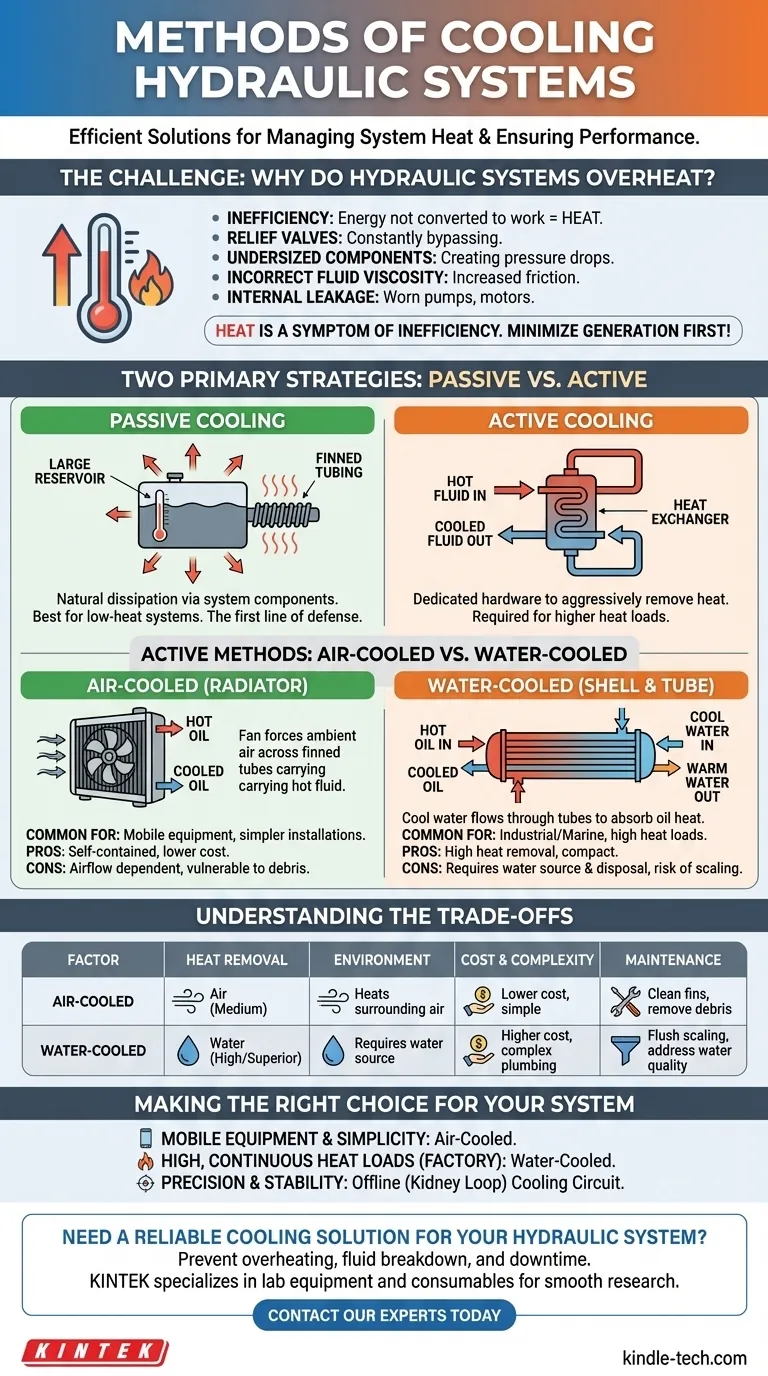

The primary methods for cooling a hydraulic system fall into two categories: passive and active. Passive cooling relies on natural heat dissipation through components like a large reservoir tank and finned tubing. Active cooling uses dedicated heat exchangers, which are most commonly either air-cooled (like a car's radiator) or water-cooled (using a shell-and-tube design) to aggressively remove heat from the hydraulic fluid.

The central challenge in hydraulic cooling is not just removing heat, but understanding that heat is a direct symptom of system inefficiency. The most robust solution always starts with minimizing heat generation before selecting an appropriate cooling method to manage the unavoidable remainder.

Why Do Hydraulic Systems Overheat?

Before choosing a cooling method, it is critical to understand the source of the heat. In any hydraulic system, heat is simply a waste product—energy that is not converted into useful work.

Inefficiency is the Source of Heat

Every time hydraulic fluid flows through a component, it experiences a pressure drop.

If that pressure drop does not perform work (like moving a cylinder or turning a motor), the energy is converted directly into heat. This is a fundamental principle of thermodynamics.

Common Causes of Unnecessary Heat

Excess heat is often a sign of a design flaw or a maintenance issue. Common culprits include:

- Relief Valves: A constantly bypassing relief valve is a major heat source.

- Undersized Components: Small lines, valves, or filters force the pump to work harder, creating pressure drops and heat.

- Incorrect Fluid Viscosity: Fluid that is too thick or too thin increases friction and inefficiency.

- Internal Leakage: Worn pumps, motors, or cylinders allow high-pressure fluid to leak internally, generating significant heat.

Passive vs. Active Cooling Strategies

The approach to managing this waste heat can be broken down into two distinct strategies.

Passive Cooling: The First Line of Defense

Passive cooling leverages the system's own components to radiate heat into the surrounding environment without dedicated cooling hardware.

The most significant component is the hydraulic reservoir. A large reservoir provides a greater surface area for heat to dissipate and allows the fluid more time to cool naturally. Using steel tubing instead of hoses where possible can also help radiate heat.

Active Cooling: When Passive Isn't Enough

When passive methods are insufficient for the system's heat load, an active cooling circuit is required.

This involves adding a heat exchanger—a device specifically designed to transfer thermal energy from the hydraulic oil to another medium, like air or water.

A Closer Look at Active Cooling Methods

Active coolers are integrated into the hydraulic circuit to directly target and remove heat from the fluid.

Air-Cooled Heat Exchangers

An air-cooled heat exchanger, often called a radiator, works by passing hot hydraulic fluid through a series of tubes.

These tubes are covered in thin fins to maximize the surface area exposed to the air. A fan (either electric or engine-driven) forces ambient air across these fins, carrying the heat away. This is the most common method used in mobile hydraulic applications.

Water-Cooled Heat Exchangers

A water-cooled heat exchanger is typically a shell-and-tube design. In this configuration, the hot hydraulic oil flows through the "shell" while cool water flows through a bundle of tubes inside it.

The heat transfers from the oil to the water, which is then discharged. This method is extremely efficient and is common in industrial or marine settings where a steady supply of cool water is available.

Offline vs. In-line Cooling

A cooler can be placed in-line, typically on the main return line before the fluid enters the reservoir. This is a simple and common installation.

Alternatively, an offline cooling loop (or "kidney loop") uses a separate, small pump to constantly circulate fluid from the reservoir, through the heat exchanger, and back to the tank. This provides more consistent cooling that is independent of the main system's operation.

Understanding the Trade-offs: Air vs. Water

Choosing between air and water cooling involves balancing performance, cost, and environmental factors.

Heat Removal Capacity

Water is vastly more effective at absorbing and carrying away heat than air. For systems with very high and continuous heat loads, a water-cooled exchanger is the most powerful solution.

Environmental Considerations

Air coolers transfer heat directly to the surrounding air, which can be an issue in enclosed or already hot environments.

Water coolers require a consistent source of water (from a tower, chiller, or municipal supply) and a plan for its disposal. Water quality is also a concern, as hard water can cause scaling and reduce efficiency.

Cost and Complexity

Air coolers are often self-contained units that are simpler and less expensive to install.

Water coolers require additional plumbing for the water supply and return, increasing installation complexity and introducing more potential points of failure (leaks, corrosion).

Maintenance Requirements

Air coolers are vulnerable to clogging from airborne debris like dust, dirt, and oil mist, which can insulate the fins and drastically reduce performance. They require regular cleaning.

Water coolers can suffer from internal blockages due to mineral deposits (scaling), sediment, or biological growth, which may require chemical flushing.

Making the Right Choice for Your System

Your selection should be based on a clear understanding of your application's demands and operating environment. First, focus on designing an efficient system that generates minimal waste heat, then select a cooler to handle the remaining thermal load.

- If your primary focus is mobile equipment or installation simplicity: An air-cooled heat exchanger is almost always the correct choice.

- If your primary focus is managing high, continuous heat loads in a factory: A water-cooled system offers superior and more compact thermal performance.

- If your primary focus is precision and stability: An offline (kidney loop) cooling circuit provides consistent temperature control independent of machine duty cycles.

Proactive thermal management is the foundation of a reliable and long-lasting hydraulic system.

Summary Table:

| Method | How It Works | Best For |

|---|---|---|

| Passive Cooling | Natural heat dissipation via reservoir/tubing | Low-heat systems, first-line defense |

| Air-Cooled (Radiator) | Fan forces air over finned tubes containing hot oil | Mobile equipment, simpler installations |

| Water-Cooled (Shell & Tube) | Cool water flows through tubes to absorb oil heat | High-heat industrial settings, maximum efficiency |

Need a reliable cooling solution for your hydraulic system?

Overheating leads to fluid breakdown, component wear, and costly downtime. KINTEK specializes in the lab equipment and consumables that keep your systems—and your research—running smoothly and efficiently.

Contact our experts today to discuss your specific thermal management challenges and discover the right solution for your laboratory's needs.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Platinum Auxiliary Electrode for Laboratory Use

- Silicon Carbide (SIC) Ceramic Sheet Flat Corrugated Heat Sink for Engineering Advanced Fine Ceramics

People Also Ask

- How should an oil-free diaphragm vacuum pump be maintained? A Proactive Guide to Maximize Pump Lifespan

- What types of gases can a water circulating vacuum pump handle? Safely Manage Flammable, Condensable & Dirty Gases

- What are the advantages of using oil-free diaphragm vacuum pumps? Achieve Clean, Low-Maintenance Vacuum

- How does an oil-free diaphragm vacuum pump work? A Guide to Clean, Contamination-Free Vacuum

- What factors should be considered when selecting an oil-free diaphragm vacuum pump? A Guide to Optimal Performance & Longevity