Brazing filler metals are alloys specifically designed to join components at high temperatures. The most common types are categorized by their primary element and include alloys based on silver, copper, aluminum, nickel, and gold. These materials are selected based on their ability to melt at a temperature lower than the base metals being joined, flow into the joint via capillary action, and create a strong, durable bond upon cooling.

The selection of a brazing filler metal is a critical engineering decision that extends beyond its chemical composition. The ideal choice must balance the filler's melting point, its physical compatibility with the base metals, and the final joint's ability to withstand its intended service conditions.

The Core Principles of Filler Metal Selection

To understand the different types of filler metals, you must first grasp the principles that govern their use. The success of any brazing operation depends on the interaction between the filler metal, the base metals, and the heat applied.

The Melting Point Differential

The fundamental rule of brazing is that the filler metal must have a lower melting point than the base metals being joined. The base metals remain solid throughout the process. The filler metal's melting temperature dictates the minimum temperature required for the brazing operation.

Wettability and Capillary Action

A suitable filler metal must be able to "wet" the surfaces of the base metals. This means it must be able to flow cleanly and adhere to the surfaces rather than beading up. Good wettability allows capillary action to draw the molten filler metal into the tight-fitting gap between the components, ensuring a complete and uniform joint.

Compatibility with Base Metals

The filler metal must be metallurgically compatible with the base metals. This ensures a strong bond is formed and prevents undesirable reactions, such as the formation of brittle intermetallic compounds, which can compromise the joint's integrity.

Common Categories of Brazing Filler Metals

Filler metals are typically classified by their main alloying element. Each category offers a unique set of properties suited for different applications, base materials, and service environments.

Silver-Based Alloys

Often referred to as "silver solder," these are some of the most versatile filler metals. They offer excellent flow characteristics, high strength, and ductility, and can be used to join most ferrous and non-ferrous metals, except for aluminum and magnesium.

Copper-Based Alloys

This category includes pure copper, copper-zinc (brass), and copper-phosphorus alloys. Pure copper is widely used for brazing steel and nickel components in controlled-atmosphere furnaces. Copper-phosphorus alloys are self-fluxing on copper but require a separate flux for copper alloys like brass or bronze.

Aluminum-Silicon Alloys

These filler metals are used exclusively for brazing aluminum base metals. Their melting temperatures are very close to that of the aluminum parts, requiring precise temperature control during the brazing process.

Nickel and Cobalt Alloys

Valued for their high-temperature strength and superior corrosion and oxidation resistance, nickel and cobalt alloys are the standard choice for demanding applications. They are commonly used in aerospace, gas turbines, and medical equipment for joining stainless steels and other high-performance alloys.

Gold and Palladium Alloys

These precious metal alloys provide exceptional corrosion resistance, ductility, and reliability. Due to their high cost, they are reserved for critical applications where joint failure is not an option, such as in advanced electronics, aerospace, and medical implants.

Understanding the Trade-offs and Selection Criteria

Choosing the right filler metal involves evaluating several competing factors. An ideal choice for one application may be entirely unsuitable for another.

Balancing the Melting Point

A filler metal's melting point presents a critical trade-off. If it is too low, the resulting joint may lack the strength to perform at the intended service temperature. If it is too high, you risk heat-treating, distorting, or even melting the base metals.

Mechanical and Physical Properties

The filler metal's coefficient of thermal expansion should be close to that of the base metals. A significant mismatch can induce internal stresses as the joint cools, potentially leading to cracking. The final joint must also meet strength, ductility, and conductivity requirements.

The Service Environment

The filler metal must be able to withstand the conditions it will face in service. This includes resistance to corrosion, oxidation, and chemical attack. A silver-based alloy suitable for general use would fail quickly in a high-temperature, corrosive environment where a nickel-based alloy would excel.

Cost and Manufacturability

Cost is always a factor. Precious metal fillers like gold and palladium are used only when their unique properties are essential. The filler must also be available in a usable form, such as wire, strip, foil, or paste, to suit the manufacturing process.

Making the Right Choice for Your Application

Your final selection will depend entirely on the specific goals of your project.

- If your primary focus is general-purpose joining of steels and copper: Silver-based alloys provide an excellent combination of strength, flow, and versatility.

- If your primary focus is high-temperature strength and corrosion resistance: Nickel-based alloys are the definitive choice for demanding applications in aerospace or industrial manufacturing.

- If your primary focus is joining aluminum components: You must use a specialized aluminum-silicon filler metal designed for compatibility and a narrow melting range.

- If your primary focus is maximum cost-effectiveness for furnace brazing steel: Pure copper is often the most economical and effective solution.

Ultimately, choosing the correct filler metal transforms brazing from a simple joining method into a precise and reliable engineering solution.

Summary Table:

| Filler Metal Type | Primary Alloying Elements | Key Characteristics | Common Applications |

|---|---|---|---|

| Silver-Based | Silver, Copper, Zinc | Excellent flow, high strength, versatile | Joining steels, copper, brass; general-purpose use |

| Copper-Based | Copper, Zinc, Phosphorus | Cost-effective, good strength | Furnace brazing of steel, joining copper alloys |

| Aluminum-Silicon | Aluminum, Silicon | Designed for aluminum, narrow melting range | Heat exchangers, aluminum structures |

| Nickel-Based | Nickel, Chromium, Boron | High-temperature strength, superior corrosion resistance | Aerospace, turbines, medical equipment |

| Gold/Palladium | Gold, Palladium | Exceptional corrosion resistance, high reliability | Critical electronics, medical implants, aerospace |

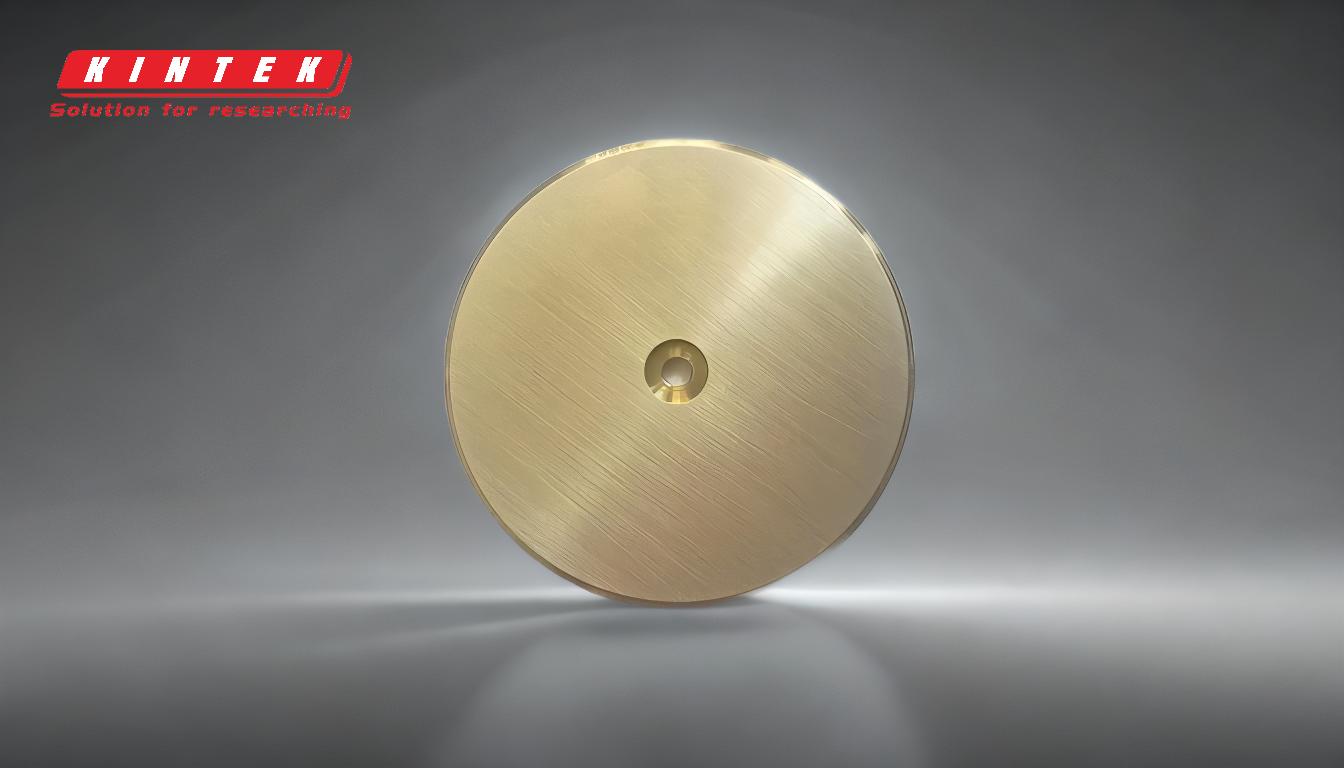

Achieve Perfect Brazed Joints with KINTEK

Selecting the right filler metal is critical to the performance and longevity of your brazed components. The wrong choice can lead to joint failure, corrosion, or inability to withstand service temperatures.

KINTEK specializes in providing high-quality brazing filler metals and expert technical support for your laboratory and manufacturing needs. We help our customers in aerospace, medical, and industrial sectors make the right choice to ensure:

- Optimal Strength and Durability: Filler metals matched to your base materials and service conditions.

- Superior Corrosion and Temperature Resistance: The right alloy for demanding environments.

- Manufacturing Efficiency: Filler metals available in the forms you need—wire, paste, foil, and more.

Don't leave your joint integrity to chance. Let our experts guide you to the perfect brazing solution.

Contact KINTEK today for a consultation and discover how our lab equipment and consumables can enhance your brazing process.