In short, plate and frame filter presses are industrial workhorses used for large-scale solid-liquid separation across an incredibly diverse set of industries. Their applications range from chemical manufacturing and mining to food and beverage processing, municipal wastewater treatment, and power generation. The core function in every case is to dewater a slurry, separating it into a solid cake and a clear liquid.

The versatility of the filter press comes from its simple, robust ability to solve a universal industrial problem: efficiently removing solids from a liquid stream. The specific goal may change—from waste reduction to product purification—but the fundamental principle of pressure filtration remains the same.

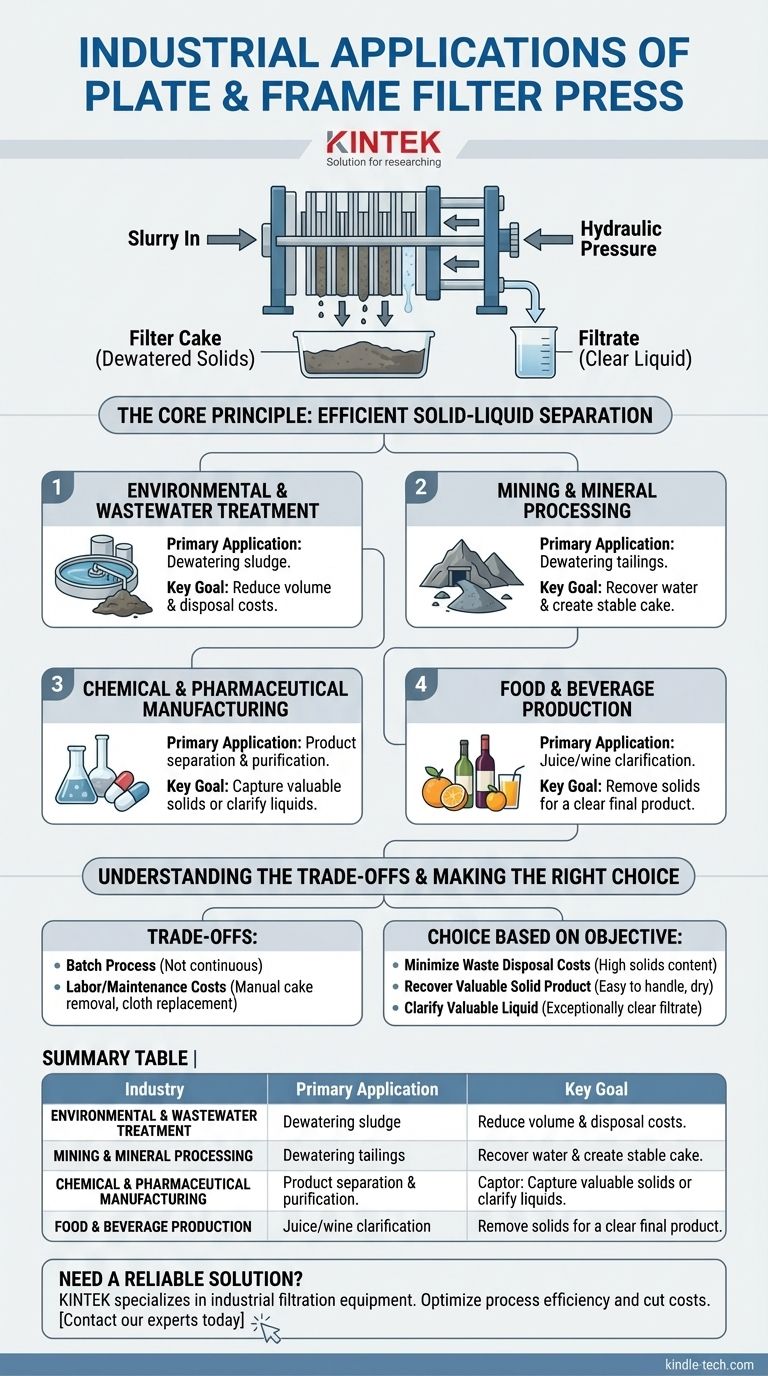

The Core Principle: Why Filter Presses Are So Widely Used

Before looking at specific industries, it's critical to understand why this technology is so adaptable. Its value lies in its straightforward and effective mechanical process.

How a Filter Press Works

A filter press operates by pumping a slurry (a mixture of solids and liquids) into a series of chambers. These chambers are formed by plates, covered in filter cloth, that are pressed together under immense hydraulic pressure. The liquid is forced through the cloth, leaving the solids behind.

The Two Key Outputs

Every filter press cycle produces two distinct outputs:

- Filter Cake: The dewatered, compressed solid material that accumulates between the plates.

- Filtrate: The clear liquid that has passed through the filter cloths.

The relative importance of the cake versus the filtrate depends entirely on the specific application.

The Goal: Maximizing Solid Capture or Liquid Clarity

An industry might use a filter press for one of two primary reasons. They may want to capture the solid "cake" as a valuable product, or they may want to clarify the liquid "filtrate" for discharge or further processing. Often, the goal is simply to reduce the volume of waste sludge to minimize disposal costs.

Key Industrial Applications in Practice

The simple principle of separating a slurry into a cake and a filtrate is applied to solve different problems in different sectors.

Environmental and Wastewater Treatment

This is one of the most common applications. Municipal plants, power generation facilities, steel mills, and asphalt production sites all generate wastewater with suspended solids. A filter press is used to dewater the resulting sludge, drastically reducing its volume and weight, which significantly cuts down on transportation and disposal costs.

Mining and Mineral Processing

In the mining and aggregates industries, filter presses dewater mineral tailings. This process serves two purposes: recovering process water so it can be reused in the plant and producing a dry, stackable tailings cake that is safer and more economical to manage than a wet tailings pond.

Chemical and Pharmaceutical Manufacturing

Chemical plants use filter presses to separate a valuable solid product from a liquid reaction mixture. It's also used to remove impurities from a liquid stream or to dewater sludge from the plant's on-site wastewater treatment process.

Food and Beverage Production

The food industry uses this technology for clarification. For example, filter presses are used to remove pulp from fruit juices or yeast from beer and wine to create a clear, polished final product. They are also used to process waste streams from production.

Understanding the Trade-offs

While highly effective, the plate and frame filter press is not the right solution for every situation. Its primary limitations stem from its operational design.

Batch vs. Continuous Operation

A filter press is a batch process. It fills, presses, empties, and repeats. This cycle means the process flow is not continuous, which can be a drawback compared to technologies like centrifuges or belt presses that operate continuously.

Labor and Maintenance Costs

Clearing the solid filter cake from the press often requires manual intervention, though automated systems exist. The filter cloths are also consumable components that wear out and require periodic replacement, adding to operational costs and downtime.

Making the Right Choice for Your Goal

To determine if a filter press is the right technology, consider your primary objective.

- If your primary focus is minimizing waste disposal costs: The filter press is a leading technology for dewatering sludge to achieve a high solids content, dramatically reducing hauling expenses.

- If your primary focus is recovering a valuable solid product: A filter press is excellent for capturing and dewatering solids in a form that is easy to handle, dry, and process further.

- If your primary focus is clarifying a valuable liquid: The technology is highly effective at producing an exceptionally clear filtrate, making it ideal for processes like juice or wine production.

Ultimately, the filter press remains a cornerstone of industrial processing because it provides a reliable and powerful solution to the fundamental challenge of separating solids from liquids.

Summary Table:

| Industry | Primary Application | Key Goal |

|---|---|---|

| Wastewater Treatment | Dewatering sludge | Reduce volume & disposal costs |

| Mining & Minerals | Dewatering tailings | Recover water & create stable cake |

| Chemical & Pharma | Product separation & purification | Capture valuable solids or clarify liquids |

| Food & Beverage | Juice/wine clarification | Remove solids for a clear final product |

Need a reliable solution for your solid-liquid separation challenges? KINTEK specializes in industrial filtration equipment, including robust plate and frame filter presses. Whether your goal is waste reduction, product recovery, or liquid clarification, our expertise can help you optimize your process efficiency and cut costs. Contact our experts today to discuss your specific application and find the perfect fit for your laboratory or industrial needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy