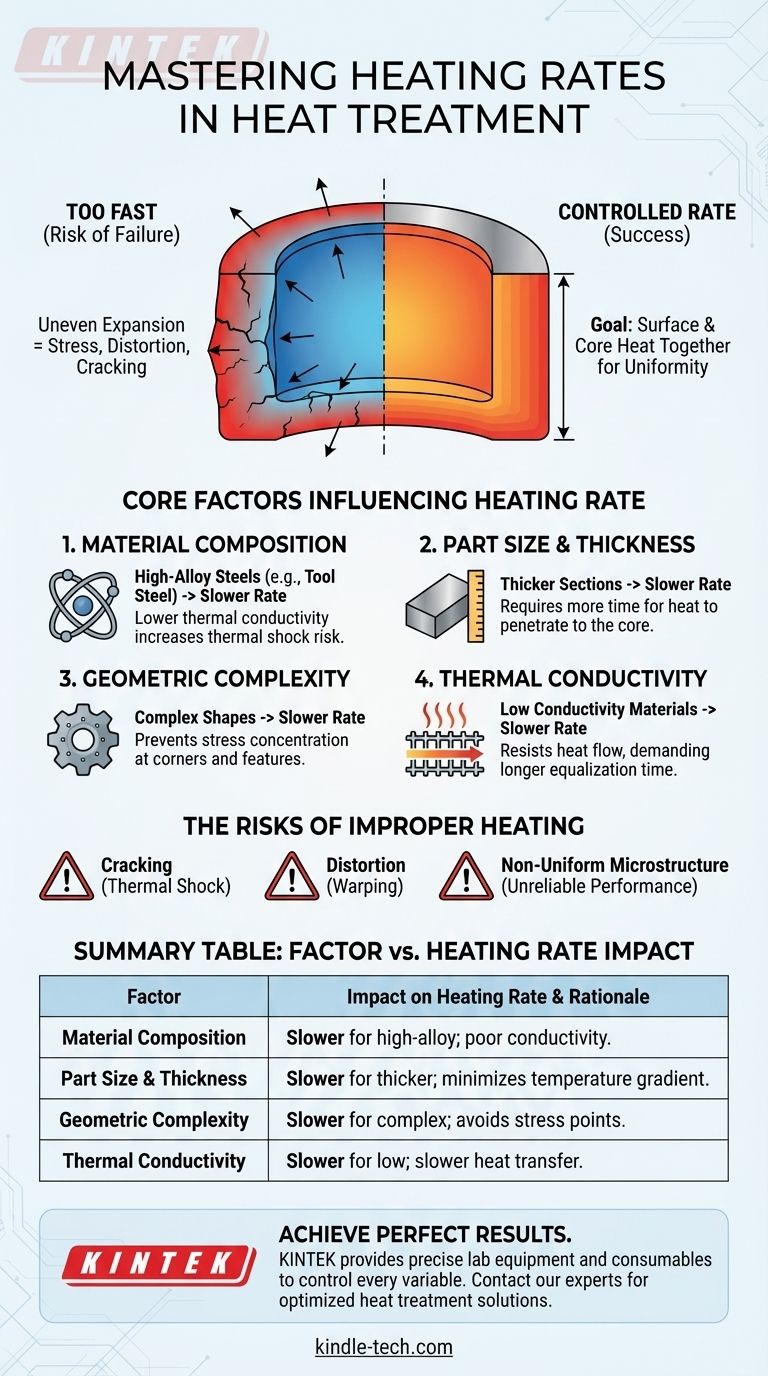

The heating rate in heat treatment is not a one-size-fits-all parameter. It is a carefully controlled variable determined by the material's composition, its ability to conduct heat, and the physical size and complexity of the part. An incorrect heating rate is one of the most common sources of failure in heat treatment, as heating too quickly can create internal stresses that lead to distortion or even catastrophic cracking.

The central goal is to heat the component at a rate that allows its core temperature to keep pace with its surface temperature. This ensures uniform thermal expansion and metallurgical transformation, which is the key to preventing internal stress, distortion, and cracking.

Core Factors Influencing Heating Rate

The correct heating rate is a balance between process efficiency and metallurgical safety. Several interconnected factors dictate the maximum safe speed at which a part can be heated.

Material Composition and Alloy Content

The type and amount of alloying elements in a metal are primary drivers. High-alloy steels, such as tool steels, contain elements like chromium, molybdenum, and tungsten, which generally reduce the material's thermal conductivity.

These materials are poor at transferring heat internally and are highly susceptible to thermal shock. They demand slow, careful heating, often with one or more pre-heating stages, to prevent cracking. Simple low-carbon steels have better thermal conductivity and can tolerate much faster heating rates.

