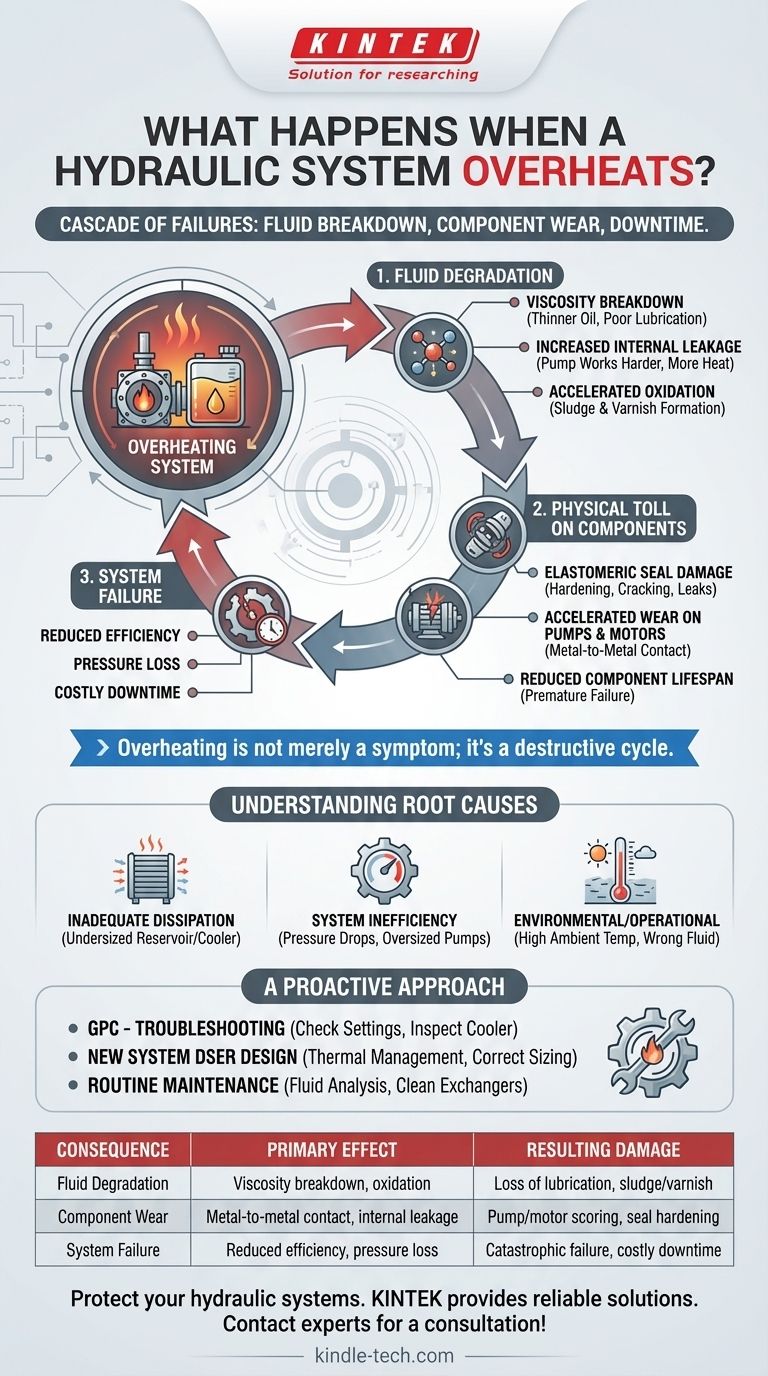

When a hydraulic system overheats, its fluid begins to chemically break down, losing its ability to lubricate and protect components. This triggers a cascade of failures, including seal degradation, accelerated metal wear, and a severe loss of system efficiency, ultimately leading to costly downtime and component destruction.

Overheating is not merely a symptom; it's a destructive cycle. Excessive heat permanently degrades the hydraulic fluid, which then fails to protect system components, generating more friction and even more heat until the system fails.

The Vicious Cycle of Heat and Degradation

The most immediate and critical consequence of overheating is its effect on the hydraulic fluid itself. Heat acts as a catalyst for a chain reaction that undermines the entire system.

Fluid Viscosity Breakdown

High temperatures cause the viscosity of hydraulic oil to drop significantly. The fluid becomes thinner and less able to maintain the critical lubricating film between moving metal parts.

This loss of viscosity is the first step toward accelerated wear, as it compromises the fluid's core function.

Increased Internal Leakage

As the oil thins, it more easily bypasses the tight clearances within pumps, motors, and valves. This phenomenon is known as internal leakage.

This leakage reduces the system's efficiency, meaning the pump must work harder (and generate more heat) to perform the same amount of work. This creates a dangerous feedback loop where heat causes leakage, and leakage creates more heat.

Accelerated Oxidation and Sludge Formation

Heat dramatically accelerates the oxidation rate of the oil. This chemical reaction creates byproducts like varnish and sludge.

Varnish deposits coat internal surfaces, causing valves to stick and reducing heat dissipation. Sludge clogs filters, strainers, and small orifices, starving components of lubrication and leading to catastrophic failure.

The Physical Toll on System Components

Once the fluid is compromised, the damage to the system's physical hardware begins to accumulate rapidly.

Elastomeric Seal Damage

Hydraulic seals, O-rings, and hoses are typically made from specific polymer compounds designed to operate within a set temperature range.

Excessive heat causes these materials to harden, become brittle, and crack. This results in fluid leaks, loss of pressure, and the introduction of contaminants into the system.

Accelerated Wear on Pumps and Motors

With the lubricating film compromised by low viscosity, metal-to-metal contact occurs inside the pump and motors.

This leads to abrasive wear, scoring of precision surfaces, and the generation of metal particles that contaminate the entire system, spreading the damage.

Reduced Component Lifespan

Every component is affected. The combination of high heat, degraded fluid, and particulate contamination drastically shortens the operational life of valves, cylinders, accumulators, and hoses.

Understanding the Root Causes

Overheating is almost always a symptom of a design flaw or operational issue. Understanding the source is key to preventing it.

Inadequate Heat Dissipation

The system cannot get rid of the heat it generates. This is often due to an undersized reservoir, which doesn't allow the fluid enough time to cool.

It can also be caused by a dirty, clogged, or undersized heat exchanger (cooler) that is no longer effective.

System Inefficiency as a Heat Source

Every time fluid flows across a pressure drop without performing useful work, the energy is converted directly into heat.

Common sources include relief valves opening frequently, flow controls causing large pressure drops, or using oversized pumps for the required function. An inefficient circuit is a heat factory.

Environmental and Operational Factors

Operating a hydraulic system in a high ambient temperature environment can overwhelm its designed cooling capacity.

Similarly, using the wrong type of hydraulic fluid or operating with fluid levels that are too low can lead to rapid overheating.

A Proactive Approach to Thermal Management

Addressing hydraulic temperature is not about fixing a single problem but about maintaining the health of the entire system.

- If you are troubleshooting an overheating system: Your first priority is to identify the source of excess heat. Check relief valve settings, inspect the cooler for blockages, and measure pressure drops across the circuit to find the inefficiency.

- If you are designing a new system: Ensure thermal management is a core consideration. Correctly size the reservoir and heat exchanger based on a thermal load calculation, and design the circuit for maximum efficiency.

- If you are performing routine maintenance: Make fluid analysis a regular practice. A check for oxidation and viscosity loss can predict an overheating problem before it causes damage. Keep heat exchangers clean and ensure fluid levels are correct.

Ultimately, maintaining the correct operating temperature is the single most important factor in ensuring the longevity and reliability of any hydraulic system.

Summary Table:

| Consequence | Primary Effect | Resulting Damage |

|---|---|---|

| Fluid Degradation | Viscosity breakdown, oxidation | Loss of lubrication, sludge/varnish formation |

| Component Wear | Metal-to-metal contact, internal leakage | Pump/motor scoring, seal hardening/cracking |

| System Failure | Reduced efficiency, pressure loss | Catastrophic failure, costly downtime |

Protect your hydraulic systems from catastrophic failure. Overheating leads to fluid breakdown, accelerated wear, and costly downtime. KINTEK specializes in lab equipment and consumables, providing reliable solutions for maintaining optimal hydraulic system performance. Ensure your laboratory's efficiency and longevity—contact our experts today for a consultation on your specific needs!

Visual Guide

Related Products

- Vacuum Cold Trap Direct Cold Trap Chiller

- Automatic Laboratory Heat Press Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Gold Electrochemical Sheet Electrode Gold Electrode

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- Why was the hydraulic press invented? To Solve the Industrial Revolution's Force Problem

- Why are high-pressure hydraulic presses necessary for UHMWPE? Mastering Zero-Flow Material Processing

- How do you prepare a sample for XRD? Achieve Accurate Phase Identification with Proper Technique

- How are moulding presses rated? A Guide to Clamping Force, Platen Size, and Key Specs

- What is the primary function of a high-tonnage uniaxial hydraulic press? Optimize High-Entropy Alloy Consolidation

- How does a laboratory hydraulic press contribute to the preparation of shaped Fischer-Tropsch Synthesis catalysts?

- What role does a laboratory hydraulic press play in constructing tri-layer composite solid-state electrolytes?

- What size sample for XRF? The Key to Accurate Elemental Analysis