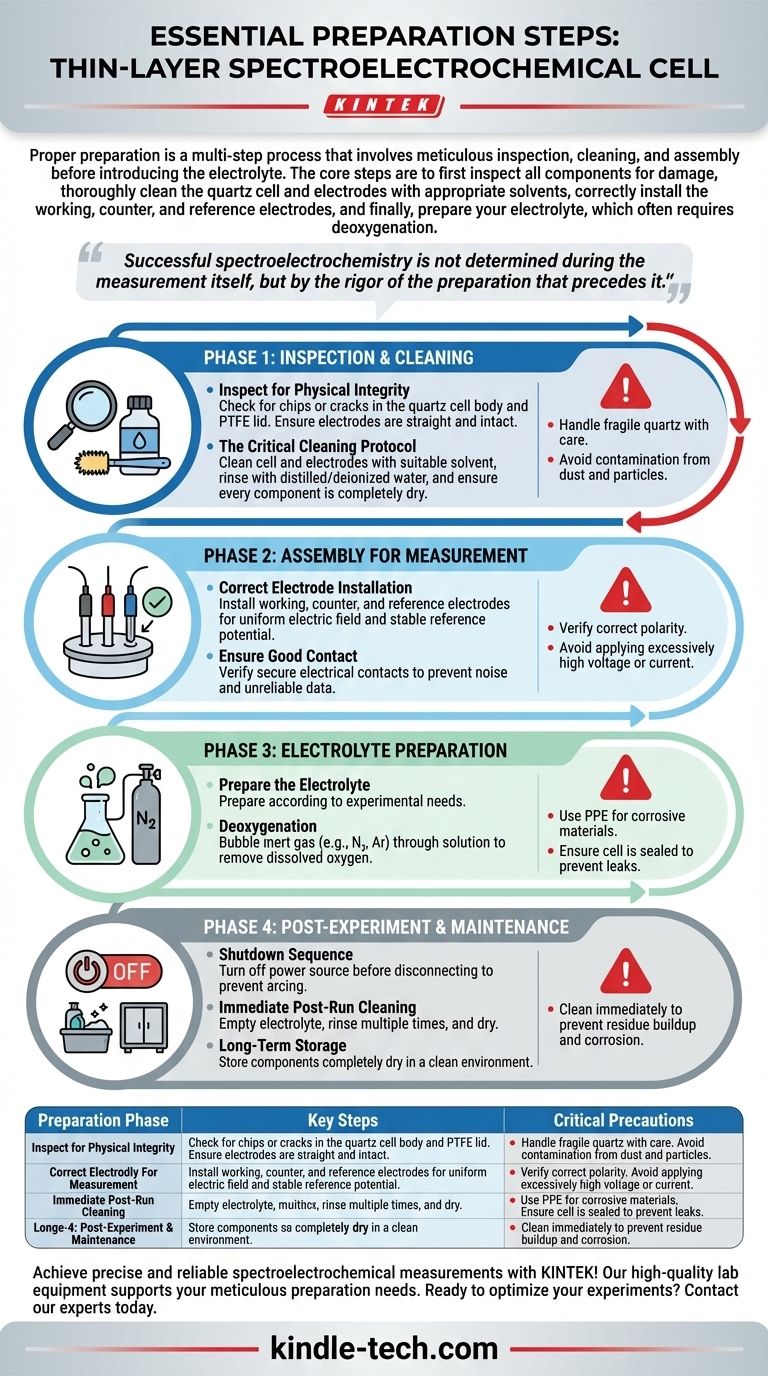

Proper preparation is a multi-step process that involves meticulous inspection, cleaning, and assembly before introducing the electrolyte. The core steps are to first inspect all components for damage, thoroughly clean the quartz cell and electrodes with appropriate solvents, correctly install the working, counter, and reference electrodes, and finally, prepare your electrolyte, which often requires deoxygenation.

Successful spectroelectrochemistry is not determined during the measurement itself, but by the rigor of the preparation that precedes it. The goal is to create a pristine and controlled environment, as any oversight in cleaning, assembly, or handling will directly compromise the integrity of your results.

Foundational Steps: Inspection and Cleaning

The first phase of preparation is entirely focused on ensuring the cell is physically sound and chemically inert, preventing leaks, and removing any contaminants that could interfere with your measurement.

Inspecting for Physical Integrity

Before you begin, perform a visual inspection of all components. Look for chips or cracks in the quartz cell body, as its integrity is crucial for containing the sample and providing a clear optical path.

The cell body is typically made from integrally polished quartz, which is fragile. Also, check the PTFE lid and ensure all electrodes are straight and their contact points are intact.

The Critical Cleaning Protocol

Contaminants from previous experiments or storage can introduce unwanted electrochemical or spectroscopic signals. A thorough cleaning is non-negotiable.

Begin by cleaning the cell and electrodes with a suitable solvent to remove organic or inorganic residues. Follow this with a comprehensive rinse using distilled or deionized water.

Finally, ensure every component is completely dry before assembly. Any residual moisture can dilute your electrolyte and alter the reaction environment.

Assembling the Cell for Measurement

With a clean and dry cell, the next stage is to correctly assemble the electrochemical components. The precision of this assembly directly impacts the quality of your electrical connections and the stability of the experiment.

Correct Electrode Installation

Install the working, counter, and reference electrodes into the cell lid. The positioning is critical to ensure a uniform electric field and stable reference potential.

Ensure each electrode has a good electrical contact with its connector. A loose connection is a common source of noise and unreliable data.

