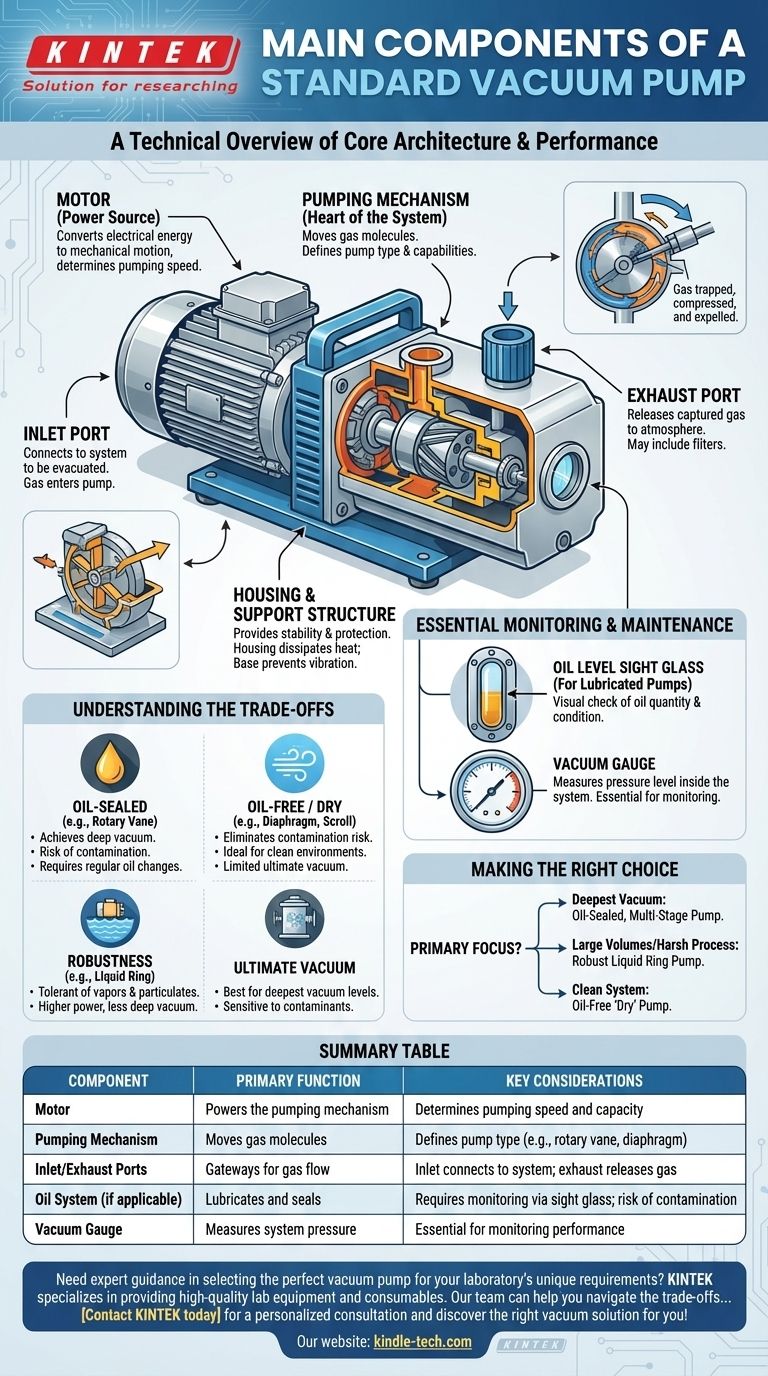

At its core, a standard vacuum pump is a system designed to remove gas molecules from a sealed space. Its primary components consist of an electric motor that powers a pumping mechanism (or compressor), an inlet port to connect to the system being evacuated, and an exhaust port to release the captured gas into the atmosphere. These are supported by a housing, a base for stability, and often a handle for portability.

While specific designs vary, every vacuum pump operates on the same principle: a powered mechanism that captures gas at a low-pressure inlet and expels it at a higher-pressure outlet. Understanding the function of each core component is the key to operating the pump effectively and selecting the right tool for the job.

The Core Architecture of a Vacuum Pump

Every vacuum pump, regardless of its specific technology, is built around a few fundamental components that work in concert to create a pressure differential.

The Motor: The Power Source

The motor is the engine of the pump. It converts electrical energy into the mechanical motion required to drive the pumping mechanism. The size and power of the motor are directly related to the pump's capacity, or its pumping speed.

The Pumping Mechanism: The Heart of the System

This is the component that does the actual work of moving gas molecules. It's often housed within a "pump head" or compressor unit. The design of this mechanism defines the type of pump and its capabilities.

In many standard pumps, like a rotary vane pump, this involves an offset rotor with sliding vanes inside a chamber. As the rotor turns, it creates expanding pockets of space at the inlet to trap gas, then compresses and pushes that gas out the exhaust. The rotor is often the only major moving part.

Inlet and Exhaust Ports: The Gateways for Gas

The inlet port is the connection point for the system you need to evacuate. It's where gas from your chamber or vessel enters the pump.

The exhaust port is where the captured and compressed gas is released, typically to the ambient atmosphere. This port may also include filters to capture oil mist on lubricated pumps.

The Housing and Support Structure

These components provide physical stability and protection. A support base prevents the pump from vibrating or moving during operation, while a rigid housing protects the internal components and helps dissipate heat.

Essential Monitoring and Maintenance Components

Beyond the core architecture, several other parts are critical for proper operation and longevity, especially in common oil-sealed pumps.

The Oil System (for Lubricated Pumps)

Many high-vacuum pumps use a special oil to create seals, lubricate moving parts, and help capture gas molecules. An oil level sight glass is a transparent window that allows you to visually check the quantity and condition of the oil, which is crucial for pump health.

The Vacuum Gauge: Measuring Performance

While sometimes an external accessory, a vacuum gauge is an indispensable part of any vacuum process. It measures the pressure level inside the system, allowing you to know when your target vacuum has been achieved. Without it, you are operating blind.

Understanding the Trade-offs

The specific components and design of a pump represent a series of engineering trade-offs. The "best" pump is always relative to the application's demands.

Oil-Sealed vs. Oil-Free ("Dry") Pumps

Oil-sealed pumps (like rotary vane pumps) can achieve very deep vacuum levels because the oil creates an excellent seal. However, they carry a risk of oil vapor back-streaming and contaminating the vacuum system, and they require regular oil changes.

Oil-free or "dry" pumps (like diaphragm or scroll pumps) eliminate this contamination risk, making them ideal for clean environments. The trade-off is that they often cannot achieve the same deep vacuum levels as their oil-sealed counterparts.

Robustness vs. Ultimate Vacuum

Some pumps are designed for harsh industrial environments. A liquid ring vacuum pump, for instance, uses a ring of centrifuged liquid (often water) as its sealant.

This design makes it highly tolerant of vapors, small particles, and liquids that would destroy a more sensitive oil-sealed pump. The trade-off is a higher power consumption and a less deep ultimate vacuum, limited by the vapor pressure of the sealing liquid.

Making the Right Choice for Your Goal

Selecting a pump means matching its components and design principles to your primary objective.

- If your primary focus is achieving the deepest possible vacuum: An oil-sealed, multi-stage rotary vane pump is the standard choice for this goal.

- If your primary focus is moving large volumes of gas in a harsh industrial process: A liquid ring pump offers unmatched robustness, especially when dealing with vapors or particulates.

- If your primary focus is maintaining a perfectly clean, contaminant-free system: An oil-free "dry" pump, such as a diaphragm or scroll pump, is the only suitable option.

By understanding how each component contributes to the pump's overall performance, you can confidently select and operate the correct equipment for your specific application.

Summary Table:

| Component | Primary Function | Key Considerations |

|---|---|---|

| Motor | Powers the pumping mechanism | Determines pumping speed and capacity |

| Pumping Mechanism | Moves gas molecules | Defines pump type (e.g., rotary vane, diaphragm) |

| Inlet/Exhaust Ports | Gateways for gas flow | Inlet connects to system; exhaust releases gas |

| Oil System (if applicable) | Lubricates and seals | Requires monitoring via sight glass; risk of contamination |

| Vacuum Gauge | Measures system pressure | Essential for monitoring performance |

Need expert guidance in selecting the perfect vacuum pump for your laboratory's unique requirements?

KINTEK specializes in providing high-quality lab equipment and consumables. Our team can help you navigate the trade-offs between oil-sealed, oil-free, and robust liquid ring pumps to ensure you get the performance, cleanliness, and durability your applications demand.

Contact KINTALK today for a personalized consultation and discover the right vacuum solution for you!

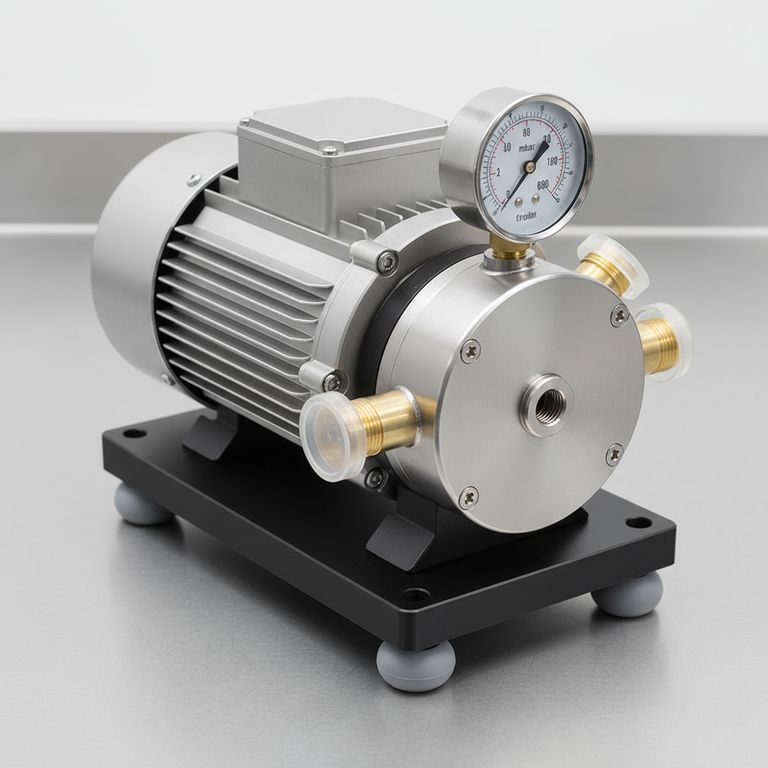

Visual Guide

Related Products

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

People Also Ask

- Why refractory materials are used in furnaces? Ensure Safety, Efficiency, and Process Purity

- What grinding consumables are recommended for transition metal borides? Achieve High-Purity Micron Powders

- What function do magnetic stirrers perform in SLM silver separation? Optimize Mass Transfer for Silver Recovery

- What is the primary purpose of using graphite foil to wrap Tantalum Carbide samples? Ensure Pure & Precise Sintering

- What are the advantages and disadvantages of refractory materials? Balancing Heat Resistance with Cost & Durability

- Why are agate grinding jars preferred over metal jars for LLZO powders? Ensure Ultra-High Purity in Milling

- Why does the pressure switch keep tripping on my furnace? Diagnose the Root Cause and Restore Heat

- What is metallographic sandpaper and how should it be used? A Guide to Flawless Sample Preparation