To be precise, tube furnaces typically feature configurations with one, two, or three heating zones, though models with up to five zones are available for highly specialized applications. The maximum achievable temperature for these furnaces commonly extends up to 1800°C, with standard models available in ranges like 1200°C, 1400°C, and 1600°C to suit different material processing needs.

The choice of a tube furnace isn't just about hitting a maximum temperature. The critical decision lies in selecting the right number of heating zones, which directly determines your level of control over the temperature profile and uniformity along the tube's length.

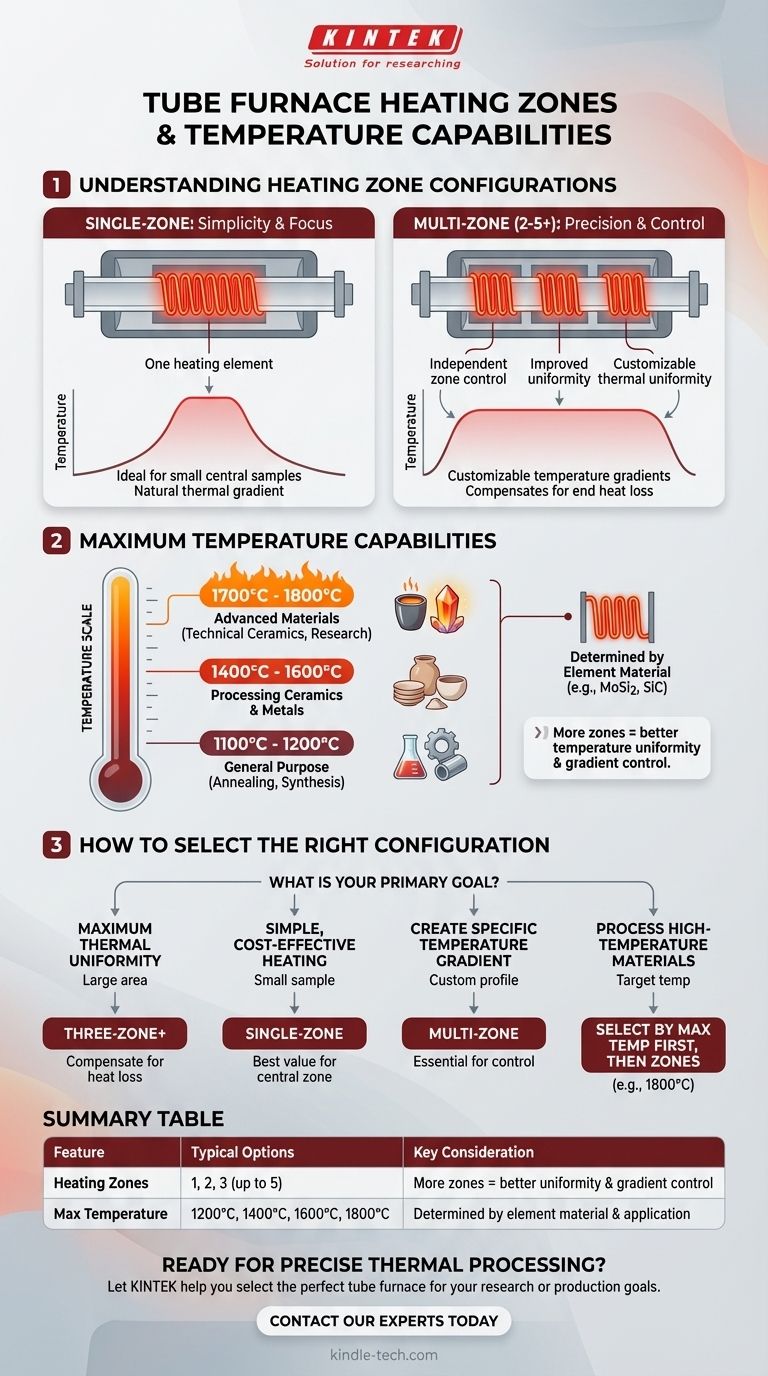

Understanding Heating Zone Configurations

The number of heating zones is the most significant factor in a tube furnace's ability to create a specific thermal environment. Each zone is independently controlled, allowing for precise temperature management.

The Single-Zone Furnace: Simplicity and Focus

A single-zone furnace has one heating element that creates a hot zone in the central portion of the tube. The temperature naturally drops off towards the ends of the tube, creating a thermal gradient.

This design is ideal for heating small samples placed directly in the center, where temperature uniformity is highest. For improved uniformity in a compact format, they can be paired with water-cooled end caps to sharpen the transition from hot to cold.

The Multi-Zone Furnace: Precision and Control

Furnaces with two, three, or more zones offer granular control over the temperature profile along the length of the tube. Each zone can be set to a different temperature.

This capability is crucial for two primary goals. First, it can compensate for heat loss at the ends of the tube, creating a much larger and more uniform hot zone. Second, it allows for the intentional creation of specific temperature gradients for processes like crystal growth or chemical vapor deposition.

Maximum Temperature Capabilities

The required operating temperature is dictated entirely by the material you are processing. Furnace manufacturers offer models tailored to common material science thresholds.

Common Temperature Tiers

Tube furnaces are typically categorized by their maximum sustainable temperature. Common tiers include:

- 1100°C - 1200°C: Suitable for many general-purpose heat treatments, annealing, and synthesis applications.

- 1400°C - 1600°C: Required for processing a wider range of ceramics and metals.

- 1700°C - 1800°C: Reserved for advanced technical ceramics and specialized high-temperature materials research.

Heating Element Materials

The maximum temperature is determined by the material of the heating elements. Molybdenum disilicide (MoSi2) or silicon carbide (SiC) elements are often used to reach temperatures up to 1800°C, while more common metallic elements serve the lower temperature ranges.

Understanding the Trade-offs: Single vs. Multi-Zone

Choosing the right configuration requires balancing performance needs with practical constraints.

Cost and Complexity

A single-zone furnace is inherently simpler, making it more cost-effective and easier to operate. As the number of zones increases, so do the cost and the complexity of the control system.

Thermal Uniformity

If your goal is to heat a long sample or multiple samples to the exact same temperature, a multi-zone furnace is superior. By setting the end zones to a slightly higher temperature, you can counteract natural heat loss and achieve excellent thermal uniformity across a significant length of the tube.

Gradient Control

A single-zone furnace can only produce one uncontrolled thermal gradient. A multi-zone furnace is the only choice for creating custom, stable, and repeatable temperature gradients, which is a requirement for many advanced materials synthesis and testing procedures.

How to Select the Right Configuration

Your specific application dictates the ideal furnace. Use your primary goal as the guiding principle for your selection.

- If your primary focus is maximum thermal uniformity over a large area: A three-zone (or more) furnace is the correct choice to compensate for end-zone heat loss.

- If your primary focus is simple, cost-effective heating of a small sample: A single-zone furnace offers the best value and simplicity for placing samples in the uniform central hot zone.

- If your primary focus is creating a specific temperature gradient: You must use a multi-zone furnace to achieve the necessary profile control.

- If your primary focus is processing high-temperature materials: First, select a model rated for your target temperature (e.g., 1800°C), and then decide on the zone configuration based on your uniformity requirements.

Ultimately, choosing the right furnace configuration begins with a clear definition of your thermal processing objective.

Summary Table:

| Feature | Typical Options | Key Consideration |

|---|---|---|

| Heating Zones | 1, 2, 3 (up to 5 for specialized use) | More zones = better temperature uniformity & gradient control |

| Max Temperature | 1200°C, 1400°C, 1600°C, 1800°C | Determined by heating element material & application requirements |

Ready to achieve precise thermal processing? Let KINTEK help you select the perfect tube furnace. We specialize in lab equipment and consumables, offering expert guidance to match the right heating zone configuration and temperature capability to your specific research or production goals. Contact our experts today for a personalized solution!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What are the primary functions of a high-temperature tube furnace for iridium-based inverse opals? Expert Annealing Guide

- What is the difference between muffle furnace and tubular furnace? A Guide to Choosing the Right Lab Furnace

- What is the primary role of a high-temperature tube furnace in CVD for CNTs? Master Precision Growth and Uniformity

- What is the function of a tube furnace? Achieve Precise High-Temperature Processing in a Controlled Atmosphere

- What are the advantages of using a Monel alloy tubular reactor? Ensure High Purity in Graphene Fluorination

- How does a precision tube furnace ensure the accuracy of wettability test results? Achieve Reliable Brazing Data

- How does the temperature control of a tube furnace affect the quality of graphene? Master the Optimal Thermal Window

- What is the significance of using a tube furnace with vacuum-sealed quartz tubes? Master Ceramic Synthesis