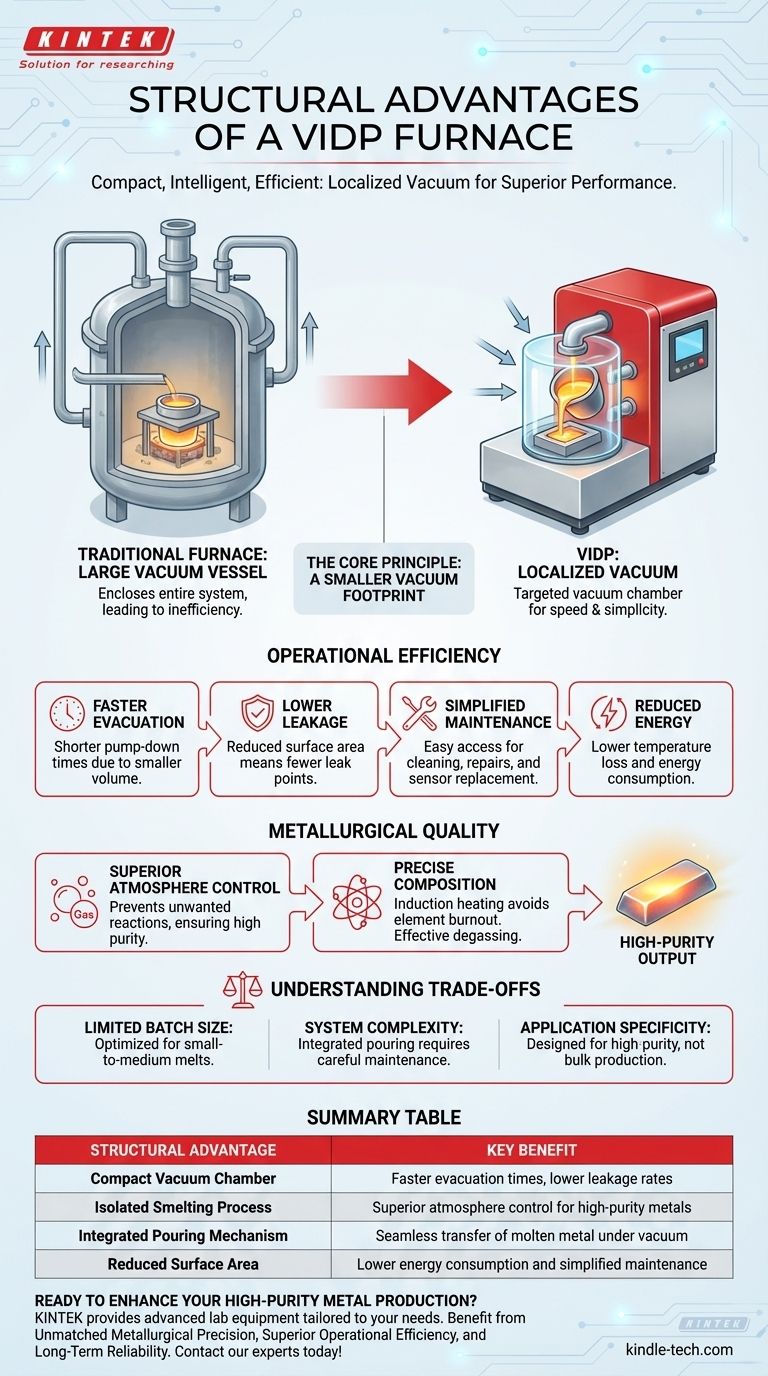

The primary structural advantage of a Vacuum Induction Degassing Pouring (VIDP) furnace is its compact and intelligent design. Unlike traditional furnaces that enclose the entire system in a large vacuum vessel, a VIDP furnace localizes the vacuum to a small chamber around the smelting area, leading to significant gains in efficiency and operational simplicity.

By enclosing only the essential smelting components in a minimized vacuum chamber, the VIDP design directly translates its compact structure into faster cycle times, lower operational costs, and simplified maintenance routines.

The Core Design Principle: A Smaller Vacuum Footprint

The VIDP furnace's effectiveness stems from a simple but powerful structural choice: reducing the volume that needs to be held under vacuum. This is the foundation for its primary advantages.

Isolating the Smelting Process

A VIDP furnace features a small, dedicated vacuum chamber that contains only the smelting crucible. This targeted approach avoids the need to evacuate a massive, all-encompassing chamber.

Integrated Pouring Mechanism

Pouring is conducted through a specialized diversion groove. This allows the molten metal to be transferred to the mold while maintaining the vacuum integrity of the smelting chamber, creating a seamless and controlled process.

Translating Structure into Operational Efficiency

This compact design has a direct and measurable impact on day-to-day furnace operations, making the system faster, more reliable, and more economical.

Faster Evacuation and Lower Leakage

A smaller chamber volume means there is significantly less air to pump out, resulting in shorter evacuation times.

Furthermore, the reduced surface area of the vacuum chamber means there are fewer potential points for leaks, leading to a lower overall leakage rate and a more stable vacuum.

Simplified Maintenance and Repairs

The small, accessible nature of the vacuum chamber makes tasks like leak detection, internal cleaning, and repairs much faster and easier to perform.

Even routine tasks like replacing a thermocouple are simplified due to the compact and accessible structure.

Reduced Energy Consumption

With a smaller volume and less exposed surface area, the furnace experiences lower temperature loss. This efficiency means less energy is required to maintain the target melting temperature, contributing to better economy.

Impact on Metallurgical Quality

The structural design isn't just about efficiency; it directly enhances the quality and purity of the final product.

Superior Atmosphere Control

The small specific surface area of the melt pool makes it much easier to control the atmosphere during the process, preventing unwanted reactions with residual gases.

Precise Composition and Purity

VIDP technology uses induction heating, which means there is no arc or extreme high-temperature zone. This results in less burnout of sensitive alloying elements.

This precise control, combined with the high-quality vacuum, facilitates the effective removal of impurities through decarburization, deoxidation, and dehydrogenation for extremely low gas content.

Understanding the Trade-offs

While the compact design provides numerous benefits, it's important to recognize the potential limitations inherent in this specialized structure.

Batch Size and Throughput

The very compactness that makes the VIDP efficient can also be a limiting factor for maximum batch size. These systems are typically optimized for small-to-medium-sized melts, not large-scale bulk production.

System Complexity

While individual components are easier to access, the integrated pouring system and specialized seals can introduce a degree of mechanical complexity. Proper maintenance of these components is critical for reliable operation.

Application Specificity

The VIDP furnace is a highly specialized piece of equipment designed for producing high-purity metals. Its design may be less flexible for general-purpose melting applications where a high vacuum is not the primary requirement.

Making the Right Choice for Your Goal

The structural advantages of a VIDP furnace make it an ideal choice for specific, high-value applications.

- If your primary focus is high-purity alloys and special steels: The VIDP’s superior atmosphere control and degassing capabilities provide unmatched metallurgical precision.

- If your primary focus is operational efficiency and rapid cycling: The short evacuation times and simplified maintenance deliver faster turnaround and lower operating costs.

- If your primary focus is large-scale bulk production: You should carefully evaluate if the batch size constraints of a VIDP system align with your required throughput.

Ultimately, the VIDP furnace's intelligent structure directly connects a smaller physical footprint to superior operational performance and product quality.

Summary Table:

| Structural Advantage | Key Benefit |

|---|---|

| Compact Vacuum Chamber | Faster evacuation times, lower leakage rates |

| Isolated Smelting Process | Superior atmosphere control for high-purity metals |

| Integrated Pouring Mechanism | Seamless transfer of molten metal under vacuum |

| Reduced Surface Area | Lower energy consumption and simplified maintenance |

Ready to enhance your high-purity metal production?

The structural intelligence of a VIDP furnace directly translates to operational excellence. At KINTEK, we specialize in providing advanced lab equipment, including vacuum induction melting solutions, tailored to the precise needs of laboratories and R&D facilities.

Our expertise ensures you get a system that delivers:

- Unmatched Metallurgical Precision: Achieve extremely low gas content and precise alloy composition.

- Superior Operational Efficiency: Benefit from faster cycle times and reduced energy costs.

- Long-Term Reliability: Count on simplified maintenance and dedicated support.

Let's discuss how a VIDP furnace can be the cornerstone of your research and development. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is a high-vacuum environment essential for sintering Cu-Ni-W alloys? Achieve Peak Thermal Conductivity

- How does a vacuum hot press furnace contribute to high-density Cr-50 wt% Si alloys? Achieve Superior Densification

- Why is a high vacuum preferred over argon for sintering VC/Cu composites? Achieve Superior Wetting and Bond Strength

- Why is it essential to maintain a high vacuum state during hot press sintering? Optimize SiCp/2024Al Quality