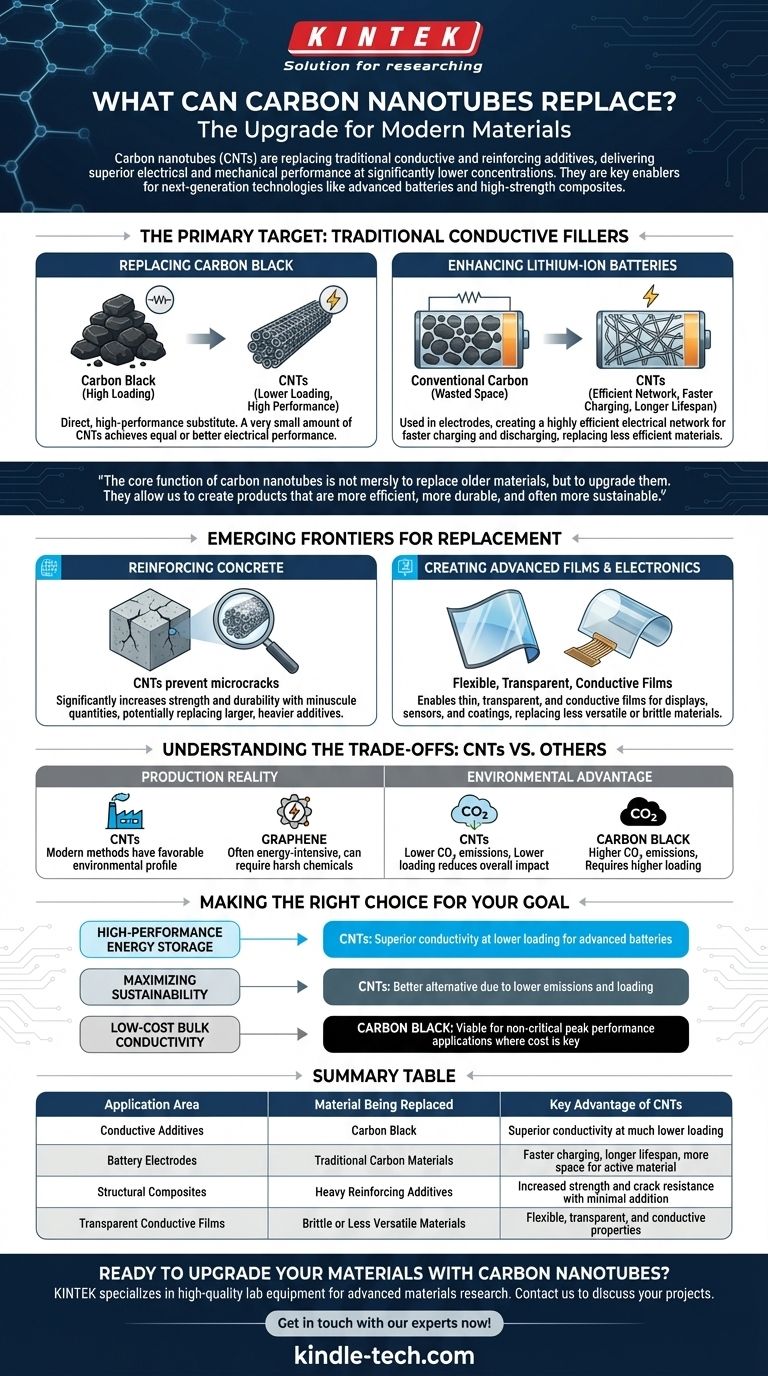

In modern material science, carbon nanotubes are positioned to replace traditional conductive and reinforcing additives, most notably carbon black. Their primary value lies in delivering superior electrical and mechanical performance at significantly lower concentrations, making them a key enabler for next-generation technologies like advanced batteries and high-strength composites.

The core function of carbon nanotubes is not merely to replace older materials, but to upgrade them. They allow us to create products that are more efficient, more durable, and often more sustainable by replacing less effective fillers like carbon black.

The Primary Target: Traditional Conductive Fillers

The most immediate and commercially significant application for carbon nanotubes (CNTs) is as a replacement for conventional carbon additives. These older materials often require high concentrations, which can compromise other properties of the host material.

Replacing Carbon Black

Carbon black has long been the industry standard for adding electrical conductivity to materials like plastics and battery electrodes.

CNTs are a direct, high-performance substitute. Due to their incredible aspect ratio and conductivity, a very small amount of CNTs can achieve the same or better electrical performance than a much larger amount of carbon black.

Enhancing Lithium-Ion Batteries

This advantage is most critical in lithium-ion batteries. CNTs are used as a conductive additive in battery electrodes, creating a highly efficient electrical network.

This network allows for faster charging and discharging and improves the battery's lifespan. They replace less efficient carbon materials that would otherwise take up valuable space that could be used for active energy storage material.

Emerging Frontiers for Replacement

Beyond their established role in batteries, CNTs are being actively explored as a reinforcing agent in structural materials and advanced electronics.

Reinforcing Concrete

Even in minuscule quantities, CNTs can significantly increase the strength and durability of concrete.

By integrating into the cement matrix, they help prevent the propagation of microcracks, potentially replacing the need for larger, heavier reinforcing additives and extending the material's service life.

Creating Advanced Films and Electronics

CNTs enable the creation of thin, transparent, and conductive films.

These films are being developed for applications like flexible electronic displays, sensors, and advanced coatings, replacing less versatile or more brittle materials used today.

Understanding the Trade-offs: CNTs vs. Other Advanced Materials

To fully grasp their value, it's essential to compare CNTs not only to traditional materials but also to other advanced carbon forms like graphene.

The Production Reality

While both materials have exceptional properties, the manufacturing process is a key differentiator. Graphene production can be energy-intensive, often requiring harsh chemicals and significant water usage.

In contrast, modern CNT manufacturing methods generally have a more favorable environmental profile, particularly regarding CO2 emissions per kilogram produced.

The Environmental Advantage

Compared to carbon black, the benefits are clear. CNT production typically results in lower CO2 emissions.

Furthermore, because you need far less of the material to achieve the desired effect (a concept known as lower loading), the overall environmental impact on the final product is further reduced. This efficiency is central to their role in green technologies.

Making the Right Choice for Your Goal

Selecting the right additive depends entirely on the technical and sustainability goals of your project.

- If your primary focus is high-performance energy storage: Carbon nanotubes are the superior choice to replace carbon black, offering better conductivity at lower loading for advanced batteries.

- If your primary focus is maximizing sustainability: CNTs often present a better alternative to both carbon black (due to lower emissions and loading) and current graphene production (due to lower energy and chemical intensity).

- If your primary focus is low-cost bulk conductivity: Traditional carbon black may remain a viable option for applications where peak performance is not a critical requirement and cost is the main driver.

Ultimately, carbon nanotubes empower engineers to move beyond simple replacement and toward genuine material enhancement.

Summary Table:

| Application Area | Material Being Replaced | Key Advantage of CNTs |

|---|---|---|

| Conductive Additives | Carbon Black | Superior conductivity at much lower loading |

| Battery Electrodes | Traditional Carbon Materials | Faster charging, longer lifespan, more space for active material |

| Structural Composites | Heavy Reinforcing Additives | Increased strength and crack resistance with minimal addition |

| Transparent Conductive Films | Brittle or Less Versatile Materials | Flexible, transparent, and conductive properties |

Ready to upgrade your materials with carbon nanotubes?

At KINTEK, we specialize in providing high-quality lab equipment and consumables to support your research and development in advanced materials. Whether you're developing next-generation batteries, high-strength composites, or innovative electronics, our products are designed to meet the precise needs of your laboratory.

Contact us today to discuss how our solutions can help you achieve superior performance and sustainability in your projects. Get in touch with our experts now!

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Bomb Type Probe for Steelmaking Production Process

- Large Vertical Graphite Vacuum Graphitization Furnace

- Evaporation Crucible for Organic Matter

People Also Ask

- What is the porosity of an RVC glassy carbon sheet? Understanding the Critical Difference Between PPI and Porosity

- What are the typical physical specifications for glassy carbon sheets? Unlock Superior Performance for Your Lab

- What are the fundamental characteristics of glassy carbon? Discover its Unique Synergy of Properties

- What is the ideal operating environment for a glassy carbon sheet? Ensure Optimal Performance and Longevity

- What is the applicable potential range for an RVC glassy carbon sheet? Master Your Electrochemical Analysis