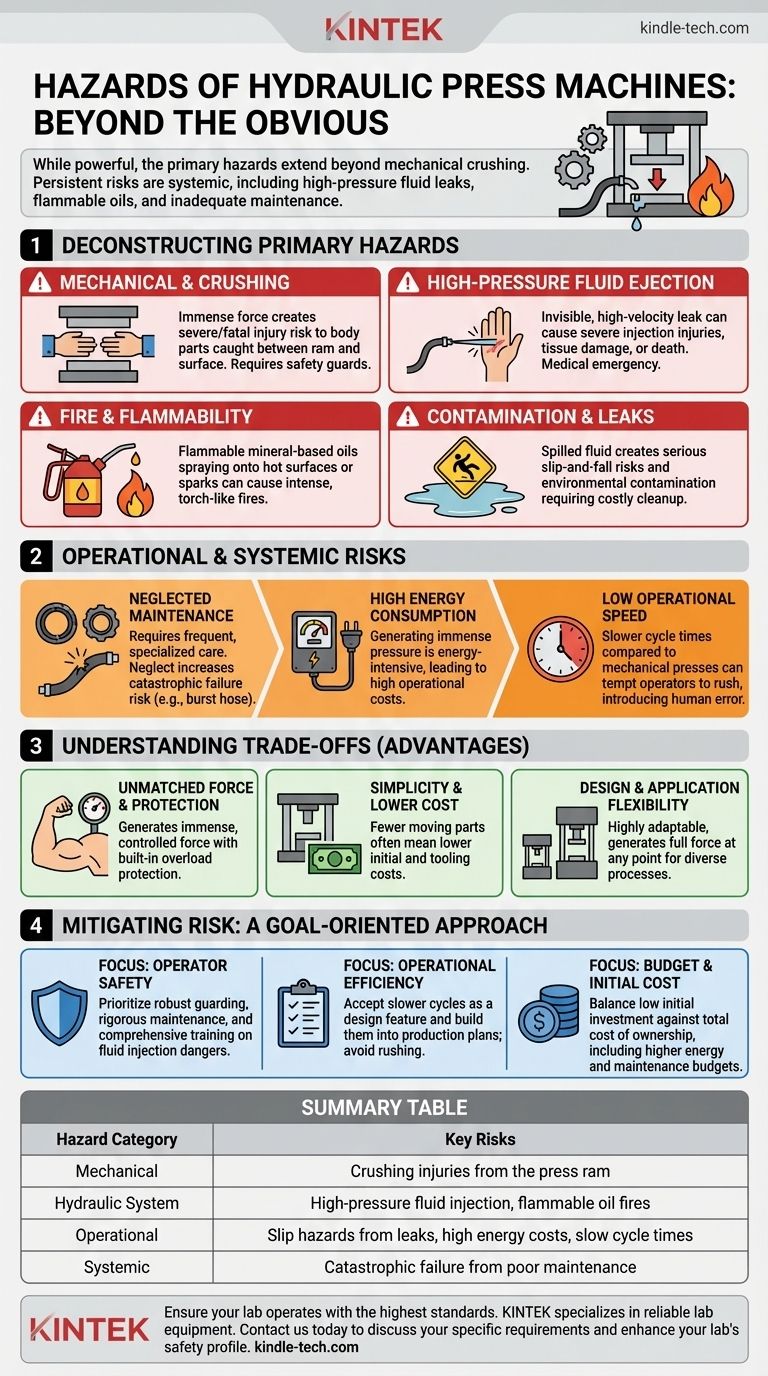

While powerful and versatile, the primary hazards of a hydraulic press machine extend far beyond the obvious mechanical crushing danger. The most persistent risks are often systemic, including the potential for high-pressure fluid leaks that can cause severe injection injuries, the use of flammable hydraulic oils creating a fire hazard, and the risk of catastrophic failure from inadequate maintenance.

The immense power of a hydraulic press often distracts from its most persistent hazards. While the risk of crushing is severe and must be guarded against, the true day-to-day operational risks stem from the hydraulic system itself: the high-pressure fluid, potential leaks, and the critical need for consistent maintenance.

Deconstructing the Primary Hazards

To operate a hydraulic press safely, you must understand each category of risk independently. The danger is not just from the moving parts but from the energy stored within the hydraulic system.

Mechanical and Crushing Hazards

The most apparent hazard is the immense force generated by the press. Any body part caught between the ram and the working surface will be subject to extreme tonnage, resulting in severe or fatal crushing injuries. This is the danger that most safety guards are designed to prevent.

High-Pressure Fluid Ejection

A leak in a high-pressure hydraulic line is not a simple drip. It can release a fine, near-invisible jet of fluid at a velocity high enough to penetrate skin and clothing. This type of high-pressure injection injury is a medical emergency that can lead to tissue damage, amputation, or death if not treated immediately.

Fire and Flammability

Many standard hydraulic systems use mineral-based oils that are flammable. A leak spraying this hot fluid onto an ignition source—such as a heater, electrical spark, or hot machinery—can result in a torch-like fire that is difficult to extinguish.

Contamination and Environmental Leaks

Even slow leaks pose a significant hazard. Spilled hydraulic fluid creates a serious slip-and-fall risk on the workshop floor. Furthermore, leaks represent an environmental contaminant that can lead to costly cleanup procedures and potential regulatory fines.

Operational and Systemic Risks

Beyond the immediate physical dangers, a hydraulic press carries operational risks that can impact safety, budget, and productivity.

The Cost of Neglected Maintenance

Hydraulic systems require more frequent and specialized maintenance than purely mechanical ones. Seals, hoses, and valves wear out over time. Neglecting this maintenance schedule doesn't just reduce efficiency; it dramatically increases the likelihood of a catastrophic failure, such as a burst hose or a failing cylinder.

High Energy Consumption

Generating immense hydraulic pressure is an energy-intensive process. These machines often have a high operational cost due to significant electricity consumption, which can become an economic liability if not factored into production costs.

Low Operational Speed

Compared to mechanical presses, hydraulic presses typically have slower cycle times. This limitation can sometimes tempt operators to bypass safety measures or rush procedures in an attempt to increase throughput, introducing human error as a major risk factor.

Understanding the Trade-offs

The hazards of a hydraulic press exist because of the engineering choices made to achieve its core benefits. Understanding these trade-offs is key to making an informed decision.

Advantage: Unmatched Force and Overload Protection

The primary reason for using a hydraulic press is its ability to generate immense, controlled force from a relatively simple design. Furthermore, these systems have built-in overload protection; the pressure relief valve prevents the machine from exceeding its maximum tonnage, protecting both the tool and the machine itself.

Advantage: Simplicity and Lower Cost

Hydraulic presses have a simpler design with fewer moving parts than complex mechanical presses. This often translates to a lower initial purchase cost and reduced mold or tooling expenses, making them highly accessible.

Advantage: Design and Application Flexibility

From small, portable laboratory units for sample preparation to massive industrial machines, hydraulic presses are highly adaptable. Their design allows them to generate full force at any point in the stroke, offering greater versatility for various manufacturing and testing processes.

Mitigating Risk: A Goal-Oriented Approach

Your strategy for managing hydraulic press hazards depends entirely on your operational priorities. A clear understanding of the risks allows for targeted mitigation.

- If your primary focus is operator safety: Your non-negotiable priorities must be robust physical guarding, a rigorous maintenance schedule for all hydraulic components, and comprehensive operator training that emphasizes the dangers of high-pressure fluid injection.

- If your primary focus is operational efficiency: You must accept the slower cycle times as a design characteristic and build them into your production plan, rather than creating an environment where operators feel pressured to rush.

- If your primary focus is budget and initial cost: Acknowledge that the low initial investment must be balanced against the total cost of ownership, which includes higher energy consumption and a dedicated budget for preventative maintenance.

By understanding the complete risk profile beyond the press ram, you can implement the right controls to operate a hydraulic press both safely and effectively.

Summary Table:

| Hazard Category | Key Risks |

|---|---|

| Mechanical | Crushing injuries from the press ram |

| Hydraulic System | High-pressure fluid injection, flammable oil fires |

| Operational | Slip hazards from leaks, high energy costs, slow cycle times |

| Systemic | Catastrophic failure from poor maintenance |

Ensure your lab operates with the highest standards of safety and efficiency. The hazards of hydraulic presses are manageable with the right equipment and knowledge. KINTEK specializes in providing reliable lab equipment and consumables, serving your laboratory's pressing needs. Let our experts help you select the right press and establish safe operating protocols. Contact us today to discuss your specific requirements and enhance your lab's safety profile.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What size sample for XRF? The Key to Accurate Elemental Analysis

- What affects the speed of a hydraulic motor? Master the balance of flow rate and displacement

- How do you use a KBr press? Master the Art of Creating Transparent Pellets for FTIR Analysis

- What will you do to reduce prevent excessive heating of oil in a hydraulic system? A Guide to Boosting Efficiency & Reliability

- What is the maximum operating temperature of a water based hydraulic fluid? Ensure Fire Safety and System Reliability

- How does a laboratory hydraulic press assist in XAS sample quality? Precision Pellets for Superior Spectral Clarity

- How do you prepare soil for XRF sample? A Step-by-Step Guide to Accurate Analysis

- How do you prepare samples for IR? A Guide to Solid, Liquid, and Gas Sample Prep