In a professional laboratory, the most common heating apparatus are electric hot plates, heating mantles, water baths, and Bunsen burners. Each is designed for a specific application, balancing the need for temperature control, safety with different chemical types, and compatibility with various glassware shapes.

The core principle of laboratory heating is not just about reaching a target temperature, but about applying heat safely and uniformly. The choice of apparatus depends entirely on the chemical's flammability, the required temperature precision, and the shape of the vessel being heated.

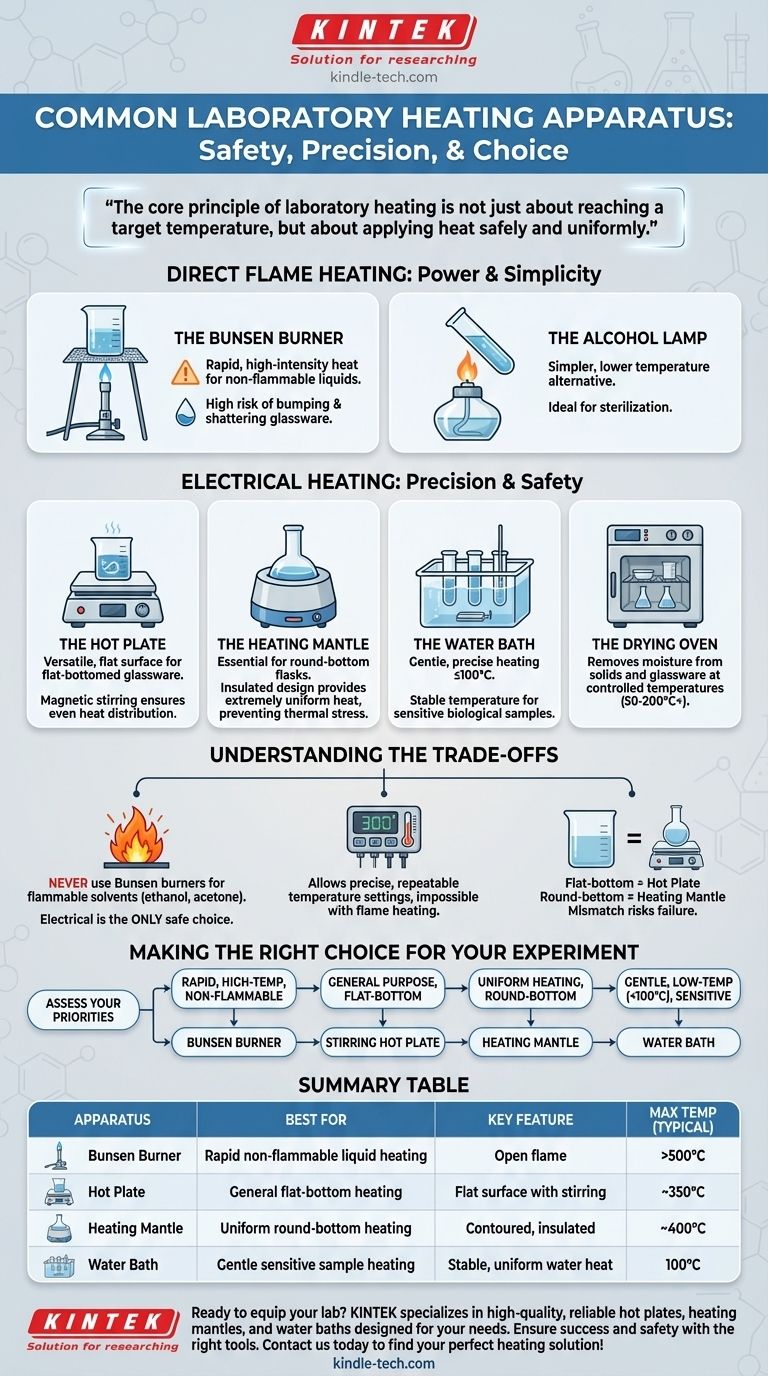

Direct Flame Heating: Power and Simplicity

Open flames provide rapid, high-intensity heat but come with significant safety considerations. They are the oldest method and are still used for specific, simple tasks.

The Bunsen Burner

A Bunsen burner produces a single, open gas flame and is used for very fast heating. It is a common tool for simple procedures like heating non-flammable liquids in a beaker or test tube.

Because the heat is concentrated in a small area, there is a high risk of shattering glassware or causing liquids to boil over violently, a phenomenon known as bumping.

The Alcohol Lamp

An alcohol lamp is a simpler, lower-temperature alternative to a Bunsen burner. It's often used for basic sterilization or when a less intense flame is required.

Electrical Heating: Precision and Safety

Electrical heating methods are the modern standard in most labs because they offer far greater temperature control and eliminate the risks associated with an open flame.

The Hot Plate

The hot plate is arguably the most common and versatile piece of heating equipment. It provides a flat, heated surface ideal for beakers, Erlenmeyer flasks, and other flat-bottomed glassware.

Many models are stirring hot plates, which include a magnetic stirrer. This is critical for distributing heat evenly throughout a liquid and preventing localized overheating at the bottom of the vessel.

The Heating Mantle

A heating mantle is essential for safely heating round-bottom flasks, which are common in organic chemistry. Its insulated, fabric-like cavity cradles the flask, providing extremely uniform heat across its entire surface.

This design prevents the thermal stress that would occur if a round flask were placed on a flat hot plate, significantly reducing the risk of the glass cracking.

The Water Bath

A water bath is used for gentle, precise heating of samples at temperatures at or below 100°C (212°F). The vessel containing the sample is immersed in heated water.

This method provides exceptionally stable and uniform temperature, making it ideal for sensitive biological or enzymatic reactions that can be damaged by overheating.

The Drying Oven

A drying oven is used for removing moisture from solids and glassware at controlled temperatures, typically from 50°C to over 200°C. It functions like a conventional oven but with much higher precision.

Understanding the Trade-offs

Choosing the wrong heating method can ruin an experiment or, worse, create a serious safety hazard. The decision always involves a trade-off between speed, control, and safety.

The Absolute Risk of Open Flames

The number one rule is that Bunsen burners must never be used to heat flammable organic solvents like ethanol, acetone, or ether. The vapors can easily ignite, causing a fire or explosion.

Electrical equipment is the only safe choice when working with flammable materials.

The Precision of Electrical Methods

Electrical apparatus like hot plates and mantles allow for precise, repeatable temperature settings. This control is impossible with a Bunsen burner, where temperature is managed crudely by adjusting the flame height and distance from the vessel.

Matching Glassware to the Apparatus

The shape of your glassware dictates the heating method. A flat-bottomed beaker works perfectly on a hot plate. A round-bottom flask requires a heating mantle for safe and even heating. Forcing a mismatch risks inefficient heating and broken glassware.

Making the Right Choice for Your Experiment

Your specific goal will determine the correct instrument. Before you begin, assess your priorities regarding safety, precision, and the materials you are using.

- If your primary focus is rapid, high-temperature heating of non-flammable liquids (like water): A Bunsen burner is your most direct tool, but always use a wire gauze to diffuse the heat.

- If your primary focus is general-purpose heating of flat-bottomed glassware: A stirring hot plate is the versatile, safe, and standard choice for most applications.

- If your primary focus is uniform heating of a round-bottom flask: A heating mantle is the only appropriate and safe option.

- If your primary focus is gentle, low-temperature heating (below 100°C) for sensitive samples: A water bath provides the most stable and uniform thermal environment.

Selecting the correct heating instrument is the first step toward a safe, repeatable, and successful experiment.

Summary Table:

| Apparatus | Best For | Key Feature | Max Temp (Typical) |

|---|---|---|---|

| Bunsen Burner | Rapid heating of non-flammable liquids | Open flame, high intensity | > 500°C |

| Hot Plate | General heating of flat-bottomed glassware | Flat surface, often with magnetic stirring | ~350°C |

| Heating Mantle | Uniform heating of round-bottom flasks | Contoured, insulated design | ~400°C |

| Water Bath | Gentle heating of sensitive samples | Stable, uniform temperature via water | 100°C |

Ready to equip your lab with the right heating apparatus? KINTEK specializes in high-quality lab equipment, including reliable hot plates, precise heating mantles, and safe water baths designed for your specific laboratory needs. Ensure experiment success and safety with the right tools from a trusted partner. Contact us today to find your perfect heating solution!

Visual Guide

Related Products

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- Double Plate Heating Press Mold for Lab

People Also Ask

- What are the two types of casting machines? Hot-Chamber vs. Cold-Chamber Die Casting

- What is the theory and practice of RF sputtering? Master Thin-Film Deposition for Insulating Materials

- How much does a plastic waste pyrolysis plant cost? From $50K to $20M+

- What role does a magnetic stirrer play in the formulation of Palladium/Graphene slurry for electrode fabrication?

- What is meant by co-pyrolysis? Unlock Synergistic Benefits from Mixed Feedstocks

- What is the role of a laboratory constant temperature drying oven in anaerobic digestion? Precision TS Analysis

- What are the major components of biomass? Unlocking the Building Blocks of Renewable Energy

- What is the definition of sintering? Master Thermal Manufacturing for High-Density Solids