At its core, carburizing is a heat treatment process that hardens the surface of low-carbon steel components, creating a wear-resistant exterior while maintaining a softer, tougher interior. Its primary advantages are significantly improved fatigue strength and surface hardness. The main disadvantages involve process complexity, potential environmental and safety liabilities, and costs that vary significantly depending on the specific method used.

The decision to use carburizing is not just a materials science question; it's a manufacturing strategy question. The right choice depends on balancing the high performance it delivers against the total cost, which includes capital equipment, operational complexity, and post-processing requirements.

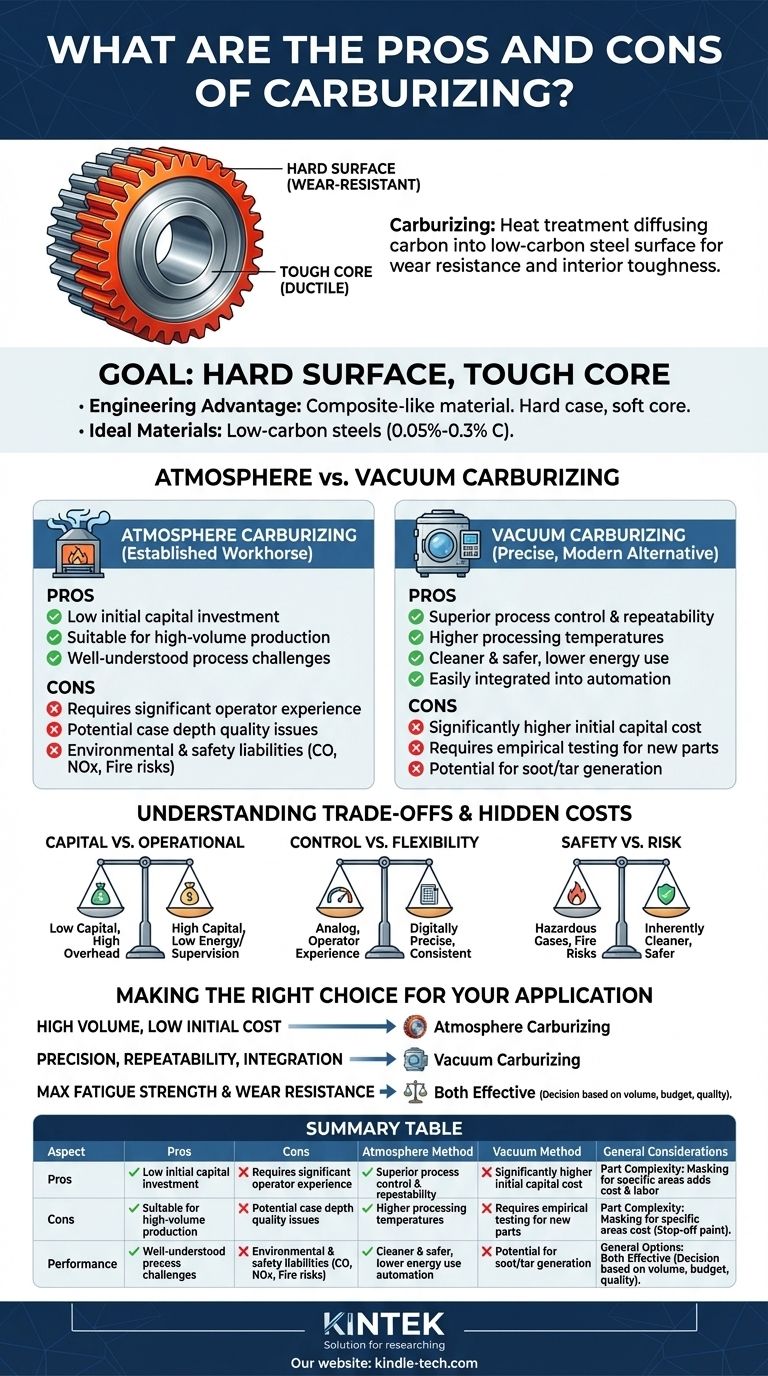

The Goal of Carburizing: Hard Surface, Tough Core

What is Carburizing?

Carburizing is a case-hardening process that involves diffusing carbon atoms into the surface of a low-carbon steel part. By heating the steel in a carbon-rich environment, the surface layer absorbs carbon, allowing it to become significantly harder after quenching.

The Engineering Advantage

This process creates a composite-like material. The hard, high-carbon case provides excellent resistance to wear, abrasion, and fatigue failure. Meanwhile, the softer, low-carbon core retains its toughness and ductility, allowing the component to absorb shock and resist catastrophic fracture.

Ideal Materials

Carburizing is specifically designed for low-carbon steels, typically with a carbon content ranging from 0.05% to 0.3%. These steels have the toughness desired for the core but lack the inherent hardness for demanding surface applications.

Comparing the Primary Methods: Atmosphere vs. Vacuum

The choice of carburizing method is the most critical decision, as it dictates cost, precision, and operational complexity.

Atmosphere Carburizing: The Established Workhorse

This traditional method involves heating parts in a furnace filled with a carbon-rich endothermic gas, most often containing carbon monoxide (CO).

The primary advantages are its low initial capital investment and its suitability for high-volume production. Because it has been used for decades, its process challenges are well-understood.

However, it requires significant operator experience to achieve repeatable results. Equipment must be carefully conditioned if shut down, and the process can create case depth quality issues that require larger material allowances for post-machining.

Vacuum Carburizing: The Precise, Modern Alternative

Also known as low-pressure carburizing, this method places parts in a vacuum before introducing a hydrocarbon gas (like acetylene or propane) at high temperatures.

Its key advantages are superior process control and repeatability, often managed by precise computer models. It allows for higher processing temperatures, is easily integrated into automated manufacturing cells, and only consumes energy when a cycle is running.

The main drawback is a significantly higher initial capital cost. While highly automated, it still requires empirical testing to optimize cycles for new parts and can produce soot or tar if gas parameters are not carefully controlled.

Understanding the Trade-offs and Hidden Costs

A simple "pro vs. con" list is insufficient. The real decision lies in understanding the competing factors of cost, quality, and safety.

Capital Investment vs. Operational Overhead

Atmosphere carburizing is cheaper to set up but can be more expensive to run due to the need for constant gas generation, process monitoring, and experienced operators.

Vacuum carburizing has a high barrier to entry due to equipment cost but offers lower energy consumption and can be run with less direct supervision once programmed.

Process Control vs. Flexibility

Vacuum carburizing provides digitally precise control over case depth and carbon profile, resulting in higher part-to-part consistency.

Atmosphere carburizing is a well-established but more "analog" process. It relies heavily on the empirical knowledge of technicians to troubleshoot and maintain quality.

Environmental and Safety Liabilities

This is a critical disadvantage for atmosphere carburizing. It requires constant monitoring of hazardous gases like CO and NOx, disposal of contaminated quench oils, and managing significant fire risks from combustible gases.

Vacuum carburizing is inherently cleaner and safer, largely eliminating the risk of toxic gas exposure and open flames.

Part Complexity and Masking

For both methods, hardening only specific areas of a part can become costly and labor-intensive. It requires applying a special "stop-off" paint to prevent carbon diffusion, which adds a manual step and increases the total cost per part. In such cases, induction hardening might be a more efficient alternative.

Making the Right Choice for Your Application

To select the appropriate method, you must align the process capabilities with your primary manufacturing goal.

- If your primary focus is high-volume production with minimal initial investment: Atmosphere carburizing is the proven, cost-effective choice, provided you can manage the environmental and operational overhead.

- If your primary focus is precision, repeatability, and integration into a clean manufacturing cell: Vacuum carburizing is superior, despite its higher upfront cost, due to its precise control and lower environmental impact.

- If your primary focus is maximizing fatigue strength and wear resistance on low-carbon steel: Both methods are highly effective, and the decision will pivot entirely on your production volume, budget, and quality consistency requirements.

Understanding these fundamental trade-offs empowers you to select the hardening process that aligns not just with your material specifications, but with your entire manufacturing strategy.

Summary Table:

| Aspect | Pros | Cons |

|---|---|---|

| Performance | Hard, wear-resistant surface; Tough, ductile core; High fatigue strength | Only suitable for low-carbon steels (0.05-0.3% C) |

| Atmosphere Method | Lower initial cost; Well-established for high volume | Requires expert operators; Environmental/safety risks (CO, NOx); Higher operational overhead |

| Vacuum Method | Superior precision & repeatability; Cleaner & safer; Lower energy use when idle | High initial capital cost; Requires cycle optimization for new parts |

| General Considerations | Creates a composite-like material ideal for demanding applications | Complex process; Potential for soot/tar; Stop-off masking adds cost and labor |

Ready to optimize your component's performance with the right heat treatment?

At KINTEK, we specialize in providing the lab equipment and consumables needed to support advanced processes like carburizing. Whether you're developing new materials or ensuring quality control in manufacturing, our solutions help you achieve precise, repeatable results.

Let's discuss how we can support your laboratory's needs. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- What is an example of an inert atmosphere? Discover the Best Gas for Your Process

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2