Part Size and Cross-Sectional Thickness

This is arguably the most critical practical consideration. The larger and thicker a component is, the longer it takes for heat to penetrate from the surface to the core.

If a thick part is heated too quickly, its surface will expand significantly while its core remains cool and contracted. This differential expansion creates immense internal stress. Therefore, thick sections always require slower heating rates to minimize this temperature gradient.

Geometric Complexity

A part's shape significantly impacts how it responds to heating. Components with sharp corners, holes, or abrupt changes in thickness (e.g., a shaft with a large flange) have built-in stress concentrators.

Rapid, uneven heating will cause these features to heat and expand at different rates than the bulk of the part, المحليting in high localized stress. To prevent distortion and cracking at these points, a slow and uniform heating rate is essential.

Thermal Conductivity of the Material

This physical property ties all the other factors together. Thermal conductivity is a measure of how efficiently a material transfers heat.

Materials with high thermal conductivity, like aluminum alloys, allow heat to distribute through the part quickly and evenly. They can often be heated rapidly. Materials with low thermal conductivity, like stainless steels and high-alloy tool steels, resist heat flow and must be heated slowly to achieve thermal equilibrium.

Understanding the Trade-offs: The Risks of Improper Heating

Choosing a heating rate is about managing risk. While faster heating is more economical, the potential costs of failure are severe.

The Danger of Thermal Shock and Cracking

This is the most catastrophic failure mode. When the surface heats and expands far more rapidly than the core, it creates powerful internal tensile stresses. If these stresses exceed the material's yield strength, the part will crack. This is especially common in brittle, high-hardness materials.

Distortion and Warping

Uneven heating causes uneven expansion, which can permanently deform a part. For components that require tight dimensional tolerances, such as gears, bearings, or engine components, any warping can render them useless. Slow, uniform heating is the primary defense against distortion.

Non-Uniform Microstructure

The purpose of heat treatment is to achieve a specific, desirable crystal structure (microstructure) within the metal. If a part heats unevenly, different sections may not reach the required transformation temperature or may pass through it at different rates. This results in inconsistent hardness, strength, and toughness across the component, leading to unpredictable and unreliable performance in service.

Making the Right Choice for Your Goal

Your heating strategy must be tailored to the specific material and geometry of your component.

- If your part is large or has a thick cross-section: Prioritize a slow, uniform heating rate to allow the core temperature to equalize with the surface, minimizing internal stress.

- If you are working with high-alloy or tool steels: Use a conservative, slow heating rate, often with pre-heating stages, to prevent thermal shock and cracking due to their low thermal conductivity.

- If your part is small, simple, and made of low-carbon steel: You can often use a faster heating rate, as thermal gradients will be less severe and the risk of cracking is lower.

- If you are dealing with complex geometries or tight tolerances: Always default to a slower, more controlled heating rate to prevent distortion and stress concentration at sharp corners.

Ultimately, a controlled heating rate is the foundation of successful heat treatment, directly ensuring the structural integrity and performance of the final component.

Summary Table:

| Factor | Impact on Heating Rate | Rationale |

|---|---|---|

| Material Composition | High-alloy steels require slower rates. | Lower thermal conductivity increases risk of thermal shock. |

| Part Size & Thickness | Thicker sections require slower rates. | Minimizes temperature gradient between surface and core. |

| Geometric Complexity | Complex shapes require slower rates. | Prevents stress concentration at sharp corners and holes. |

| Thermal Conductivity | Low conductivity demands slower rates. | Heat transfers slowly, requiring more time for uniformity. |

Achieve perfect heat treatment results every time. The correct heating rate is critical to preventing costly failures like cracking and distortion. KINTEK specializes in providing the precise lab equipment and consumables your laboratory needs to control every variable. Our expertise ensures your materials achieve the desired microstructure and properties reliably.

Let us help you optimize your process. Contact our experts today to discuss your specific heat treatment challenges and discover the right solutions for your lab.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is a nitriding furnace? Achieve Superior Surface Hardening with Minimal Distortion

- What is the inside of a kiln made of? Discover the Refractory Materials That Withstand Extreme Heat

- How does a high-temperature sintering furnace transform c-LLZO green bodies into dense ceramic electrolytes? Expert Guide

- What role does a laboratory vacuum furnace play in the preparation of high-temperature molten salt experimental samples?

- Can you braze thick aluminum? Yes, with the right heat and atmosphere control for strong joints.

- What is physical Vapour deposition in crystal growth? Master Atomic-Level Thin Film Fabrication

- What core function does a high-temperature sintering furnace serve? Optimize All-Ceramic Composite Cathode Production

- What's the difference between brazing and braze welding? Mastering Joint Strength & Application