In essence, a dental oven is not merely an oven but a high-precision furnace engineered specifically for the dental laboratory. Its primary function is to execute controlled heating and cooling cycles that transform raw dental materials, like zirconia or ceramic, into strong, durable, and aesthetically pleasing dental prosthetics such as crowns, bridges, and veneers.

The core purpose of a dental oven is to perform thermal processing—a critical step that gives dental restorations their final strength, fit, and natural appearance. It is the bridge between a digitally designed restoration and a clinically viable product.

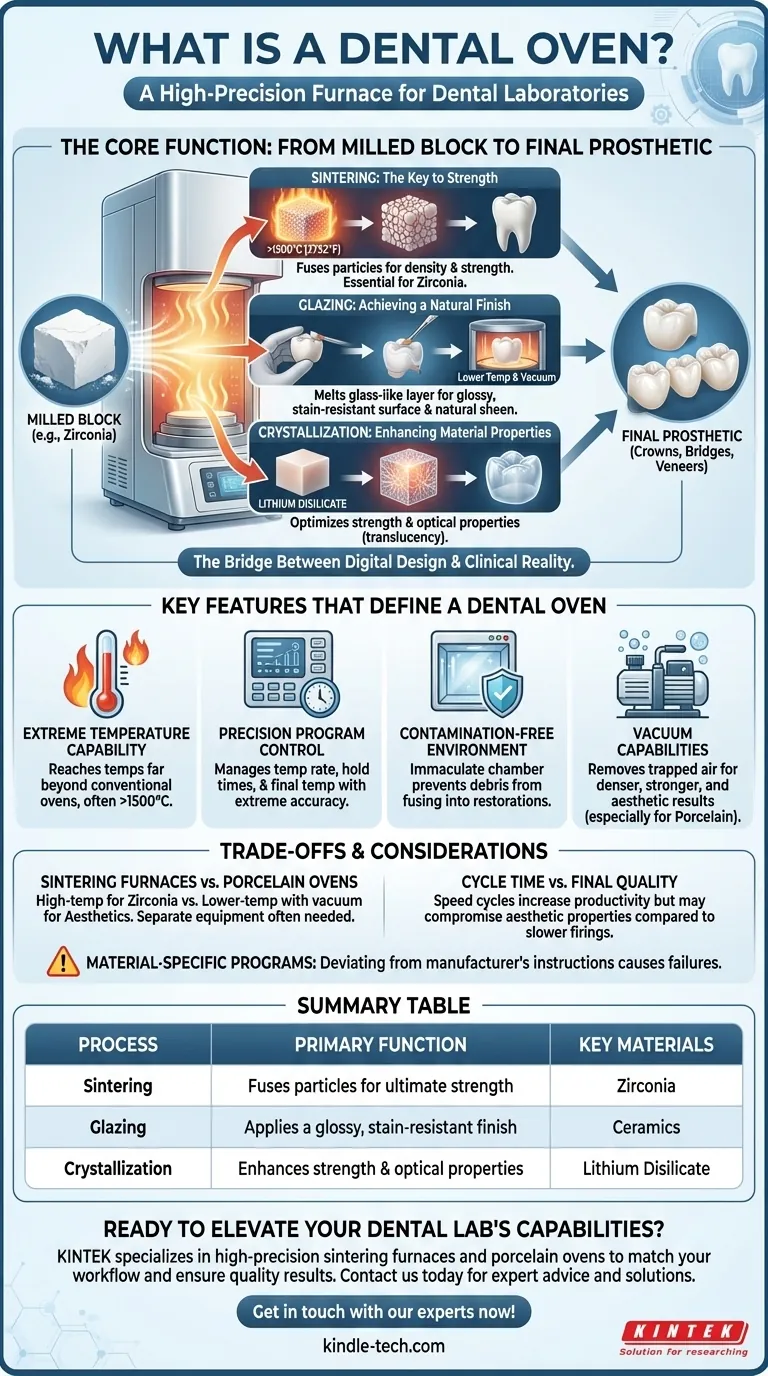

The Core Function: From Milled Block to Final Prosthetic

A dental restoration, such as a crown, often begins as a soft, chalk-like block of material. The dental oven is responsible for the crucial transformation that makes it suitable for use in a patient's mouth through several key processes.

Sintering: The Key to Strength

Sintering is the most common and critical process, particularly for materials like zirconia. This involves heating the milled restoration to extremely high temperatures, just below its melting point.

This intense heat causes the individual particles of the material to fuse, compacting the structure and dramatically increasing its density and strength. Without sintering, a zirconia crown would be weak and brittle.

Glazing: Achieving a Natural Finish

After a restoration is sintered and colored, a final glaze is often applied. The oven is used for a lower-temperature firing cycle that melts this thin, glass-like layer over the surface.

This glazing process seals the prosthetic, gives it a smooth, stain-resistant surface, and creates the natural, glossy sheen seen on real teeth.

Crystallization: Enhancing Material Properties

Certain advanced ceramics, like lithium disilicate, require a crystallization firing cycle. This specific heat treatment changes the material's internal crystalline structure.

This process optimizes both the strength and the optical properties (like translucency) of the final restoration, ensuring it is both durable and lifelike.

Key Features That Define a Dental Oven

A standard kitchen oven cannot perform these tasks. Dental ovens are distinguished by several highly specialized features that are essential for predictable, high-quality results.

Extreme Temperature Capability

Dental ovens are true furnaces, capable of reaching temperatures far beyond conventional ovens. Sintering zirconia, for example, often requires temperatures exceeding 1500°C (2732°F).

Precision Program Control

The quality of the final prosthetic depends entirely on the accuracy of the heating and cooling cycle. Dental ovens feature programmable controls that manage the rate of temperature change, hold times, and final temperature with extreme precision. An incorrect cycle can easily crack or warp the restoration.

Contamination-Free Environment

The heating chamber must be immaculately clean. Any debris or contaminants can become fused into the restoration during firing, causing discoloration or structural weak points. The materials used in the chamber itself are designed to be stable and non-reactive at high temperatures.

Vacuum Capabilities

Many ovens designed for porcelain work (like Porcelain-Fused-to-Metal crowns) are equipped with a vacuum pump. Pulling a vacuum during the firing cycle removes air trapped within the layers of porcelain, resulting in a much denser, stronger, and more aesthetic restoration free of bubbles.

Understanding the Trade-offs and Considerations

Choosing and operating a dental oven involves understanding the specific needs of the materials and the desired outcomes.

Sintering Furnaces vs. Porcelain Ovens

Labs often use different ovens for different purposes. A high-temperature sintering furnace is built for the long, extremely hot cycles required for zirconia. A porcelain oven operates at lower temperatures but requires precise vacuum control for aesthetic layering. Using one for the other's purpose is generally not possible.

Cycle Time vs. Final Quality

Many modern ovens offer "speed" or "fast" firing cycles to increase lab productivity. While efficient, these rapid cycles can sometimes compromise the final aesthetic properties, such as translucency, compared to a longer, slower firing schedule. The choice often depends on balancing case turnaround time with the desired quality.

Material-Specific Programs

You cannot use a generic program for all materials. Each manufacturer of zirconia, ceramic, or glaze provides a specific, validated firing schedule. Deviating from these instructions is a primary cause of restoration failure, leading to remakes that cost the lab time and money.

Matching the Oven to the Lab's Needs

The right equipment depends entirely on the services the dental lab offers.

- If your primary focus is high-strength zirconia crowns and bridges: A dedicated high-temperature sintering furnace capable of precise, multi-stage programs is non-negotiable.

- If your primary focus is aesthetic porcelain veneers and PFM work: A programmable porcelain oven with robust vacuum capabilities is essential for achieving bubble-free, lifelike restorations.

- If you are a full-service lab handling all material types: You will almost certainly require multiple specialized ovens to manage different workflows efficiently without risking cross-contamination.

Ultimately, the dental oven is the final gatekeeper of quality, transforming a milled shape into a functional and beautiful dental restoration.

Summary Table:

| Process | Primary Function | Key Materials |

|---|---|---|

| Sintering | Fuses particles for ultimate strength | Zirconia |

| Glazing | Applies a glossy, stain-resistant finish | Ceramics |

| Crystallization | Enhances strength & optical properties | Lithium Disilicate |

Ready to elevate your dental lab's capabilities?

Choosing the right dental oven is critical for producing strong, aesthetically perfect crowns, bridges, and veneers. KINTEK specializes in high-precision lab equipment, including sintering furnaces and porcelain ovens, designed to meet the specific demands of dental laboratories.

We can help you select the perfect equipment to match your workflow, ensuring predictable, high-quality results for every restoration. Contact us today to discuss your lab's needs and discover how our expertise can enhance your productivity and final product quality.

Get in touch with our experts now!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is sintering dental materials? The Key to Durable, High-Strength Dental Restorations

- What is the difference between zirconia and ceramic? A Guide to Choosing the Right Dental Crown

- What is the firing temperature for dental ceramics? Mastering the Critical Cycle for Strong, Aesthetic Restorations

- What is the difference between composite and ceramic restoration? Choosing the Right Material for Your Smile

- What is the sintering temperature of zirconia ceramic? Mastering the 1400°C-1600°C Thermal Profile

- What is the primary function of a dental sintering furnace? Transform Zirconia into Durable Crowns & Bridges

- At what temperature does zirconium oxide sinter? A Guide to Achieving Maximum Density and Strength

- What temperature is porcelain fired at? A Guide to Precise Dental Firing Cycles