In short, plasma is generated in Plasma-Enhanced Chemical Vapor Deposition (PECVD) by applying electrical energy to a precursor gas. This energy, typically in the form of a radio frequency (RF) field, is not used to heat the entire chamber but to specifically energize free electrons. These high-energy electrons collide with gas molecules, knocking more electrons loose and creating a cascade of ions and reactive neutral species, resulting in a self-sustaining, low-temperature plasma known as a glow discharge.

The central concept of PECVD is the substitution of brute-force thermal energy with targeted electrical energy. Instead of heating a substrate to extreme temperatures to break chemical bonds, PECVD uses a plasma to create a highly reactive chemical environment at a much lower overall temperature.

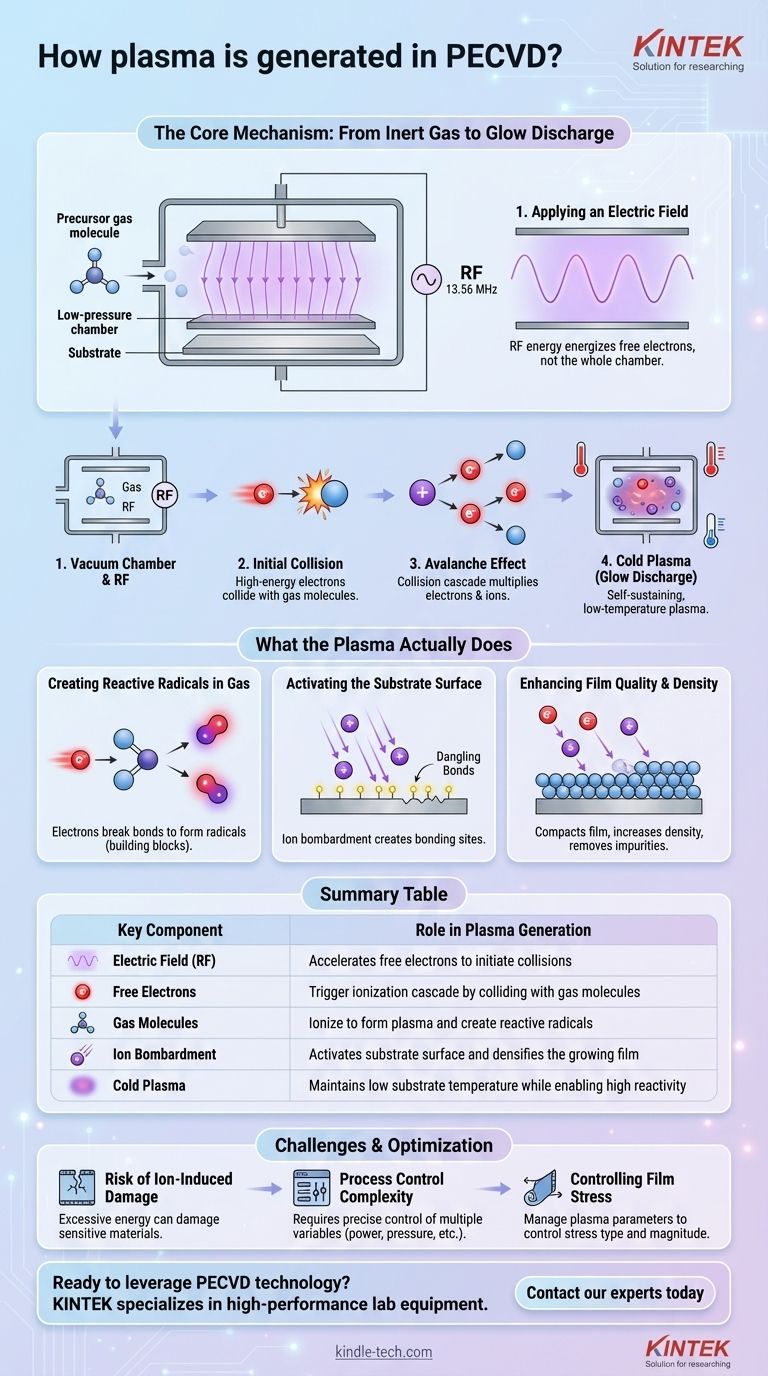

The Core Mechanism: From Inert Gas to Glow Discharge

To understand the value of PECVD, you must first understand how this reactive environment is created. The process is a controlled chain reaction that transforms a stable gas into a potent tool for film deposition.

Applying an Electric Field

The process begins inside a vacuum chamber containing the substrate. A precursor gas mixture is introduced at low pressure. An electric field, most commonly a radio frequency (RF) signal at 13.56 MHz, is applied between two electrodes within the chamber.

The Initial Collision

Even in a vacuum, a few free electrons always exist. The electric field accelerates these electrons, giving them significant kinetic energy. When one of these high-energy electrons collides with a neutral gas molecule, it has enough force to knock another electron off that molecule.

The Avalanche Effect

This collision leaves behind a positively charged ion and two free electrons. These two electrons are then accelerated by the RF field, striking and ionizing other gas molecules. This collision cascade or "avalanche" rapidly multiplies the number of free electrons and ions, igniting and sustaining the plasma.

The Nature of a "Cold Plasma"

Crucially, the plasma in PECVD is a "cold plasma" or glow discharge. This means the light, fast-moving electrons are extremely hot (energetically), while the much heavier ions and neutral gas molecules remain near ambient temperature. This energy imbalance is the key to PECVD's low-temperature advantage.

What the Plasma Actually Does

Generating the plasma is only the first step. Its true function lies in how its components—electrons, ions, and radicals—interact with the gas and the substrate to build a film.

Creating Reactive Radicals in the Gas

The most important role of the energetic electrons is to collide with stable precursor gas molecules. These collisions have enough energy to break chemical bonds, creating highly reactive neutral species known as radicals. These radicals are the primary building blocks for the deposited film.

Activating the Substrate Surface

The positively charged ions created in the plasma are accelerated by the electric field toward the substrate. This ion bombardment is not just random; it serves to activate the surface by creating atomic-scale bonding sites, often called "dangling bonds." This makes the surface chemically receptive to the radicals.

Enhancing Film Quality and Density

The same ion bombardment helps to physically compact the growing film, increasing its density. It can also function as a micro-etching process, selectively sputtering away weakly bonded atoms or undesirable byproducts. This results in a purer, more robust film with stronger adhesion.

Common Pitfalls and Considerations

While powerful, the use of plasma is not without its challenges. Understanding these trade-offs is critical for process control and achieving desired film properties.

The Risk of Ion-Induced Damage

While ion bombardment is beneficial for densification, excessive energy can be destructive. High-energy ion strikes can create defects in the growing film or even damage the underlying substrate, which is a major concern when working with sensitive materials like polymers or advanced semiconductors.

The Complexity of Process Control

PECVD introduces more process variables compared to simple thermal CVD. Plasma power, frequency, gas pressure, and chamber geometry all interact in complex ways. Achieving consistent, repeatable results requires precise control and a deep understanding of how these parameters influence the plasma chemistry.

Controlling Film Stress

The energetic nature of plasma deposition inherently creates stress within the deposited film. While this can sometimes be beneficial, uncontrolled stress can cause the film to crack or delaminate. Managing plasma parameters is essential to control the type (compressive or tensile) and magnitude of this stress.

Making the Right Choice for Your Goal

The plasma in a PECVD system is not just an on/off switch; it is a highly tunable instrument. By adjusting its parameters, you can prioritize different aspects of the deposition process to meet specific goals.

- If your primary focus is depositing on heat-sensitive substrates: The key is to leverage the low-temperature nature of the glow discharge, using just enough plasma power to create radicals without causing significant substrate heating.

- If your primary focus is a dense, high-quality barrier film: Moderate ion bombardment is critical. You must carefully balance plasma power and pressure to achieve densification without introducing damaging defects.

- If your primary focus is controlling film properties like stress or refractive index: The plasma chemistry is your main lever. Subtle changes in gas mixture, power, and frequency can be used to fine-tune the film's final mechanical and optical characteristics.

Ultimately, mastering plasma generation is the key to unlocking the full potential of PECVD for advanced material fabrication.

Summary Table:

| Key Component | Role in Plasma Generation |

|---|---|

| Electric Field (RF) | Accelerates free electrons to initiate collisions |

| Free Electrons | Trigger ionization cascade by colliding with gas molecules |

| Gas Molecules | Ionize to form plasma and create reactive radicals |

| Ion Bombardment | Activates substrate surface and densifies the growing film |

| Cold Plasma | Maintains low substrate temperature while enabling high reactivity |

Ready to leverage PECVD technology for your advanced material fabrication? KINTEK specializes in high-performance lab equipment and consumables for precise thin film deposition. Our PECVD systems are engineered for exceptional process control, enabling you to deposit high-quality films on even the most heat-sensitive substrates. Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and accelerate your research and development.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition