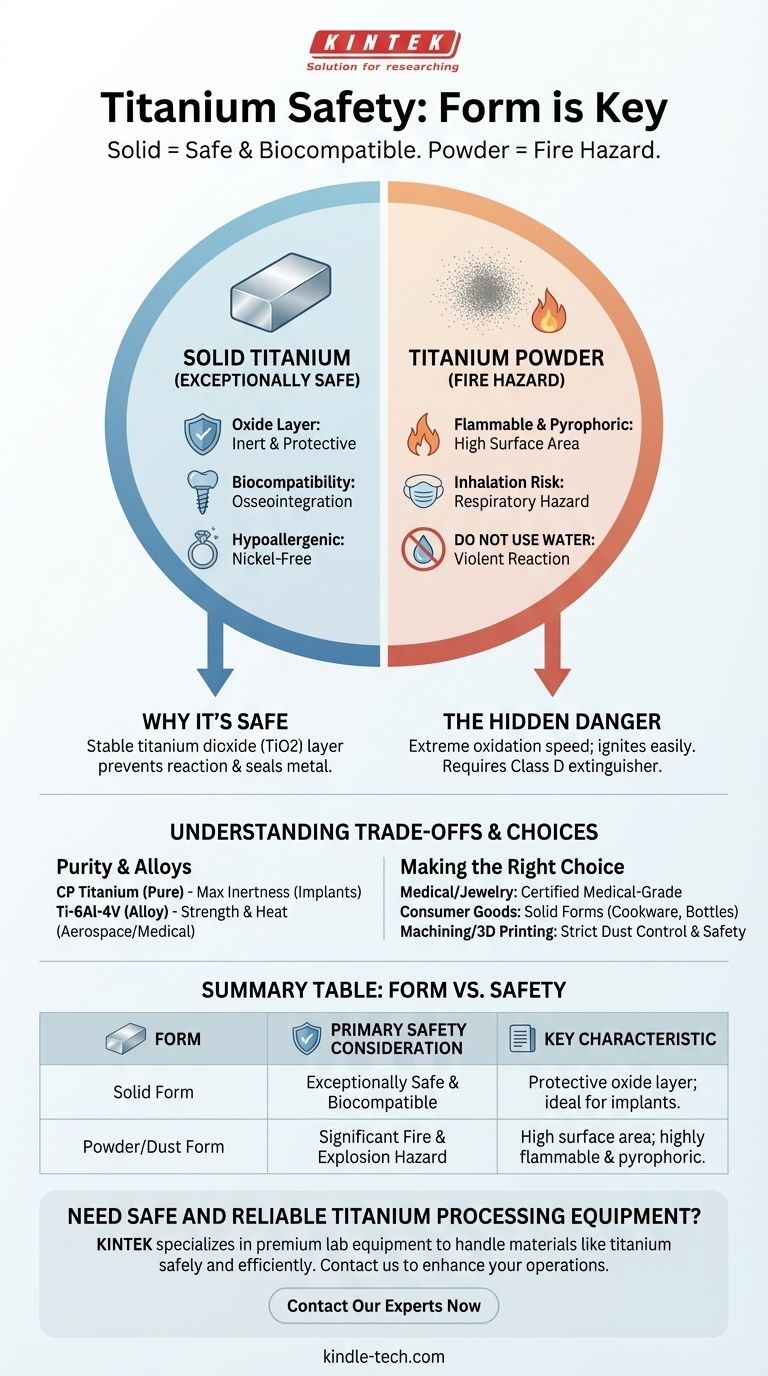

In its solid, finished form, titanium is one of the safest and most biocompatible metals available. It is prized for its inertness and resistance to corrosion, making it an ideal material for medical implants, jewelry, and consumer products. However, the safety profile of titanium changes dramatically when it is in a fine powder or dust form, where it becomes a significant fire hazard.

The safety of titanium is not absolute; it is entirely dependent on its physical form. While solid titanium is exceptionally inert and safe for everything from medical implants to consumer goods, titanium powder or dust is a significant and dangerous fire hazard.

Why Solid Titanium Is Exceptionally Safe

The excellent safety record of solid titanium is not an accident; it is a direct result of its fundamental chemical properties. When exposed to oxygen in the air or water, it instantly forms a thin, stable, and highly protective layer of oxide.

The Power of the Oxide Layer

This passive layer of titanium dioxide (TiO2) is the key to its safety. The layer is incredibly tenacious, self-healing, and chemically inert, meaning it does not react with its environment.

This oxide film effectively seals the pure titanium metal from the outside world, preventing it from leaching into the body or reacting with bodily fluids.

Superior Biocompatibility

Because of this inert oxide layer, the human body does not recognize solid titanium as a foreign object. This allows for osseointegration, where human bone can grow directly onto the surface of a titanium implant.

This property makes it the gold standard for dental implants, artificial joints, and plates or screws used to set broken bones.

Hypoallergenic Properties

Many metal allergies, particularly to nickel, are a common problem with jewelry and implants made from stainless steel or other alloys.

Commercially pure titanium is free from nickel and other common sensitizing agents, making it an excellent hypoallergenic choice for anyone with sensitive skin or metal allergies.

The Hidden Danger: Titanium in Powder or Dust Form

The safety equation flips entirely when dealing with fine titanium particles, such as dust from grinding or machining, or manufactured powder used in 3D printing. The same property that makes it stable—its high affinity for oxygen—makes its powder form dangerous.

Extreme Flammable & Pyrophoric Risk

A powder has an incredibly high surface-area-to-volume ratio. This massive surface area allows the titanium to oxidize (burn) with extreme speed and intensity if ignited.

Titanium dust is highly flammable and can be ignited by a simple spark, static discharge, or excessive heat. In certain conditions, fine titanium powder is pyrophoric, meaning it can spontaneously combust upon contact with air.

Inhalation and Handling Concerns

While solid titanium is non-toxic, inhaling any fine metallic dust is a respiratory hazard that can cause lung irritation. Workshop dust must be managed with proper ventilation and personal protective equipment (PPE).

Water should never be used to extinguish a titanium fire, as it can dissociate the water into hydrogen and oxygen, leading to a violent explosion. Only a Class D fire extinguisher is suitable.

Understanding the Trade-offs: Purity and Alloys

Not all titanium is created equal. The distinction between pure titanium and its alloys is an important safety and performance consideration.

Commercially Pure (CP) Titanium

Commercially Pure (CP) titanium is unalloyed and graded based on its allowable oxygen and iron content. Grade 1 and 2 are the most pure and ductile.

Because of its purity and proven biocompatibility, CP titanium is often the preferred choice for dental and surgical implants where maximum inertness is the primary goal.

Common Titanium Alloys

Alloys are created to enhance properties like strength and heat resistance. The most common is Ti-6Al-4V (Grade 5), which contains 6% aluminum and 4% vanadium.

This alloy is widely used in aerospace and is also certified for many medical applications. While there have been some historical scientific discussions about the long-term effects of vanadium, it is considered safe and stable within the alloy matrix for approved medical uses.

Making the Right Choice for Your Goal

Your application dictates which safety considerations are most relevant.

- If your primary focus is medical implants or body-contact jewelry: Use only certified medical-grade titanium (CP Grade 2 or Ti-6Al-4V) from a reputable supplier to ensure purity and safety.

- If your primary focus is consumer goods like cookware or water bottles: Solid titanium products are exceptionally safe, non-toxic, and present no chemical leaching concerns.

- If your primary focus is machining, 3D printing, or processing titanium: The dominant risk is fire and explosion from dust. You must implement strict dust control, ventilation, grounding, and use Class D fire suppression systems.

By understanding that titanium's safety is defined by its form and application, you can leverage its remarkable properties with confidence and control.

Summary Table:

| Form of Titanium | Primary Safety Consideration | Key Characteristic |

|---|---|---|

| Solid Form | Exceptionally Safe & Biocompatible | Protective oxide layer prevents reaction; ideal for implants and consumer goods. |

| Powder/Dust Form | Significant Fire & Explosion Hazard | High surface area makes it highly flammable and pyrophoric. |

Need Safe and Reliable Titanium Processing Equipment?

Whether you are developing medical implants or manufacturing consumer goods, managing the risks associated with titanium is critical. KINTEK specializes in premium lab equipment and consumables, serving the precise needs of laboratories and production facilities.

We provide solutions that help you handle materials like titanium safely and efficiently. Contact us today to discuss how our equipment can enhance the safety and productivity of your operations.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- How can you improve corrosion resistance? Extend Equipment Life with Proven Strategies

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges