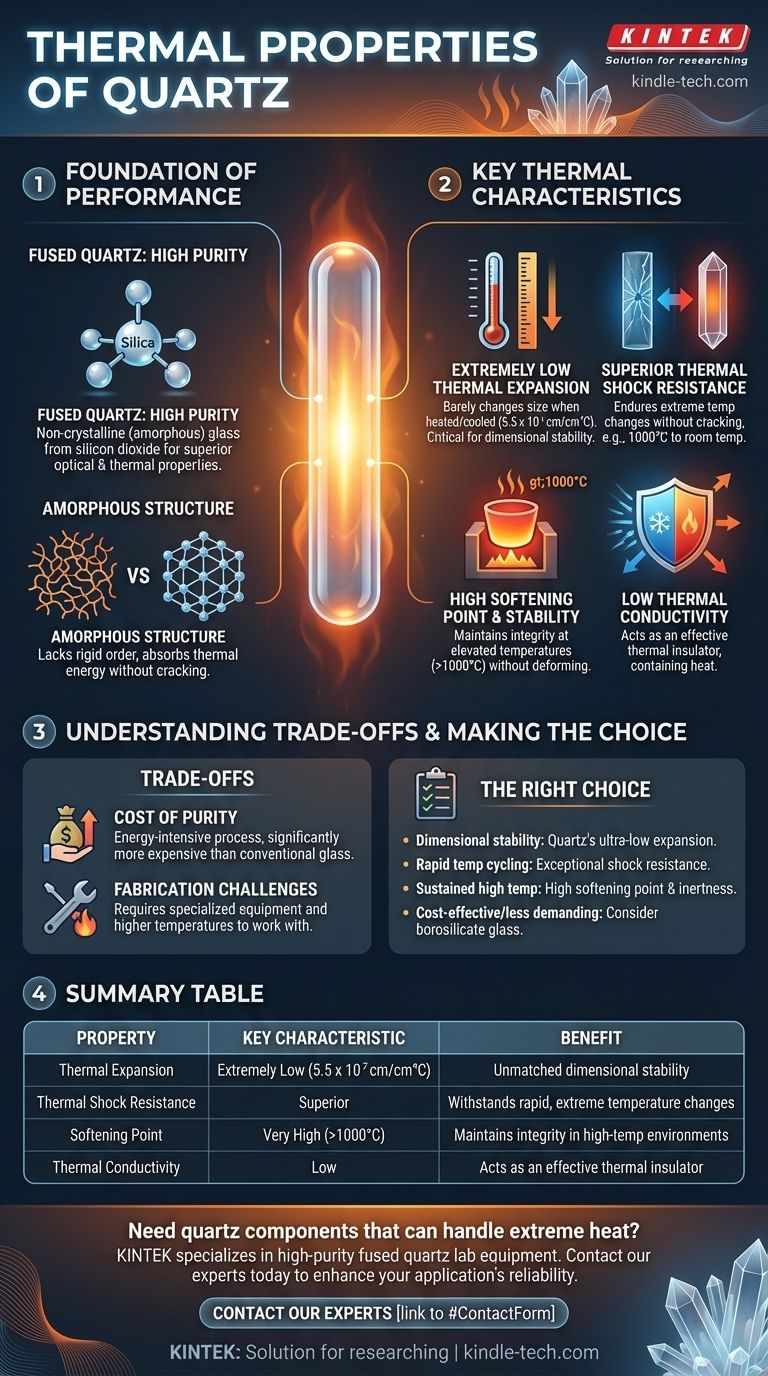

At its core, quartz possesses exceptional thermal properties, particularly in its high-purity form known as fused quartz. This material is defined by an extremely low coefficient of thermal expansion (5.5 x 10⁻⁷ cm/cm°C), superior resistance to thermal shock, and a very high softening temperature, allowing it to maintain its structural and optical integrity in extreme temperature environments where conventional glass would fail.

The defining thermal characteristic of fused quartz is its stability. Its unique combination of low thermal expansion, high thermal shock resistance, and a high softening point stems directly from its high-purity amorphous silicon dioxide structure, making it a premier material for demanding thermal applications.

The Foundation of Quartz's Performance

The remarkable thermal properties of quartz are not accidental; they are a direct result of its fundamental chemical purity and atomic structure.

Why "Fused Quartz" is the Key Term

When discussing these properties, we are almost always referring to fused quartz. This is a non-crystalline (amorphous) glass made from silicon dioxide in a very high state of purity.

This high purity is the primary reason its optical and thermal properties are far superior to those of other glass types, such as borosilicate or soda-lime glass.

Impact of its Amorphous Structure

Unlike crystalline quartz, the amorphous structure of fused quartz lacks rigid, long-range order. This internal structure is key to its ability to absorb thermal energy without generating the significant internal stresses that cause other materials to crack or deform.

Key Thermal Characteristics Explained

The unique structure of fused quartz gives rise to a set of highly desirable thermal behaviors that make it invaluable for science and industry.

Extremely Low Thermal Expansion

Fused quartz barely changes in size when heated or cooled. Its low coefficient of thermal expansion means it exhibits incredible dimensional stability across a wide range of temperatures.

This property is critical for applications like telescope mirrors, metrology instruments, and semiconductor processing, where even microscopic changes in shape can compromise performance.

Superior Thermal Shock Resistance

The low thermal expansion directly leads to world-class thermal shock resistance. The material can endure extreme temperature changes without cracking.

It's common for quartz tubes to be heated to over 1000°C and then rapidly cooled to room temperature without any damage, a process that would shatter nearly any other type of glass.

High Softening Point and Temperature Stability

Fused quartz has a very high softening temperature and elevated thermal resistance.

It can be used continuously at temperatures exceeding 1000°C for extended periods without deforming, melting, or changing color, making it ideal for high-temperature furnace tubes, crucibles, and optical components used in UV lamps.

Low Thermal Conductivity

Quartz is a poor conductor of heat, meaning it is a good thermal insulator. It resists the transfer of heat from one side of the material to the other.

This property is useful for applications that require heat to be contained or for protecting sensitive components from a nearby heat source.

Understanding the Trade-offs

While its thermal properties are exceptional, fused quartz is not the default choice for every application. Its unique advantages come with practical considerations.

The Cost of Purity

The manufacturing process required to achieve the high purity of fused quartz is energy-intensive and complex. Consequently, it is significantly more expensive than conventional glasses.

Fabrication Challenges

The same high softening point that makes quartz so useful also makes it more difficult to work with. Fabricating, molding, and shaping quartz components requires specialized equipment and higher temperatures compared to standard glassworking.

Making the Right Choice for Your Application

Selecting a material requires balancing performance needs with practical constraints. Fused quartz is the definitive choice when thermal stability is non-negotiable.

- If your primary focus is dimensional stability across a wide temperature range: Quartz's ultra-low thermal expansion is its most critical and defining feature.

- If your primary focus is surviving rapid and extreme temperature cycling: Its exceptional thermal shock resistance makes it the ideal and often only choice.

- If your primary focus is sustained operation in a high-temperature environment: Quartz's high softening point and chemical inertness provide reliable performance.

- If your primary focus is cost-effectiveness for a less demanding thermal environment: A different material, such as borosilicate glass, may offer a more practical trade-off.

Understanding these distinct thermal properties empowers you to select the right material for the most demanding technical challenges.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Thermal Expansion | Extremely Low (5.5 x 10⁻⁷ cm/cm°C) | Unmatched dimensional stability |

| Thermal Shock Resistance | Superior | Withstands rapid, extreme temperature changes |

| Softening Point | Very High (>1000°C) | Maintains integrity in high-temperature environments |

| Thermal Conductivity | Low | Acts as an effective thermal insulator |

Need quartz components that can handle extreme heat? KINTEK specializes in high-purity fused quartz lab equipment, including furnace tubes, crucibles, and custom components. Our products deliver the critical thermal stability, shock resistance, and high-temperature performance your laboratory demands. Contact our experts today to discuss how our quartz solutions can enhance your application's reliability and performance.

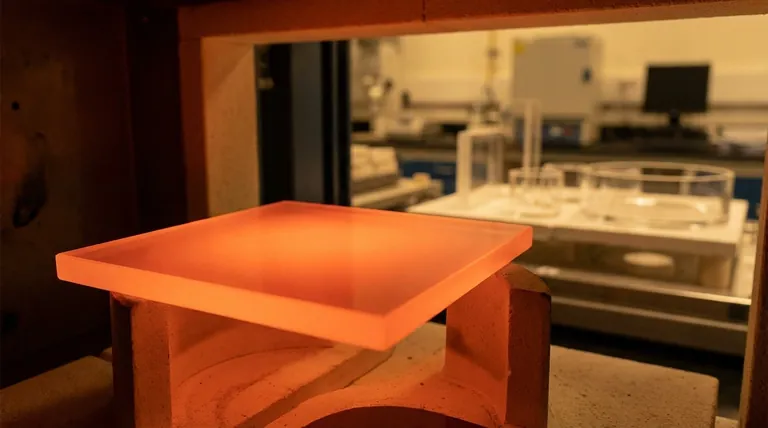

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

People Also Ask

- What temperature does quartz glass melt at? Understanding Its Softening Point and Practical Limits

- What are the uses of quartz glass? Essential for Extreme-Temperature and UV Applications

- What is the working temperature of quartz glass? Master Its High-Temp Limits & Applications

- What is the high temperature of quartz? Key Thresholds for Crystalline vs. Fused Silica

- Does quartz have a high melting point? Discover Its Superior High-Temperature Performance