Preparing the Electrolyte

Your electrolyte solution must be prepared according to your experimental needs. For many systems, removing dissolved oxygen is a critical step.

Deoxygenation, typically achieved by bubbling an inert gas like nitrogen or argon through the solution, prevents oxygen from acting as an unwanted electrochemical reactant.

Understanding Critical Precautions

Mistakes during setup can lead to poor data, equipment damage, or safety hazards. Understanding these risks is as important as knowing the procedure itself.

Preventing Contamination

The experiment is highly sensitive to impurities. Keep the cell covered whenever possible to prevent dust or other airborne particles from entering the electrolyte.

Electrical Safety and Equipment Protection

Always verify the correct polarity for the anode and cathode connections to your potentiostat. Reversing the polarity can cause irreversible damage to your sample or electrodes.

Avoid applying an excessively high voltage or current, which can lead to electrolyte decomposition, electrode damage, and erroneous results.

Handling Corrosive Materials

If using corrosive electrolytes, always wear appropriate personal protective equipment (PPE), including gloves and safety glasses. Ensure the cell is sealed properly to prevent leaks.

Protecting the Quartz Cell Body

The quartz body is extremely fragile. Handle it with care at all times, avoiding physical shock or rapid temperature changes that could cause it to crack.

Post-Experiment: Proper Shutdown and Maintenance

Proper care after an experiment ensures the longevity of the cell and makes preparation for the next run more efficient.

The Shutdown Sequence

Before disconnecting any wires, always turn off the power source at the electrochemical workstation. This prevents electrical arcing that could damage the instrument or the cell's electrodes.

Immediate Post-Run Cleaning

Promptly empty the electrolyte from the cell. Rinse the cell and electrodes multiple times with distilled water or an appropriate solvent to remove all residual reactants and products.

Long-Term Storage Best Practices

After cleaning, ensure the cell, electrodes, and all other parts are completely dry. Store them in a clean, dry environment, protected from dust and moisture to prevent corrosion or contamination.

Making the Right Choice for Your Goal

Your specific priorities will determine which preparation steps demand the most attention.

- If your primary focus is data accuracy: Pay extreme attention to the cleaning protocol and electrolyte deoxygenation to eliminate interfering signals.

- If your primary focus is equipment longevity: Emphasize careful handling of the fragile quartz cell and immediate, thorough cleaning after each use.

- If your primary focus is safety: Double-check all electrical connections for correct polarity and always use appropriate PPE when handling hazardous electrolytes.

Ultimately, meticulous and consistent preparation is the foundation upon which reliable spectroelectrochemical data is built.

Summary Table:

| Preparation Phase | Key Steps | Critical Precautions |

|---|---|---|

| Inspection & Cleaning | Inspect quartz cell for damage; clean with solvents and water; ensure components are dry. | Handle fragile quartz with care; avoid contamination. |

| Assembly | Correctly install working, counter, and reference electrodes; ensure good electrical contact. | Verify correct polarity; avoid high voltage/current. |

| Electrolyte Prep | Prepare electrolyte; deoxygenate with inert gas (e.g., N₂). | Use PPE for corrosive materials; prevent leaks. |

| Post-Experiment | Turn off power; rinse cell and electrodes; dry and store properly. | Clean immediately to prevent residue buildup. |

Achieve precise and reliable spectroelectrochemical measurements with KINTEK!

Our high-quality lab equipment, including durable spectroelectrochemical cells and reliable electrodes, is designed to support your meticulous preparation needs. Whether you prioritize data accuracy, equipment longevity, or safety, KINTEK provides the tools to enhance your lab's efficiency and results.

Ready to optimize your experiments? Contact our experts today to find the perfect solution for your laboratory requirements.

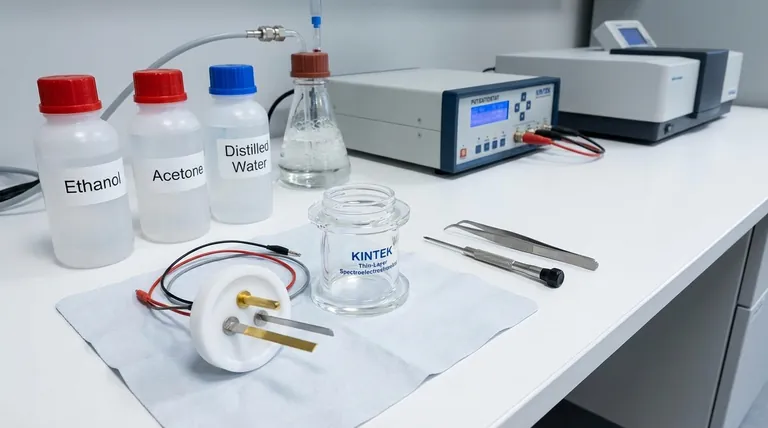

Visual Guide

Related Products

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What are the dimensions for thin-layer spectroelectrochemical cells? Optimize Your Lab's Optical Path Length

- What are the key maintenance and handling procedures for a thin-layer spectroelectrochemical cell? Protect Your Sensitive Lab Equipment

- What preparation steps are required before initiating an experiment with the thin-layer spectroelectrochemical cell?

- What types and sizes of electrodes are typically configured with a thin-layer spectroelectrochemical cell? Standard Setup for Accurate Analysis

- Which electrode types are compatible with thin-layer spectroelectrochemical cells? Optimize Your Hardware Fit