The correct post-experiment procedure for a thin-layer spectroelectrochemical cell is a systematic process designed to ensure safety, preserve the integrity of the equipment, and guarantee the quality of future results. The protocol begins with safely powering down the equipment, followed by meticulously emptying, rinsing, and disassembling the cell. Each component, especially the electrodes, must then be thoroughly cleaned, completely dried, and stored in a protected environment.

The primary goal of the post-experiment procedure extends beyond simple cleanup. It is a critical step in maintaining the cell's delicate components and preventing cross-contamination, thereby safeguarding the accuracy and reproducibility of your subsequent experiments.

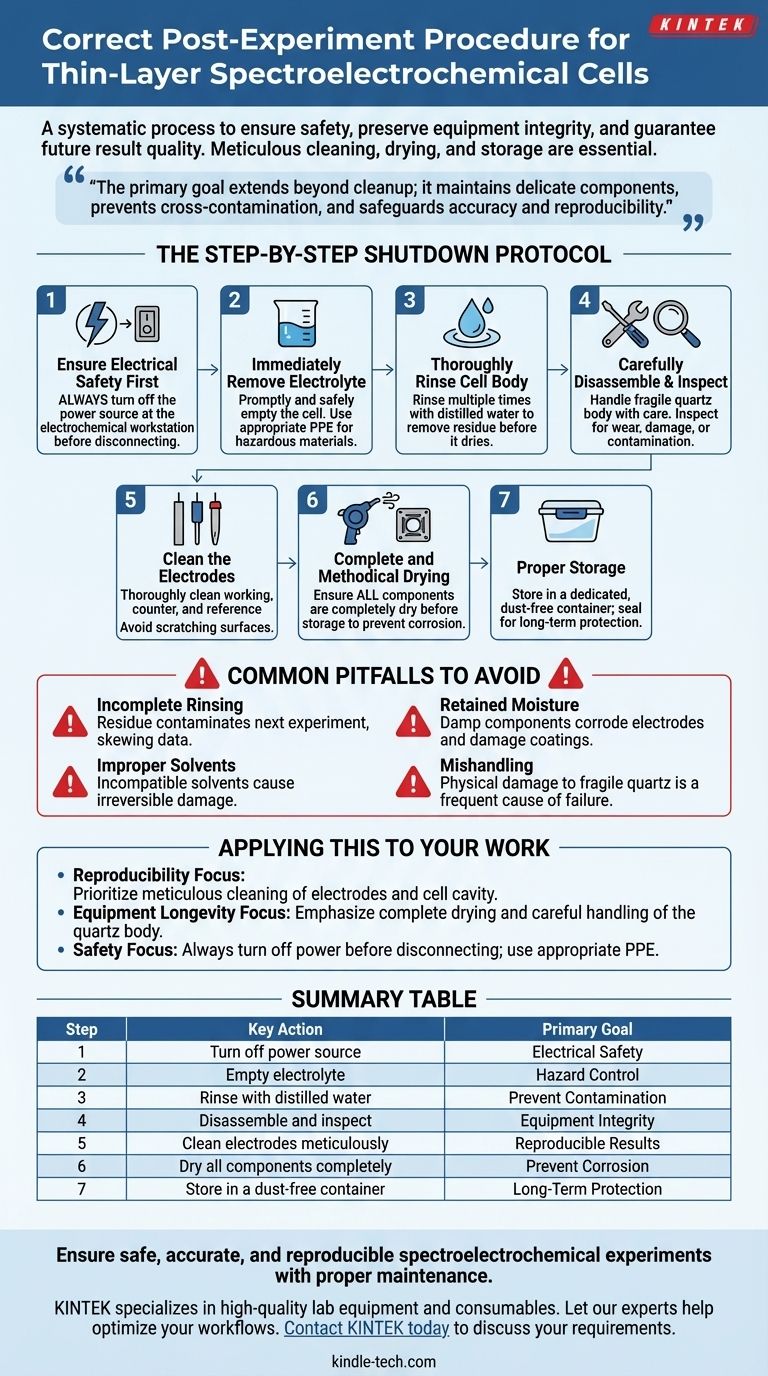

The Step-by-Step Shutdown Protocol

Following a strict, sequential process is essential for protecting both the user and the sensitive instrumentation. Each step has a specific purpose related to safety, equipment longevity, or data integrity.

Step 1: Ensure Electrical Safety First

Before touching any connections, always turn off the power source at the electrochemical workstation. Disconnecting the cell while it is still energized can cause electrical arcing, which poses a safety hazard and can damage the equipment's electronic components.

