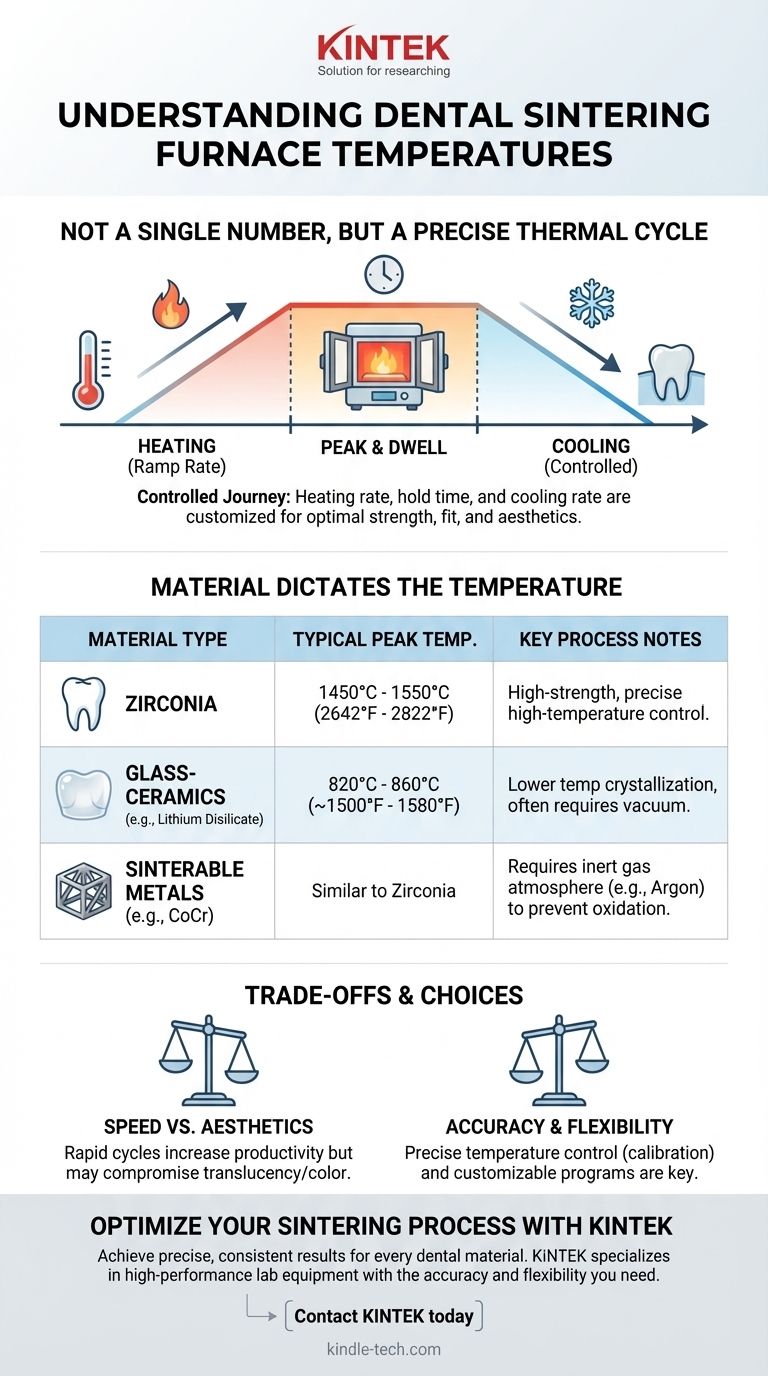

There is no single temperature for a dental sintering furnace; instead, it operates within a range, following a precise, multi-stage program. The final sintering temperature is dictated entirely by the material being processed, with high-strength zirconia typically requiring a peak temperature between 1450°C and 1550°C (2642°F to 2822°F).

The critical insight is that a dental furnace doesn't just "heat up" to one temperature. It executes a carefully controlled thermal cycle—including specific heating rates, hold times, and cooling rates—that is customized for the exact dental material to achieve the desired strength, fit, and aesthetic properties.

Why Temperature is a Cycle, Not a Single Number

A common misconception is viewing the furnace's job as simply reaching a target temperature. In reality, the entire heating and cooling journey is what determines the success of the dental restoration. This journey is managed by a configurable program.

The Role of the Sintering Program

Modern dental furnaces use multi-stage programs to control the process. Each stage, or segment, defines a specific action, such as how fast to heat up, how long to hold a temperature, and how slowly to cool down.

The Heating Rate (Ramp Rate)

This is the speed at which the furnace temperature increases, measured in degrees per minute. A ramp rate that is too fast can introduce thermal stress into the material, potentially causing cracks or an inaccurate fit in the final restoration.

Peak Temperature and Dwell Time

This is the specific target temperature required by the material manufacturer. The furnace "dwells" or holds at this peak temperature for a set period to allow the material particles to fuse together, achieving full density and strength. For zirconia, this is typically around 1500°C.

Controlled Cooling

The cooling phase is just as critical as the heating phase. Cooling too rapidly can induce thermal shock, making the restoration brittle. A slow, controlled cooling rate ensures a stable and durable final product.

How Material Dictates the Temperature

The chemical composition of the dental material is the primary factor determining the entire sintering program. Using the wrong program for a given material will lead to a complete failure.

Zirconia (The High-Temperature Standard)

Zirconium dioxide is the most common material processed in a high-temperature sintering furnace. It requires peak temperatures between 1450°C and 1550°C to achieve its final high-strength, translucent state.

Glass-Ceramics (e.g., Lithium Disilicate)

These materials are processed in what are often called "porcelain" or "all-ceramic" furnaces. They do not sinter at high temperatures but go through a crystallization process at much lower temperatures, typically around 820°C to 860°C. These furnaces almost always require a vacuum function.

Sinterable Metals (e.g., CoCr)

Some labs sinter metals like Cobalt-Chrome. This is a specialized process that also requires very high temperatures, often similar to zirconia, but must be done in an oxygen-free environment using an inert gas like argon to prevent oxidation.

Understanding the Trade-offs

Choosing a furnace and a program involves balancing competing factors. Understanding these trade-offs is key to achieving consistent, high-quality results.

Speed vs. Aesthetics

Many modern furnaces offer "speed" or "fast" sintering cycles that can dramatically reduce processing time. While effective for productivity, these rapid cycles can sometimes result in lower translucency or less accurate color matching compared to slower, conventional cycles.

Temperature Accuracy and Calibration

The furnace's ability to accurately hit and maintain the target temperature is paramount. A deviation of even a few degrees can compromise the restoration's properties. Regular calibration is essential to ensure the furnace is performing as expected.

Program Flexibility

While preset programs are convenient, the ability to customize every segment of the thermal cycle provides greater control. This allows a skilled technician to fine-tune programs to optimize results for specific shades or complex cases, as referenced by the multi-segment programmers in modern units.

Making the Right Choice for Your Goal

The ideal furnace and temperature program depends entirely on the materials you work with and your clinical or business objectives.

- If your primary focus is high-strength zirconia: You need a furnace capable of consistently reaching and holding temperatures up to 1550°C with exceptional accuracy.

- If your primary focus is aesthetic glass-ceramics: Your critical requirement is precise control and vacuum capability at lower temperatures (around 850°C).

- If you run a versatile, multi-material lab: You need a furnace with a wide operational range and a flexible, user-friendly programming interface to manage different material profiles efficiently.

Ultimately, mastering the sintering process is about precisely controlling the entire temperature journey, not just reaching a single peak.

Summary Table:

| Material Type | Typical Peak Sintering Temperature | Key Process Notes |

|---|---|---|

| Zirconia | 1450°C - 1550°C (2642°F - 2822°F) | High-strength, requires precise high-temperature control. |

| Glass-Ceramics (e.g., Lithium Disilicate) | 820°C - 860°C (~1500°F - 1580°F) | Lower temperature crystallization, often requires a vacuum. |

| Sinterable Metals (e.g., CoCr) | Similar to Zirconia | Requires an inert gas atmosphere to prevent oxidation. |

Achieve precise, consistent results for every dental material in your lab. The right sintering furnace is critical for the strength, fit, and aesthetics of your restorations. KINTEK specializes in high-performance lab equipment, including dental furnaces with the accuracy and program flexibility your laboratory needs. Let our experts help you select the ideal furnace for your specific materials and workflow. Contact KINTEK today to optimize your sintering process.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag