Before any experiment, a gold disc electrode requires a meticulous multi-step pretreatment process to ensure a clean, reproducible, and electrochemically active surface. The standard procedure involves a physical inspection, mechanical polishing with progressively finer alumina powder to create a mirror-like finish, and a final, thorough cleaning with deionized water and organic solvents to remove all residues. This protocol is not merely a suggestion; it is a fundamental requirement for obtaining accurate and reliable electrochemical data.

The core objective of pretreating a gold electrode is to remove surface oxides, adsorbed contaminants, and physical imperfections from previous use. A consistent and thorough pretreatment protocol is the single most important factor in ensuring the reproducibility of your electrochemical measurements.

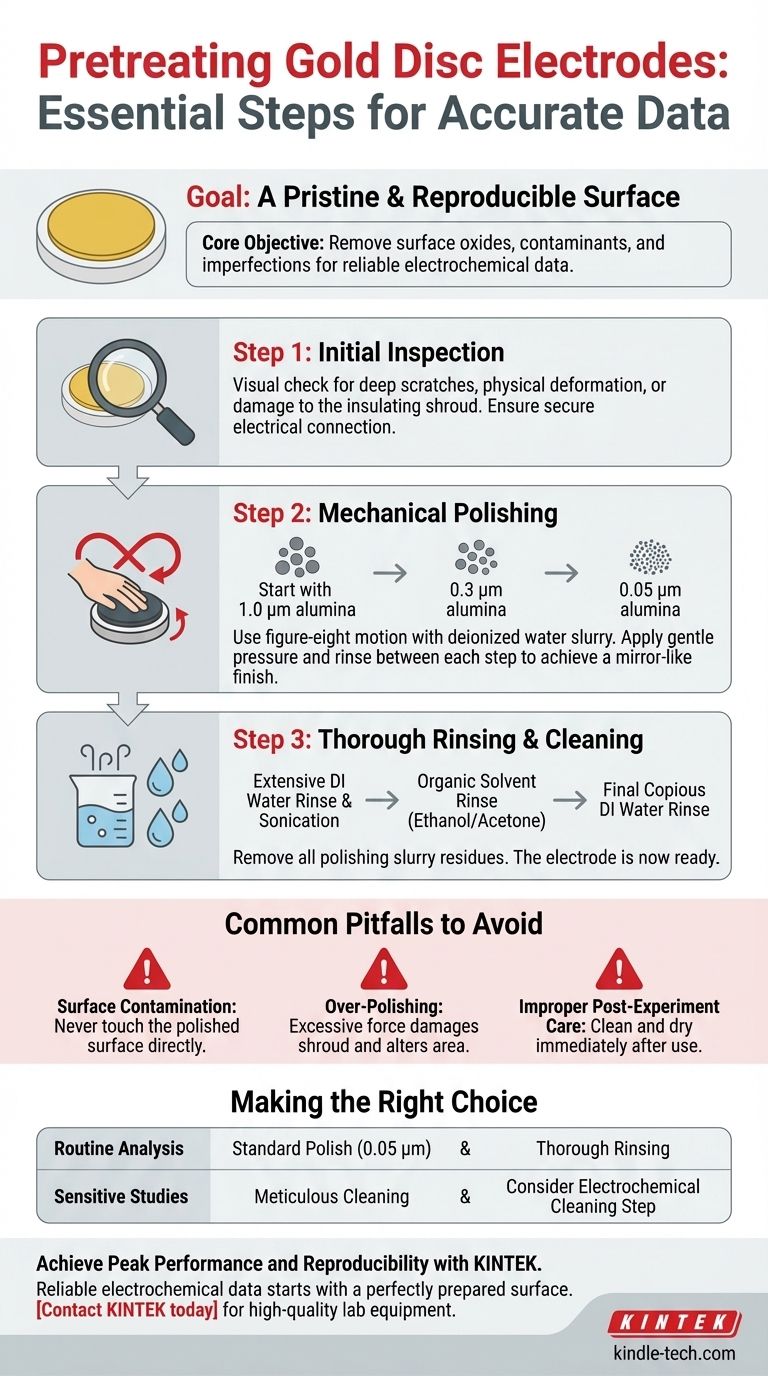

The Goal: A Pristine and Reproducible Surface

In electrochemistry, all reactions occur at the electrode-electrolyte interface. The condition of this interface dictates the accuracy, sensitivity, and reproducibility of your results.

Why Pretreatment is Non-Negotiable

An untreated gold surface is never truly "clean." It is typically covered by a layer of atmospheric contaminants, organic molecules, and a thin film of gold oxide. These layers can block or alter the electron transfer processes you intend to study, leading to distorted data, shifted potentials, and unreliable conclusions.

The "Electrochemical Fingerprint"

A properly prepared electrode has a known and repeatable electrochemical behavior in a standard solution (e.g., the characteristic oxidation and reduction peaks of gold in sulfuric acid). This "fingerprint" confirms the surface is clean and ready for your experiment. Without proper pretreatment, this baseline is inconsistent.

The Standard Pretreatment Protocol

Follow these steps methodically to prepare your gold disc electrode. The key is consistency; perform the procedure the same way before every experiment.

Step 1: Initial Inspection

Before any polishing, perform a quick visual check. Look for deep scratches, physical deformation of the gold disc, or damage to the insulating PEEK or Teflon shroud surrounding it. Ensure the electrical connection is secure. Gross physical damage may render the electrode unusable.

Step 2: Mechanical Polishing

The goal of polishing is to physically remove the contaminated surface layer and create a smooth, mirror-like finish.

Place a small amount of polishing powder on a polishing cloth or pad. Start with a coarser grit, such as 1.0 µm alumina, and moisten the pad with deionized water to form a slurry.

Hold the electrode perpendicular to the pad and polish the surface using a figure-eight motion. Apply gentle, consistent pressure.

After a minute of polishing, rinse the electrode and the polishing pad thoroughly. Repeat the process with progressively finer polishing powders, such as 0.3 µm and finally 0.05 µm alumina, rinsing meticulously between each step. The final surface should be highly reflective with no visible scratches.

Step 3: Thorough Rinsing and Cleaning

This step is critical for removing all traces of the polishing slurry.

First, rinse the electrode extensively with deionized water. Sonicating the electrode in a beaker of deionized water for a few minutes is a highly effective method for dislodging fine alumina particles from the surface.

Next, rinse with an organic solvent like ethanol or acetone to remove any organic contaminants. Follow this with a final, copious rinse with deionized water to remove the solvent. The electrode is now ready for your experiment.

Common Pitfalls to Avoid

Even a standard procedure can fail if not executed with care. Being aware of common mistakes is key to achieving a consistently clean surface.

Avoiding Surface Contamination

The most common source of contamination is your own hands. Never touch the polished electrode surface directly. Handle it only by the insulating body. Ensure all beakers, tweezers, and solutions used during preparation are scrupulously clean.

The Risk of Over-Polishing

While polishing is necessary, excessive or overly aggressive polishing can damage the electrode. It can wear down the edges of the insulating shroud, compromising the seal and altering the defined electrode area. Use gentle pressure and let the polishing powder do the work.

Improper Post-Experiment Care

Your pretreatment for the next experiment begins the moment the last one ends. Immediately after use, remove the electrode from the electrolyte, rinse it thoroughly with deionized water, and dry it with filter paper. Storing a clean electrode is far better than letting reactants dry on its surface.

Making the Right Choice for Your Goal

While the core protocol is universal, the level of rigor may vary slightly depending on your application.

- If your primary focus is routine analysis (e.g., basic cyclic voltammetry): A consistent mechanical polish (0.05 µm alumina) followed by thorough rinsing is typically sufficient to achieve reproducible results.

- If your primary focus is sensitive surface studies (e.g., self-assembled monolayers, trace analysis): Meticulous cleaning is paramount. After the standard mechanical polish, consider adding an electrochemical cleaning step (e.g., cycling the potential in acid) to ensure the highest possible surface purity.

Ultimately, a well-defined and consistently executed pretreatment protocol is the foundation upon which reliable electrochemical data is built.

Summary Table:

| Step | Purpose | Key Details |

|---|---|---|

| 1. Initial Inspection | Check for physical damage | Visual check for scratches, deformation, or damage to the insulating shroud. |

| 2. Mechanical Polishing | Remove contaminants and create a smooth surface | Use a figure-eight motion with progressively finer alumina powder (1.0 µm → 0.3 µm → 0.05 µm). |

| 3. Thorough Rinsing & Cleaning | Remove all polishing residues | Rinse with deionized water, sonicate, then rinse with ethanol/acetone, followed by a final water rinse. |

Achieve Peak Performance and Reproducibility in Your Lab

Struggling with inconsistent electrochemical data? The precision of your results starts with a perfectly prepared electrode surface. KINTEK specializes in high-quality lab equipment and consumables, including the reliable materials needed for meticulous electrode pretreatment. Our products are designed to support researchers in achieving the clean, reproducible surfaces essential for accurate analysis.

Let our experts help you optimize your workflow. Contact KINTEK today to discuss your laboratory needs and discover how our solutions can enhance the reliability of your electrochemical measurements.

Visual Guide

Related Products

- Gold Disc Electrode

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Electron Beam Evaporation Coating Gold Plating Tungsten Molybdenum Crucible for Evaporation

- Warm Isostatic Press for Solid State Battery Research

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

People Also Ask

- What is the typical role of a gold disc electrode in an electrochemical setup? Your Guide to a Precise Working Electrode

- What are the performance characteristics of a gold plate electrode? Unmatched Stability for Reliable Data

- What is the proper post-treatment and storage procedure for a gold disc electrode? Ensure Reliable Electrochemical Data

- How should a gold disc electrode be handled during an experiment? Ensure Accurate Electrochemical Measurements

- What are the key precautions for a gold disc electrode? Ensure Accurate Results & Long Lifespan