The single most important safety precaution when using a standard laboratory melting point apparatus is to remain vigilant of its high-temperature surfaces to prevent serious burns. While a typical apparatus appears benign, its internal heating block can reach several hundred degrees Celsius, posing a significant and often underestimated thermal hazard. Always assume the unit is hot until you have verified it is cool to the touch.

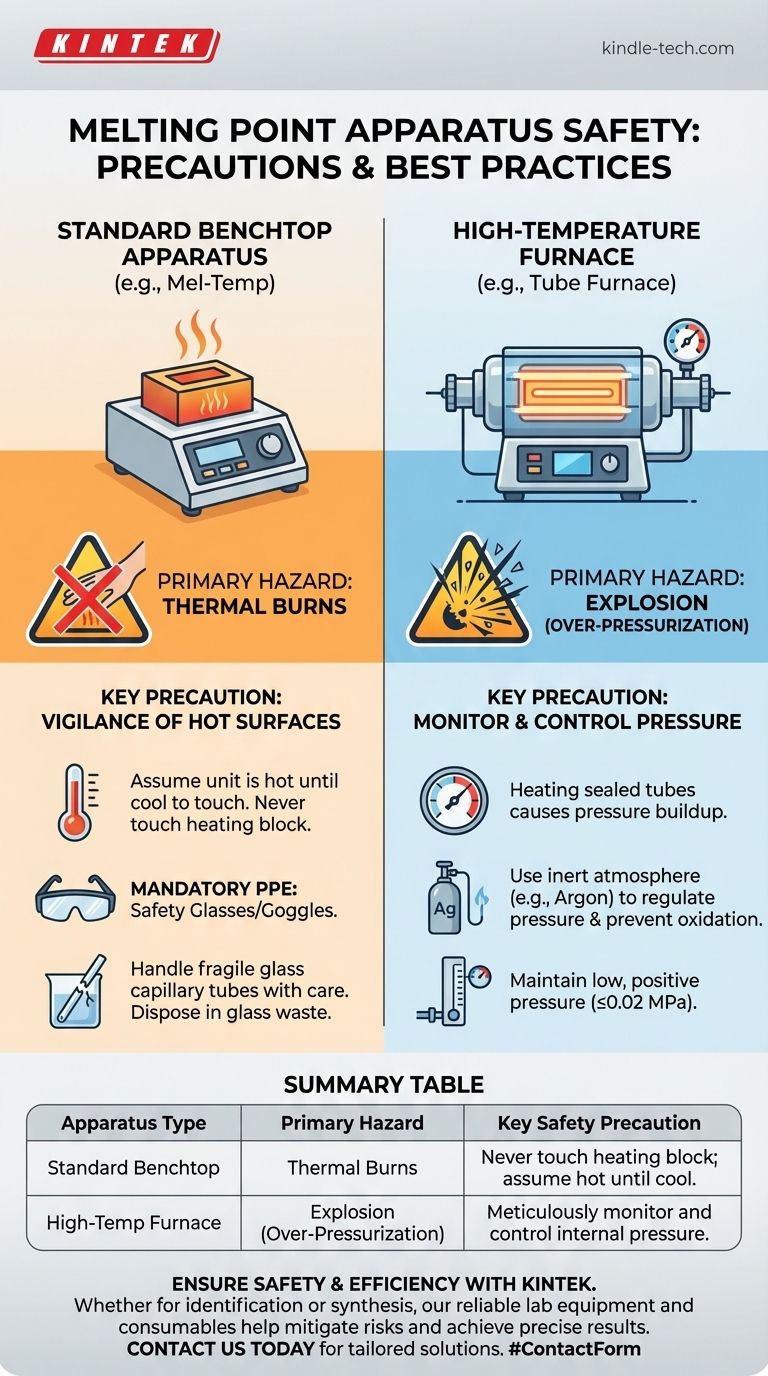

The specific safety precautions you must take depend entirely on the type of "melting point apparatus" you are using. For a standard benchtop unit, the primary risk is thermal burns. For a specialized high-temperature furnace, the primary risk is catastrophic failure from over-pressurization.

Core Safety for Standard Melting Point Apparatus

Most academic and quality control labs use a standard apparatus (like a Mel-Temp or similar device) to determine the melting point of a small chemical sample in a glass capillary tube. For this common task, the hazards are straightforward.

Preventing Thermal Burns

The core function of the apparatus is to generate heat, often well above 200°C (400°F). The heating block, sample chamber, and surrounding metal or ceramic parts retain this heat long after the device is turned off.

Never touch the heating block or sample insertion area during or after operation. Allow the apparatus to cool completely before storing it or attempting to retrieve a broken capillary tube from the chamber.

Proper Personal Protective Equipment (PPE)

At a minimum, safety glasses or goggles are mandatory. Although the sample size is small, there is a risk of the capillary tube breaking or a chemical decomposing and releasing fumes or particles.

A lab coat protects your skin and clothing, and heat-resistant gloves may be necessary if you need to handle parts of the unit while it is still warm.

Handling Glass Capillary Tubes

The capillary tubes used to hold the sample are thin, fragile glass. They can easily break when being packed with the sample or inserted into the apparatus, creating a puncture or laceration hazard.

Handle them with care and never force a tube into the apparatus. Dispose of all used and broken capillary tubes in a designated glass waste container.

Specialized High-Temperature Systems

The reference material describes a much more complex piece of equipment, likely a tube furnace used for smelting or high-temperature synthesis, not simple melting point identification. For these systems, the safety priorities shift dramatically.

Why Pressure Is the Critical Factor

This type of apparatus, which uses a sealed quartz tube, presents a significant explosion risk. Heating a sealed or partially sealed tube will cause the gas pressure inside to increase dramatically, governed by the ideal gas law.

As stated in the references, monitoring and controlling the pressure is the paramount safety concern. If the pressure exceeds the structural integrity of the quartz tube, the tube can shatter violently, sending hot projectiles and chemicals across the lab.

The Role of an Inert Atmosphere

The use of flowing argon gas serves two purposes: it displaces oxygen to prevent the sample from oxidizing or burning at high temperatures, and it helps regulate the system's pressure.

Maintaining a low, positive pressure (e.g., ≤0.02 MPa) under a slow flow prevents air from leaking in while also ensuring pressure does not build to a dangerous level.

Common Pitfall: Confusing the Apparatus

The most dangerous safety error is applying the wrong set of precautions to your equipment because of a misunderstanding of its function.

Standard Apparatus: For Identification

A standard melting point apparatus is a diagnostic tool. It uses a tiny sample to identify a compound or assess its purity. The primary hazards are localized heat and broken glass.

High-Temperature Furnace: For Synthesis or Smelting

A tube furnace is a processing tool. It is used to create new materials or fundamentally change a substance at extreme temperatures. The primary hazards are systemic and include high pressure, potential explosions, and reactions with atmospheric gases.

Matching Your Precautions to Your Equipment

Your safety actions must align with the real-world risks of the specific instrument in front of you.

- If your primary focus is using a standard benchtop melting point apparatus: Prioritize thermal safety by being mindful of hot surfaces and always wearing your safety glasses.

- If your primary focus is operating a high-temperature tube furnace: Prioritize system integrity by meticulously controlling gas flow and monitoring internal pressure to prevent a catastrophic rupture.

Understanding the function of your equipment is the foundation of working safely.

Summary Table:

| Apparatus Type | Primary Hazard | Key Safety Precaution |

|---|---|---|

| Standard Benchtop (e.g., Mel-Temp) | Thermal Burns | Never touch heating block; assume it's hot until cool. |

| High-Temperature Furnace | Explosion from Over-Pressurization | Meticulously monitor and control internal pressure. |

Ensure your lab's safety and efficiency with the right equipment from KINTEK.

Whether you require a standard melting point apparatus for identification or a high-temperature furnace for synthesis, KINTEK specializes in providing reliable lab equipment and consumables tailored to your laboratory's specific needs. Our expertise helps you mitigate risks and achieve precise, safe results.

Contact us today to discuss your requirements and let our specialists guide you to the ideal solution.

Visual Guide

Related Products

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Automatic Laboratory Heat Press Machine

- Three-dimensional electromagnetic sieving instrument

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How does an electrochemical workstation evaluate corrosion resistance of welded joints? Expert Testing Guide

- What is the significance of Electrochemical Impedance Spectroscopy (EIS)? Decode Kinetics & Stability in Catalysts

- How does a three-electrode electrochemical workstation assess TA10 titanium corrosion? Expert Testing Insights

- Why is a potentiostat or galvanostat indispensable for assessing the corrosion resistance of high-entropy alloy coatings?

- What are the core functions of a high-precision electrochemical workstation? Optimize 304L Passive Film Analysis