Step 2: Immediately Remove the Electrolyte

Once the power is off, promptly and safely empty the electrolyte from the cell. If working with corrosive or hazardous materials, use appropriate personal protective equipment (PPE) and follow laboratory safety guidelines for disposal.

Step 3: Thoroughly Rinse the Cell Body

Immediately rinse the cell multiple times with distilled water or another appropriate solvent. This step is critical for removing any residual electrolyte and reaction byproducts before they have a chance to dry, crystallize, or adsorb onto the cell surfaces.

Step 4: Carefully Disassemble and Inspect

Carefully disassemble the cell, paying close attention to the electrodes and the cell body. The quartz body is particularly fragile and must be handled with care to prevent chipping or breakage. Use this opportunity to inspect each component for signs of wear, damage, or contamination.

Step 5: Clean the Electrodes

Thoroughly clean the working, counter, and reference electrodes according to their specific material requirements. This may involve using specific solvents or gentle polishing, but avoid any method that could scratch or damage the electrode surfaces. This is non-negotiable for reproducible results.

Step 6: Complete and Methodical Drying

Ensure every component—the cell body, electrodes, and any seals or fittings—is completely dry before storage. Any retained moisture can lead to corrosion of metallic parts or promote the growth of contaminants over time.

Step 7: Proper Storage for Future Use

Store the clean, dry components in a dedicated, dust-free container. For long-term storage, it is best practice to keep the cell sealed to protect it from atmospheric moisture and contaminants.

Common Pitfalls to Avoid

Mistakes in the shutdown procedure are a primary source of experimental error and equipment failure. Understanding these common pitfalls is key to maintaining a reliable experimental setup.

The Risk of Incomplete Rinsing

Failing to rinse the cell thoroughly can leave behind a microscopic film of reactants or products. This residue can contaminate your next experiment, leading to skewed data, unexpected side reactions, or "ghost peaks" in your analysis.

The Danger of Improper Solvents

Using a solvent that is incompatible with the cell's materials can cause irreversible damage. Aggressive solvents may corrode metal components, degrade seals, or etch the surface of the quartz window, compromising its optical clarity.

The Consequence of Retained Moisture

Storing components while they are still even slightly damp is a common mistake. Moisture accelerates the corrosion of electrodes and can damage sensitive coatings, fundamentally altering their electrochemical behavior and shortening their lifespan.

The Hazard of Mishandling

The most frequent cause of catastrophic cell failure is physical damage. The delicate nature of the quartz body means that even a small impact can cause a fracture, rendering the entire cell unusable. Always handle it with deliberate care.

Applying This to Your Work

Your specific focus will determine which parts of this protocol require the most attention.

- If your primary focus is reproducibility: Prioritize the meticulous cleaning of the electrodes and the cell cavity to eliminate any trace of chemical residue.

- If your primary focus is equipment longevity: Emphasize complete drying of all components before storage and extremely careful handling of the fragile quartz cell body.

- If your primary focus is safety: Make it an unbreakable rule to always turn off the power source before disconnecting the cell and to use appropriate PPE when handling electrolytes.

Adhering to this disciplined procedure transforms it from a routine chore into a fundamental part of reliable and successful science.

Summary Table:

| Step | Key Action | Primary Goal |

|---|---|---|

| 1 | Turn off power source | Electrical Safety |

| 2 | Empty electrolyte | Hazard Control |

| 3 | Rinse with distilled water | Prevent Contamination |

| 4 | Disassemble and inspect | Equipment Integrity |

| 5 | Clean electrodes meticulously | Reproducible Results |

| 6 | Dry all components completely | Prevent Corrosion |

| 7 | Store in a dust-free container | Long-Term Protection |

Ensure your spectroelectrochemical experiments are safe, accurate, and reproducible.

Proper cell maintenance is critical for data integrity and equipment longevity. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools your laboratory needs for success.

Let our experts help you optimize your lab workflows. Contact KINTEK today to discuss your specific requirements and discover how our solutions can enhance your research.

Visual Guide

Related Products

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What preparation steps are required before initiating an experiment with the thin-layer spectroelectrochemical cell?

- What general precautions should be taken when using a thin-layer spectroelectrochemical cell? Ensure Accurate Results and Equipment Safety

- Which electrode types are compatible with thin-layer spectroelectrochemical cells? Optimize Your Hardware Fit

- What are the key maintenance and handling procedures for a thin-layer spectroelectrochemical cell? Protect Your Sensitive Lab Equipment

- For what types of systems, temperature ranges, and sealing configurations is the thin-layer spectroelectrochemical cell designed? Ideal for Aqueous and Non-Aqueous Analysis