In short, DLC coating is a specialized surface treatment that creates a thin, exceptionally hard, and low-friction film on a component. Known as Diamond-Like Carbon, its primary purpose is to drastically increase wear resistance and reduce friction on surfaces, combining some of the best properties of both natural diamond and graphite.

The core function of DLC is to solve problems of friction and wear. It acts as a microscopic layer of armor that is both harder than steel and more slick than Teflon, significantly extending the life and improving the efficiency of the parts it protects.

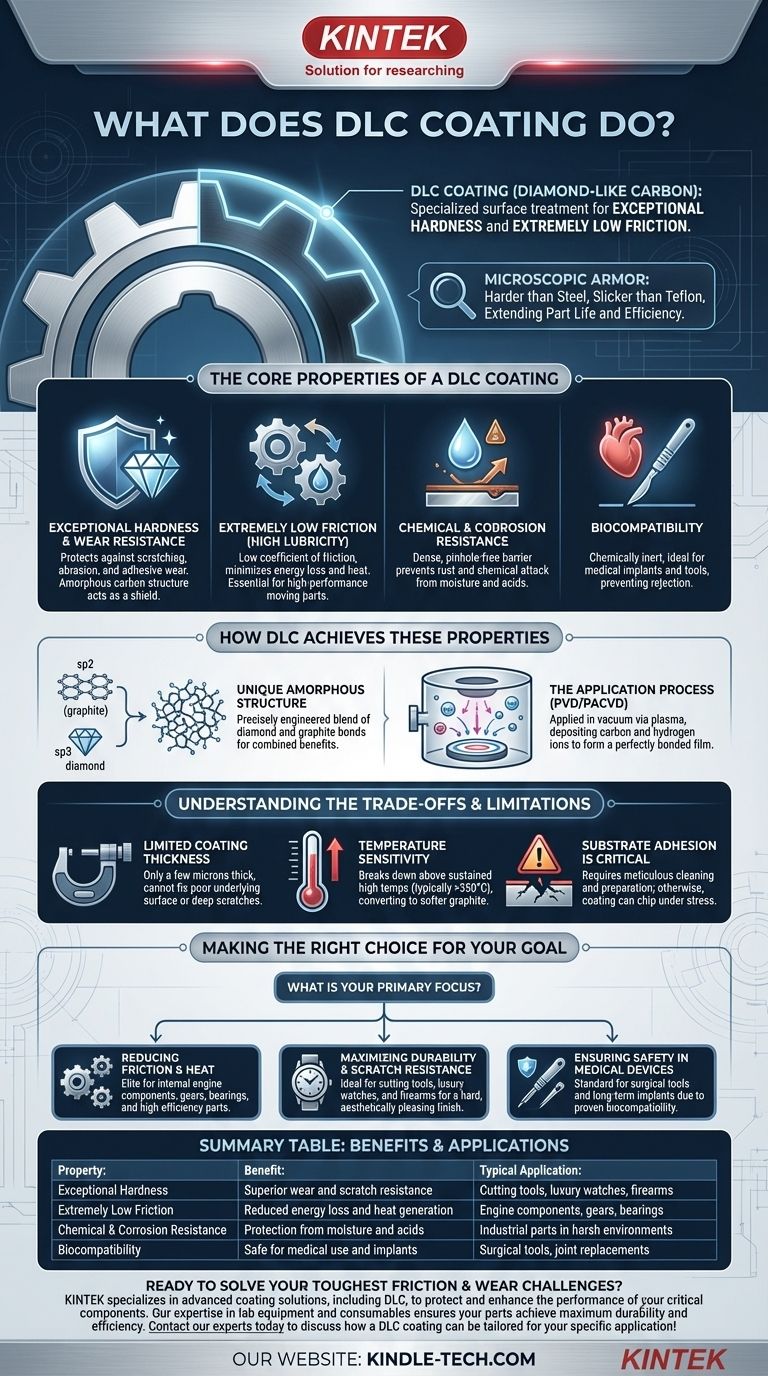

The Core Properties of a DLC Coating

To understand what DLC does, we need to look at its unique combination of benefits. These properties do not typically exist together in a single material, which is what makes DLC so effective for demanding applications.

Exceptional Hardness and Wear Resistance

The "diamond-like" name is earned from its extreme hardness. This amorphous carbon structure protects a component's surface from scratching, abrasion, and adhesive wear, acting as a shield against physical damage.

Extremely Low Friction (High Lubricity)

DLC coatings have a coefficient of friction that is remarkably low, often compared to that of Teflon. This inherent lubricity means parts can move against each other with minimal energy loss and heat generation, which is critical for high-performance moving components.

Chemical and Corrosion Resistance

The dense, pinhole-free structure of a DLC film creates an effective barrier. It isolates the underlying material (the substrate) from moisture, acids, and other corrosive agents, preventing rust and chemical attack.

Biocompatibility

DLC is chemically inert and does not react with biological tissue. This makes it an ideal coating for medical implants, such as joint replacements and surgical tools, where it prevents rejection and reduces wear inside the body.

How DLC Achieves These Properties

The remarkable capabilities of DLC stem from its unique atomic structure and the advanced process used to apply it.

A Unique Amorphous Structure

Unlike natural diamond (pure sp3 bonds) or graphite (pure sp2 bonds), DLC is amorphous, meaning its atoms lack long-range order. It's a precisely engineered blend of both bond types, allowing it to capture the hardness of diamond and the low-friction, graphitic nature of graphite in one material.

The Application Process (PVD/PACVD)

The coating is applied in a vacuum chamber using a process like Plasma-Assisted Chemical Vapor Deposition (PACVD). As the reference material hints, a hydrocarbon gas is introduced and energized into a plasma. This breaks the gas down, allowing carbon and hydrogen ions to deposit onto the target component atom by atom, forming a hard, dense, and perfectly bonded film.

Understanding the Trade-offs and Limitations

While powerful, DLC is a specialized solution with specific constraints that are important to understand.

Limited Coating Thickness

DLC is a surface film, not a bulk material. It is typically applied in thicknesses of only a few microns (a few thousandths of a millimeter). It cannot correct for deep scratches or poor underlying surface quality.

Temperature Sensitivity

Standard DLC coatings can begin to break down and lose their beneficial properties at sustained high temperatures (typically above 350°C). The diamond-like structure can begin to convert to softer graphite, negating its hardness.

Substrate Adhesion is Critical

The performance of the coating is entirely dependent on its bond to the material underneath. The substrate must be meticulously cleaned and prepared before coating to ensure perfect adhesion, otherwise, the film can chip or flake off under stress.

Making the Right Choice for Your Goal

Selecting DLC is a decision based on solving a specific engineering challenge.

- If your primary focus is reducing friction and heat: DLC is an elite choice for internal engine components, gears, and bearings where efficiency and minimal energy loss are paramount.

- If your primary focus is maximizing durability and scratch resistance: It is an ideal solution for cutting tools, luxury watches, and firearms that require a hard, wear-resistant, and aesthetically pleasing finish.

- If your primary focus is ensuring safety in medical devices: Its proven biocompatibility and wear resistance make it a standard in high-performance surgical tools and long-term implants.

Ultimately, DLC is an engineering tool used to fundamentally change the performance characteristics of a surface, conquering friction and wear at a microscopic level.

Summary Table:

| Property | Benefit | Typical Application |

|---|---|---|

| Exceptional Hardness | Superior wear and scratch resistance | Cutting tools, luxury watches, firearms |

| Extremely Low Friction | Reduced energy loss and heat generation | Engine components, gears, bearings |

| Chemical & Corrosion Resistance | Protection from moisture and acids | Industrial parts in harsh environments |

| Biocompatibility | Safe for medical use and implants | Surgical tools, joint replacements |

Ready to solve your toughest friction and wear challenges? KINTEK specializes in advanced coating solutions, including DLC, to protect and enhance the performance of your critical components. Our expertise in lab equipment and consumables ensures your parts achieve maximum durability and efficiency. Contact our experts today to discuss how a DLC coating can be tailored for your specific application!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer