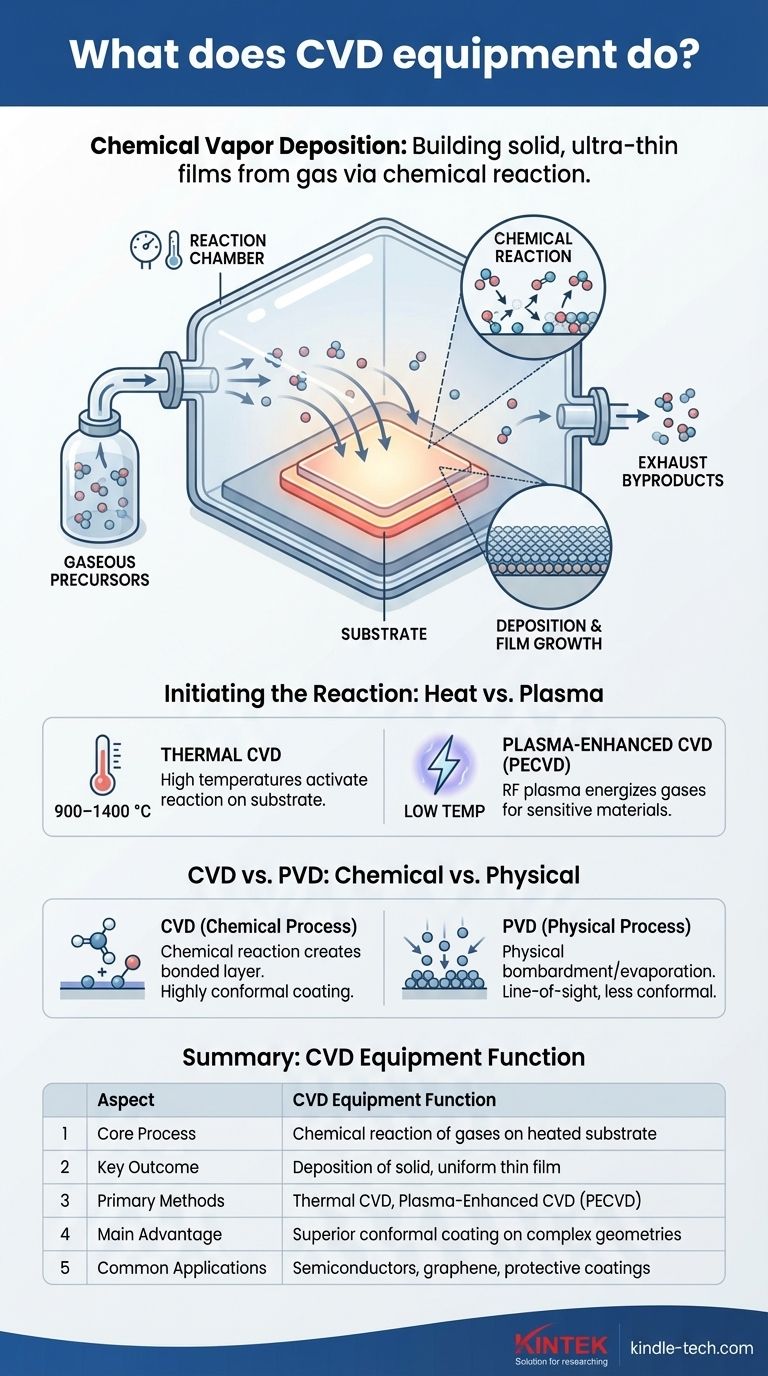

In short, Chemical Vapor Deposition (CVD) equipment is a system that builds a solid, ultra-thin film of material on a surface by using a chemical reaction from a gas. It introduces specific reactive gases, known as precursors, into a controlled chamber. These gases then react or decompose on a heated target object (the substrate), depositing a new, high-purity layer atom by atom.

The core function of CVD equipment is not to simply coat a surface, but to create a precisely controlled chemical reaction in a gaseous state. This reaction's solid byproduct forms a high-performance, uniform film that becomes an integral part of the final object.

The Core Principle: Building Solids from Gases

To understand what CVD equipment does, it's best to break the process down into its fundamental stages. The entire operation is a carefully orchestrated sequence inside a highly controlled environment.

The Starting Materials: Gaseous Precursors

The raw materials for the film are not solid chunks or liquids but are volatile gases called precursors.

These gases contain the specific atoms (like carbon for graphene or silicon for semiconductors) needed to create the final film. They are mixed with carrier gases and injected into the system.

The Environment: The Reaction Chamber

The entire process takes place inside a sealed reaction chamber.

This chamber allows for the precise control of critical variables like temperature, pressure, and the flow rate of gases, ensuring the chemical reaction happens exactly as intended.

The Foundation: The Substrate

The object being coated is called the substrate. This could be a silicon wafer, a metal foil, or another component.

The substrate is heated to a specific temperature and serves as the surface where the new film will form. In many cases, the substrate's surface also acts as a catalyst, initiating and facilitating the chemical reaction.

The Main Event: The Chemical Reaction

This is the "Chemical" in CVD. As the precursor gases flow over the hot substrate, the energy causes them to react or decompose.

This is a fundamental chemical change where gas molecules break apart and recombine to form a new, solid material.

The Result: Deposition and Film Growth

The solid product of this chemical reaction is deposited onto the substrate's surface, forming a thin, solid film.

This process builds the film layer by layer, resulting in an exceptionally uniform and high-quality coating. The film can be either crystalline (with an ordered atomic structure, like graphene) or amorphous (disordered).

The Cleanup: Exhausting Byproducts

The chemical reaction also creates gaseous byproducts that are not part of the film.

This waste gas is continuously removed from the chamber via a gas flow or vacuum system to prevent contamination and maintain the purity of the deposited layer.

Initiating the Reaction: Heat vs. Plasma

The energy needed to drive the chemical reaction is a critical factor and a key differentiator in CVD systems.

Thermal CVD

This is the most common method, relying on high temperatures (often 900–1400 °C) to provide the necessary activation energy for the precursor gases to react on the substrate.

Plasma-Enhanced CVD (PECVD)

For substrates that cannot withstand high temperatures, plasma is used to energize the precursor gases instead.

An RF (radio frequency) plasma dissociates the gases into reactive ions and radicals at a much lower temperature, allowing for deposition on sensitive materials like plastics.

Understanding the Trade-offs: Chemical vs. Physical Deposition

It's crucial to distinguish CVD from its counterpart, Physical Vapor Deposition (PVD), to understand its unique function.

The Core Distinction

CVD is a chemical process. It creates a film of a new material through a chemical reaction on the substrate's surface. This results in a strong, chemically bonded layer.

PVD is a physical process. It involves physically bombarding, evaporating, or sublimating a solid source material in a vacuum and having it condense on the substrate. No fundamental chemical reaction occurs.

Why Choose CVD?

CVD is often chosen when film quality and uniformity are paramount. Because the precursor is a gas, it can flow into and coat complex, non-line-of-sight geometries with a highly conformal layer, something PVD struggles with. The resulting films are often denser and have superior adhesion.

Making the Right Choice for Your Goal

The type of CVD equipment and process you use depends entirely on the material you are depositing and the substrate you are coating.

- If your primary focus is high-purity, crystalline films on heat-resistant substrates: Traditional Thermal CVD is the established standard for applications in semiconductors or advanced materials like graphene.

- If your primary focus is coating temperature-sensitive materials like polymers or certain electronics: Plasma-Enhanced CVD (PECVD) is the necessary choice, as it achieves high-quality deposition without requiring damagingly high temperatures.

- If your primary focus is creating a very dense, adherent, and uniform coating on a complex shape: CVD is generally superior to line-of-sight physical deposition methods.

Ultimately, CVD equipment provides a powerful and precise method for engineering materials at the atomic level, enabling the creation of advanced films that are fundamental to modern technology.

Summary Table:

| Aspect | CVD Equipment Function |

|---|---|

| Core Process | Chemical reaction of gases on a heated substrate |

| Key Outcome | Deposition of a solid, uniform thin film |

| Primary Methods | Thermal CVD, Plasma-Enhanced CVD (PECVD) |

| Main Advantage | Superior conformal coating on complex geometries |

| Common Applications | Semiconductors, graphene, protective coatings |

Ready to engineer materials at the atomic level? KINTEK specializes in advanced CVD equipment and consumables for laboratories. Whether you need high-purity thermal systems for semiconductor research or low-temperature PECVD for sensitive substrates, our solutions deliver precise, uniform films for your most critical applications. Contact our experts today to discuss how our CVD technology can accelerate your R&D and production.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating