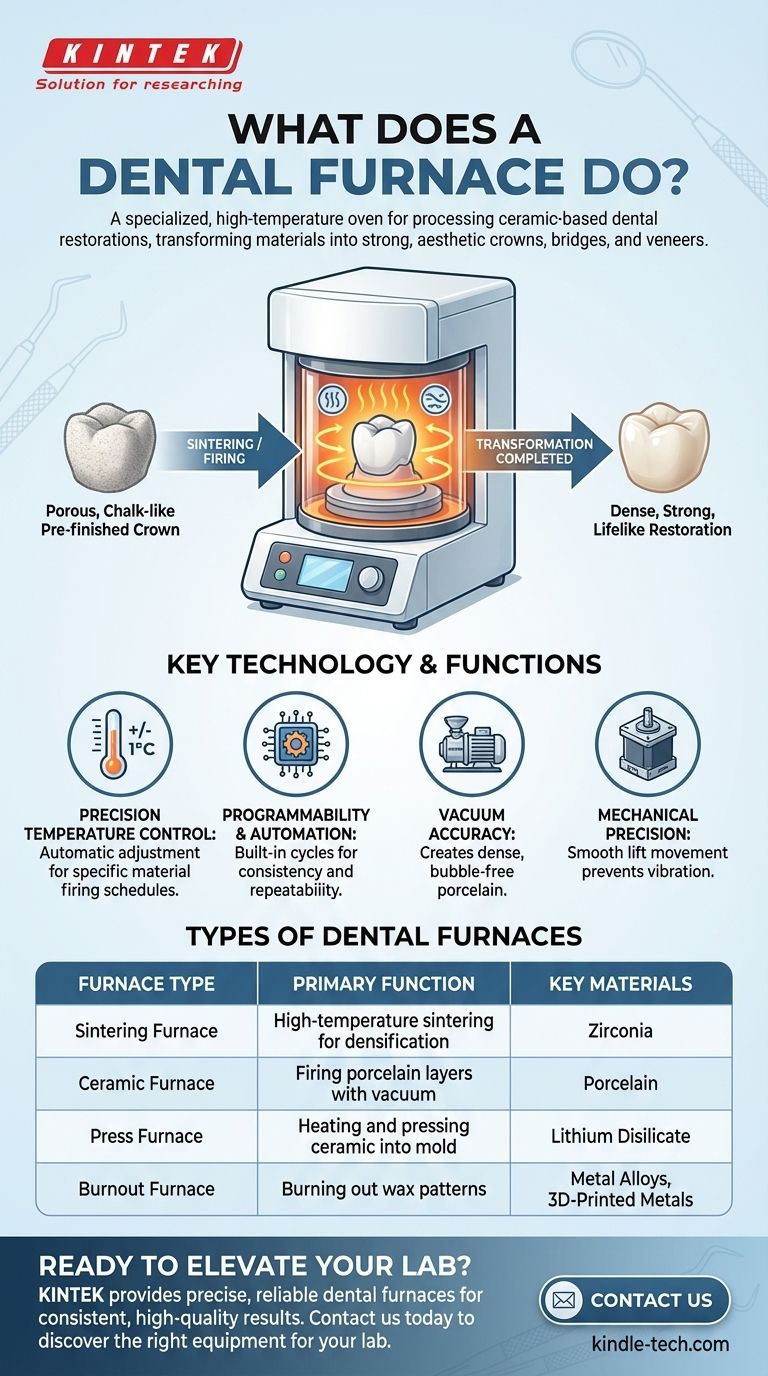

At its core, a dental furnace is a specialized, high-temperature oven used in a dental laboratory to process and finalize ceramic-based dental restorations. These devices execute highly precise heating cycles to transform materials like zirconia or porcelain into strong, durable, and aesthetically pleasing crowns, bridges, and veneers.

A dental furnace does more than simply heat materials; it executes highly precise, programmed temperature and vacuum cycles to transform milled ceramic restorations from a porous, chalk-like state into their final, dense, and lifelike form.

The Transformation: Why Heat Is Critical

The journey of a modern dental restoration, such as a crown, involves multiple stages. The final and most critical stage often happens inside a furnace, where the material undergoes a fundamental structural change.

From Porous to Permanent

When a zirconia crown is first milled, it is in an enlarged, chalk-like, and porous state. It is not yet strong enough to function in a patient's mouth.

The process of sintering inside a furnace heats this pre-finished crown to extremely high temperatures (often above 1200°C). This causes the ceramic particles to fuse, eliminating porosity, shrinking the restoration to its precise final size, and achieving its full, permanent hardness.

Achieving Aesthetic Perfection

For other restorations, the furnace is used for firing and glazing. Technicians apply layers of porcelain to a core structure and then fire it in the furnace to create a strong bond and a natural-looking layered appearance.

A final glaze firing creates a smooth, stain-resistant, and shiny surface that mimics the luster of a natural tooth.

Types of Dental Furnaces and Their Functions

The term "dental furnace" is a broad category. Different processes require different types of furnaces, each optimized for a specific task.

Sintering Furnaces

These are the high-temperature workhorses designed specifically for processing zirconia restorations. Their primary job is to reach the extreme temperatures needed to sinter zirconia to its final density and strength.

Ceramic and Press Furnaces

Often available as combination units, these furnaces are used for firing layers of porcelain and for pressing ceramic materials.

A ceramic furnace uses vacuum technology during firing to remove air from between porcelain particles, preventing bubbles and ensuring a dense, strong final layer.

A press furnace adds a mechanical pressing mechanism to the heating process. It's used for materials like lithium disilicate, where the heated ceramic is pressed into a mold to form the restoration.

Burnout Furnaces

Also known as dewaxing furnaces, these are used in the "lost-wax" technique for casting metal frameworks. They heat a mold to burn out the wax pattern inside, leaving a cavity for molten metal to be cast into. They are also used for heat-treating 3D-printed metal restorations.

Understanding the Key Technology

Modern dental furnaces are precision instruments. Their key features are not just for convenience; they are critical for achieving predictable, high-quality results.

Precision Temperature Control

The most crucial feature is automatic temperature adjustment with extreme accuracy, often within +/- 1°C. Different ceramic materials have very specific firing schedules, and any deviation can result in a failed restoration.

Programmability and Automation

Furnaces come with dozens of built-in, user-programmable cycles. This allows labs to save specific programs for different materials, ensuring consistency and repeatability for every case. Features like a USB port allow for easy program updates and service.

Vacuum Accuracy

For porcelain work, the ability to control the vacuum level is essential. Pulling a precise vacuum at the right time in the firing cycle is what creates dense, bubble-free porcelain that is both strong and beautiful.

Mechanical Precision

Advanced features like a precision stepper motor ensure the furnace lift moves smoothly and without vibration. This prevents any disturbance to the delicate porcelain powder before it has been fired.

Common Pitfalls and Considerations

While highly automated, dental furnaces require expertise to operate correctly. Understanding their limitations is key to avoiding costly errors.

Material-Specific Programs Are Not Interchangeable

The most common mistake is using the wrong program for a given material. Sintering zirconia at a temperature meant for firing porcelain will have no effect, while firing porcelain at a zirconia-sintering temperature will completely destroy it. Each material has a unique and mandatory temperature protocol.

The Critical Need for Calibration

A furnace is only as good as its temperature accuracy. Over time, thermocouples (temperature sensors) can drift. Regular calibration using standardized kits is essential to ensure the temperature displayed is the actual temperature inside the chamber, preventing under-fired or over-fired restorations.

Contamination in the Chamber

Using a single furnace for different types of materials without proper cleaning can lead to contamination. For example, residue from a metal-ceramic case can discolor a highly esthetic all-ceramic restoration in the next cycle. Many high-end labs dedicate specific furnaces to specific materials.

Making the Right Choice for Your Goal

The right furnace process is dictated entirely by the material and the desired final outcome of the restoration.

- If your primary focus is high-strength monolithic restorations (e.g., full-zirconia crowns): You need a dedicated sintering furnace capable of reaching and holding the very high temperatures required for full densification.

- If your primary focus is highly aesthetic, layered restorations (e.g., porcelain-fused-to-zirconia): You need a ceramic furnace with precise vacuum control to fire the porcelain layers without porosity.

- If your primary focus is pressable ceramics (e.g., lithium disilicate): You need a specialized press furnace that combines accurate heating with a mechanical plunger to press the material.

Ultimately, mastering the function of the dental furnace is essential for any laboratory focused on producing consistent, durable, and lifelike restorations.

Summary Table:

| Furnace Type | Primary Function | Key Materials |

|---|---|---|

| Sintering Furnace | High-temperature sintering to densify zirconia | Zirconia |

| Ceramic Furnace | Firing porcelain layers with vacuum control | Porcelain |

| Press Furnace | Heating and pressing ceramic into a mold | Lithium Disilicate |

| Burnout Furnace | Burning out wax patterns for casting | Metal Alloys, 3D-Printed Metals |

Ready to elevate your lab's capabilities?

KINTEK specializes in providing the precise, reliable lab equipment dental technicians trust. Whether you are sintering zirconia for maximum strength or firing porcelain for perfect aesthetics, the right furnace is critical for consistent, high-quality results.

Our range of dental furnaces is designed to meet the specific needs of modern laboratories, ensuring your restorations are durable, lifelike, and produced efficiently.

Contact us today via our contact form to discuss your laboratory's needs and discover how KINTEK can support your success with the right equipment.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the firing of porcelain in dentistry? The Lab Process for Strong, Life-like Crowns & Veneers

- Can a broken porcelain tooth be repaired? A Guide to Durable Dental Solutions

- What is the temperature of zirconia? Mastering the Sintering Cycle for Maximum Strength

- What is the primary function of a dental sintering furnace? Transform Zirconia into Durable Crowns & Bridges

- Are ceramic teeth expensive? Investing in Natural-Looking, Durable Dental Restorations

- What is a burnout furnace used for? Achieve Flawless Castings with Precision Thermal Processing

- Can high fusing porcelain be repaired without distortion? Yes, with the right low-fusing materials and techniques.

- Do porcelain crowns look natural? Achieve a Seamless, Lifelike Smile with Modern Dentistry