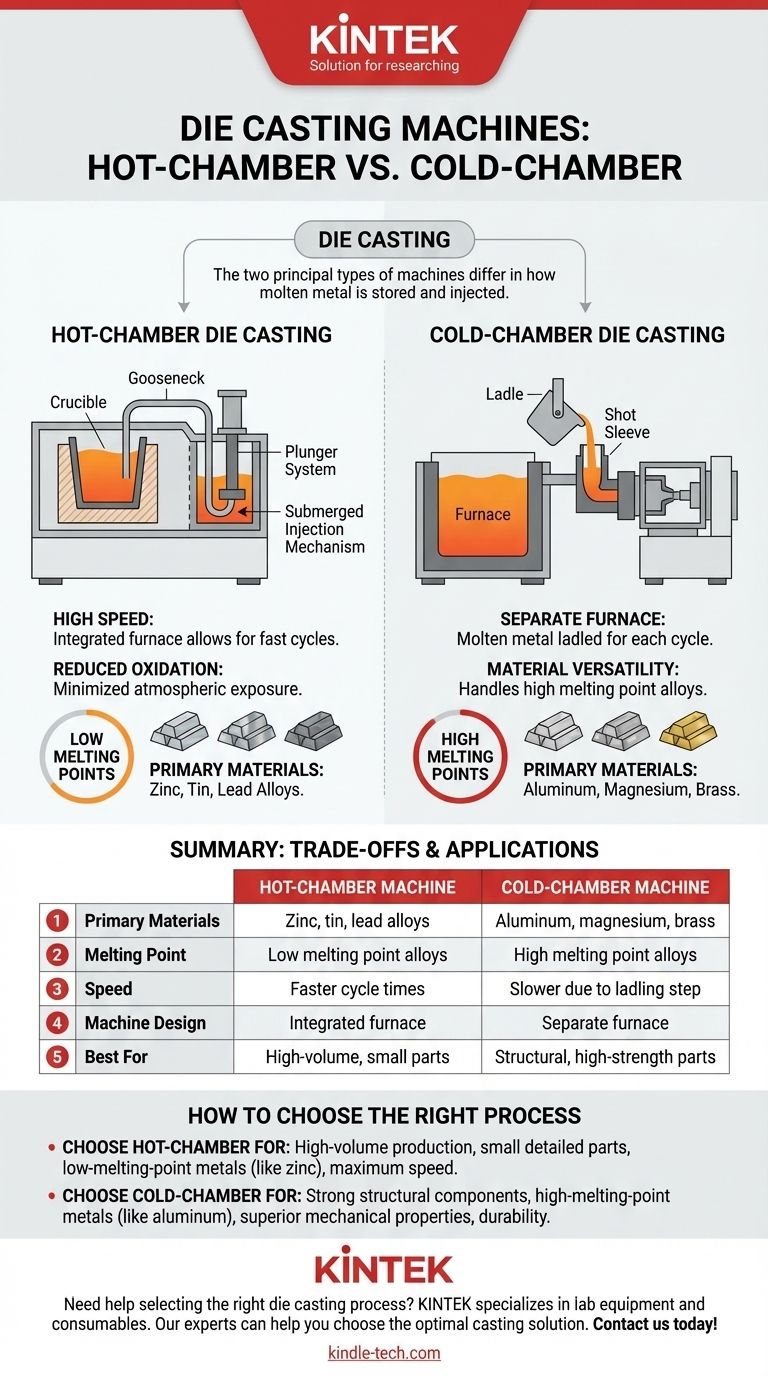

In die casting, the two principal types of machines are the hot-chamber machine and the cold-chamber machine. The fundamental difference between them lies in how molten metal is stored and injected into the mold. Hot-chamber machines contain the furnace as an integral part of the machine, while cold-chamber machines use a separate furnace to melt the metal before it is transferred for injection.

The choice between a hot-chamber and a cold-chamber machine is not a matter of preference, but a technical necessity dictated almost entirely by the melting point and corrosive properties of the alloy you need to cast.

Understanding Hot-Chamber Die Casting

Hot-chamber die casting is a highly efficient process characterized by its integrated design. The injection mechanism is submerged directly in the molten metal bath held within the machine.

The Core Mechanism

In a hot-chamber machine, the furnace is connected to the die via a "gooseneck." A plunger system, immersed in the molten metal, forces a measured amount of metal up through the gooseneck and into the die cavity with each cycle.

Because the metal is already molten within the machine's own reservoir, the injection process is extremely fast and direct.

Key Advantages

The primary advantage of this process is speed. Cycle times for hot-chamber machines are significantly shorter than for cold-chamber machines, as there is no need to transfer metal from an external furnace.

This process also minimizes the metal's exposure to the atmosphere, which can reduce oxidation and improve the final part's consistency.

Primary Applications and Materials

Hot-chamber machines are exclusively used for alloys with low melting points and low corrosivity.

Common materials include zinc, tin, and lead-based alloys. The high heat and corrosive nature of metals like aluminum would quickly damage the machine's submerged injection components.

Understanding Cold-Chamber Die Casting

Cold-chamber die casting is a more robust process designed to handle materials that are unsuitable for hot-chamber machines. Its defining feature is the separation of the furnace from the injection system.

The Core Mechanism

Molten metal is held in a separate furnace. For each cycle, a precise amount of metal is ladled from this furnace and poured into the machine's "shot sleeve."

A hydraulic plunger then advances, sealing the port and forcing the metal into the die cavity under immense pressure.

Key Advantages

The standout advantage is material versatility. This process can cast high-melting-point alloys like aluminum, magnesium, and brass without damaging the machine.

The high injection pressures used in cold-chamber casting also help create parts that are very dense and possess excellent structural integrity, making them suitable for demanding applications.

Primary Applications and Materials

Cold-chamber casting is the standard for producing a vast range of components, from engine blocks and transmission housings to laptop cases and power tools.

Aluminum is by far the most common material used in cold-chamber die casting due to its excellent strength-to-weight ratio.

Understanding the Trade-offs: Hot-Chamber vs. Cold-Chamber

Choosing between these two processes involves a clear set of engineering and economic trade-offs that are directly linked to your project's goals.

Material Compatibility

This is the most critical distinction. If you need to cast aluminum or brass, a cold-chamber machine is your only option. The corrosive properties of these molten metals would destroy the internal gooseneck and plunger of a hot-chamber machine.

Conversely, if you are working with zinc, a hot-chamber machine offers a more efficient and faster process.

Production Speed and Cost

For compatible materials like zinc, hot-chamber casting is significantly faster. With no ladling step, cycle rates can be much higher, which often translates to a lower per-part cost in high-volume production runs.

The extra step of ladling metal makes the cold-chamber process inherently slower.

Part Strength

While both processes produce strong parts, cold-chamber casting is typically used for alloys (like aluminum) with superior mechanical properties. The extremely high pressures used also contribute to creating parts with high density and minimal porosity.

Machine Wear and Maintenance

Hot-chamber machines experience more wear on their injection components (the gooseneck and plunger) because they are constantly immersed in molten metal.

Cold-chamber plungers and sleeves have a longer lifespan as they are only in contact with molten metal for a brief period during each cycle.

How to Choose the Right Process

Your material choice is the primary driver, which in turn defines the application. Use this guide to make your decision.

- If your primary focus is high-volume production of smaller, detailed parts with low-melting-point metals (like zinc): Hot-chamber die casting is the faster and more economical choice.

- If your primary focus is creating strong, structural components from high-melting-point metals (like aluminum): Cold-chamber die casting is the necessary and correct process.

- If your primary focus is maximizing production speed for a compatible alloy: Hot-chamber casting offers the highest cycle rates available.

- If your primary focus is part durability and material strength for demanding applications: Cold-chamber casting with aluminum or magnesium alloys provides superior mechanical properties.

Ultimately, understanding this fundamental division allows you to align your material requirements with the correct manufacturing capability.

Summary Table:

| Feature | Hot-Chamber Machine | Cold-Chamber Machine |

|---|---|---|

| Primary Materials | Zinc, tin, lead alloys | Aluminum, magnesium, brass |

| Melting Point | Low melting point alloys | High melting point alloys |

| Speed | Faster cycle times | Slower due to ladling step |

| Machine Design | Integrated furnace | Separate furnace |

| Best For | High-volume, small parts | Structural, high-strength parts |

Need help selecting the right die casting process for your project? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you choose the optimal casting solution based on your material requirements, production volume, and performance goals. Contact us today to discuss your specific application and get professional guidance!

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does heat treatment affect mechanical properties? A Guide to Optimizing Strength, Toughness, and Durability

- What is magnetron sputtering coating? A High-Performance Thin Film Deposition Process

- Why is biomass a renewable resource? Key Principles for Sustainable Energy

- How do you bond steel to steel without welding? Master Structural Adhesives & Mechanical Fasteners

- What are the types of annealing? Choose the Right Process for Your Metal's Properties

- Where is sintering used? From Traditional Manufacturing to Modern 3D Printing

- What is the difference between an industrial furnace and a laboratory electric furnace? Choose the Right Heating System

- What is the minimum melting-temperature for brazing material? The 450°C Threshold Explained