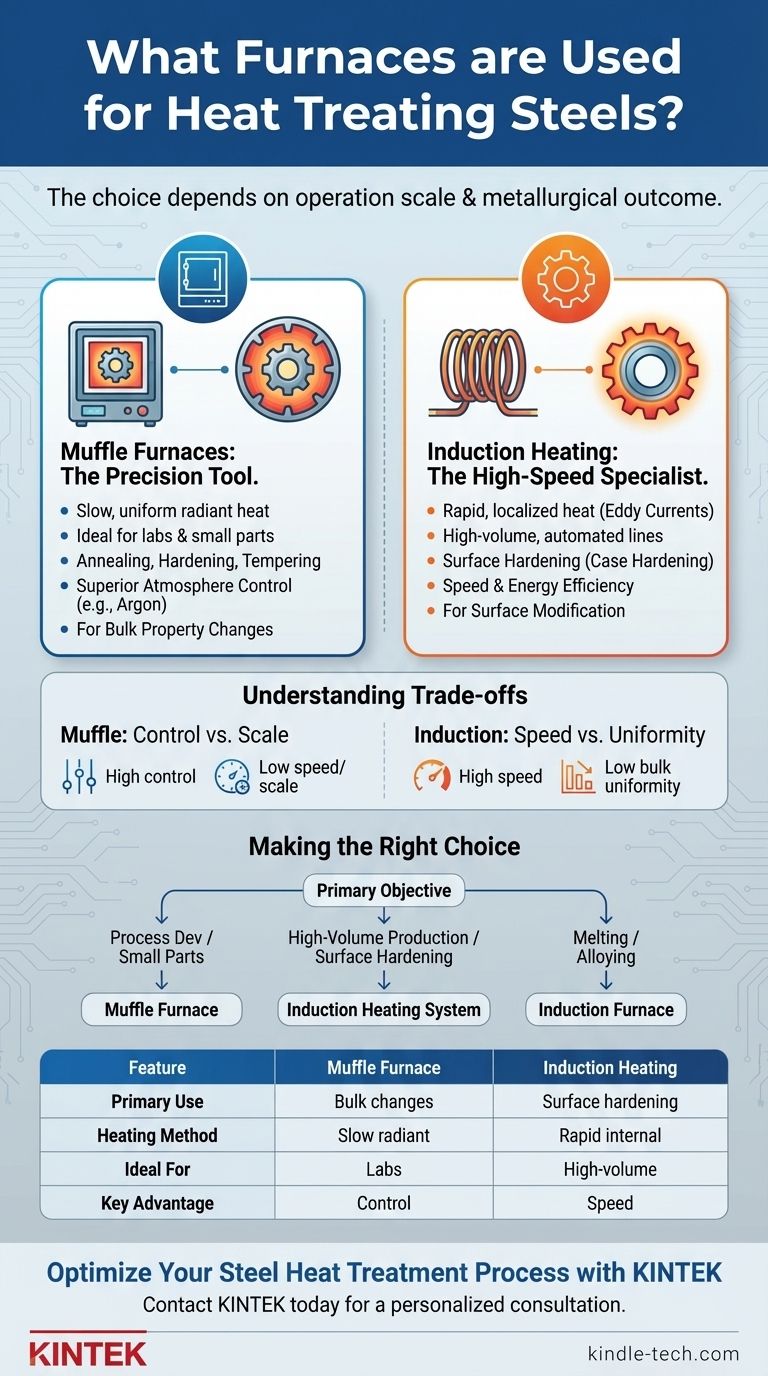

For heat treating steel, the choice of furnace depends entirely on the scale of the operation and the desired metallurgical outcome. While muffle furnaces are a common solution for achieving precise, uniform changes in smaller parts, induction heating systems are used for rapid, high-volume surface treatments. Both methods alter the steel's properties, but they do so in fundamentally different ways.

The critical distinction is not between furnace brands, but between heating methodologies. Muffle furnaces provide slow, uniform heat for bulk property changes, while induction heating offers rapid, localized heat for surface modification.

Understanding Muffle Furnaces: The Precision Tool

A muffle furnace is the go-to instrument when temperature uniformity and atmospheric control are paramount. It is a foundational piece of equipment in metallurgical labs and small-scale production.

What is a Muffle Furnace?

A muffle furnace works by heating an outer chamber, which in turn radiates heat into a separate, sealed inner chamber—the "muffle." The steel part inside the muffle is never exposed to the direct flame or heating elements.

This indirect heating method ensures an exceptionally stable and uniform temperature throughout the entire part.

Primary Applications

As noted, muffle furnaces are typically small. This makes them ideal for laboratory testing, process development, and heat-treating high-value, intricate components like tool steels or small machine parts.

They are perfectly suited for processes like annealing (softening), hardening, and tempering, where the entire cross-section of the part must achieve a specific temperature.

The Benefit of Atmosphere Control

Because the muffle is a sealed chamber, the atmosphere inside can be carefully controlled. This is critical for preventing oxidation and scaling on the steel's surface during heating. An inert gas, like argon, can be introduced to protect the part's finish and integrity.

Induction Heating: The High-Speed Specialist

While large induction furnaces are designed for melting metal, the underlying technology—induction heating—is a powerful and widely used method for specific heat-treating applications.

How Induction Heating Works

Induction heating uses a powerful, high-frequency alternating current passed through a copper coil. This creates a strong magnetic field that induces electrical currents (eddy currents) directly within the steel part itself.

These currents generate intense heat rapidly and precisely in a localized area, heating the part from the inside out without any physical contact from a heat source.

When to Use Induction

This method excels at surface hardening, also known as case hardening. By heating the surface of a steel part (like a gear tooth or a shaft bearing surface) very quickly and then quenching it, you can create a hard, wear-resistant outer layer while keeping the inner core tough and ductile.

Its speed and repeatability make it ideal for automated, high-volume production lines where thousands of identical parts need the same surface treatment.

Understanding the Trade-offs

Neither technology is universally superior. The choice involves a clear set of engineering trade-offs between control, speed, and scale.

Muffle Furnaces: Control vs. Scale

The primary strength of a muffle furnace is its process control. You get unparalleled temperature uniformity and atmosphere management.

The main limitation is speed and size. Heating cycles are slow, measured in hours, and the furnace's capacity is limited, making it inefficient for large-scale production.

Induction Heating: Speed vs. Uniformity

The undeniable advantage of induction is speed and selectivity. Heating takes seconds, not hours, and it is extremely energy-efficient because it only heats the part, not a large furnace chamber.

However, it is not well-suited for uniformly treating the entire bulk of a complex part. It excels at surface treatment and requires carefully designed coils for each specific part geometry, adding upfront cost and complexity.

Making the Right Choice for Your Goal

To select the correct technology, you must first define your primary objective.

- If your primary focus is process development or treating small, high-value parts: A muffle furnace provides the precision and uniform heating necessary for achieving specific bulk material properties.

- If your primary focus is high-volume production with a need for surface hardening: An induction heating system offers the speed, efficiency, and repeatability required for industrial-scale operations.

- If your primary focus is simply melting or alloying steel for casting: A traditional induction furnace (not just a heater) is the correct tool for its efficiency in melting metals with minimal loss.

By understanding these core differences, you can confidently select the heating technology that aligns with your specific operational needs and metallurgical goals.

Summary Table:

| Feature | Muffle Furnace | Induction Heating |

|---|---|---|

| Primary Use | Bulk property changes (annealing, tempering) | Surface hardening (case hardening) |

| Heating Method | Slow, uniform radiant heat | Rapid, localized internal heat |

| Ideal For | Labs, small-scale production, intricate parts | High-volume, automated production lines |

| Key Advantage | Superior temperature & atmosphere control | Speed, energy efficiency, and selectivity |

Optimize Your Steel Heat Treatment Process with KINTEK

Choosing the right furnace is critical to achieving the precise material properties your components require. Whether you need the uniform heating and atmospheric control of a muffle furnace for R&D and small batches, or the high-speed efficiency of an induction system for mass production, KINTEK has the expertise and equipment to meet your laboratory's unique challenges.

We specialize in providing reliable lab equipment and consumables tailored to your metallurgical goals. Let our experts help you select the perfect solution to enhance your efficiency and results.

Contact KINTEK today for a personalized consultation and discover the difference the right equipment can make.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do traditional high-temperature sintering furnaces facilitate YSZ thin films? Achieving the Gold Standard.

- What is the ashing method? A Guide to Accurate Mineral Content Analysis

- What is a microwave furnace? Unlock Faster, More Uniform Heating for Advanced Materials

- How does a high-temperature muffle furnace facilitate the control of crystalline phase transformations in TiO2?

- What role does a high-temperature muffle furnace play in BZCY72 densification? Master Precision Sintering at 1500°C

- For what purpose is a programmed temperature heat treatment furnace used when testing MPCF/Al composites? Space Testing

- What is ashing in mineral analysis? Key Steps for Accurate Elemental Analysis

- What is the construction of a muffle furnace? A Deep Dive into Its Core Systems