At its core, a diffusion furnace is a specialized high-temperature oven used to modify the properties of materials at the atomic level, most notably in semiconductor manufacturing. It creates a precisely controlled environment of extreme heat (often over 1000°C) and a specific gas atmosphere or moderate vacuum to drive chemical reactions or the movement of atoms within a substrate.

The primary purpose of a diffusion furnace isn't just to heat things up; it's to create an ultra-stable and ultra-clean environment where high thermal energy can drive specific material changes with extreme precision across many substrates at once.

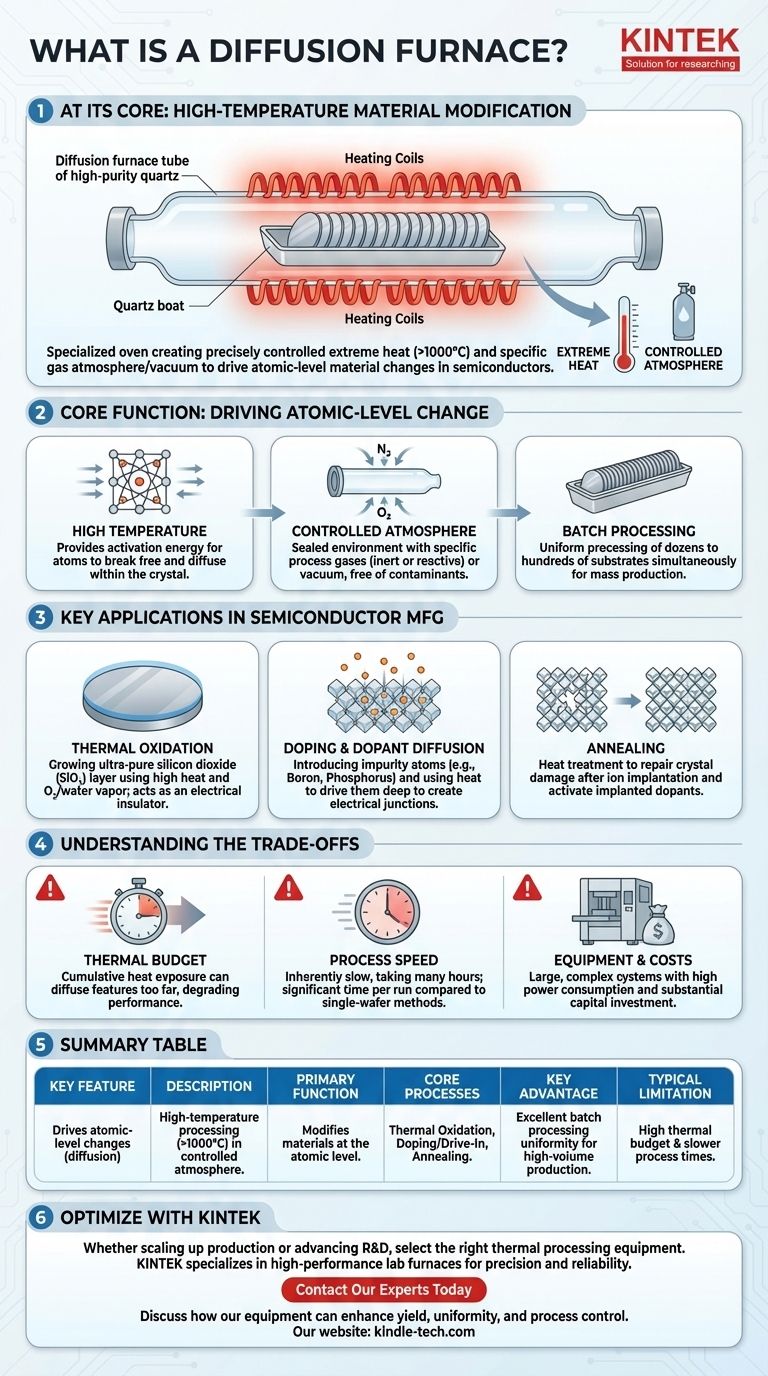

The Core Function: Driving Atomic-Level Change

A diffusion furnace is fundamentally an instrument of control. It manipulates temperature and atmosphere to enable processes that would otherwise be impossible.

The Role of High Temperature

High, sustained temperature provides the activation energy required for atoms to move or for chemical reactions to occur.

Think of the atoms in a solid crystal as being locked in place. The intense heat from the furnace gives them enough energy to break free from their fixed positions and "diffuse" or move through the crystal lattice.

The Need for a Controlled Atmosphere

This process cannot happen in open air. The furnace tube, typically made of high-purity quartz, is sealed to maintain a controlled environment free of contaminants.

This allows engineers to either pull a vacuum or, more commonly, introduce specific process gases. These might be inert gases like nitrogen to prevent unwanted reactions or reactive gases like oxygen to intentionally grow an oxide layer.

Batch Processing for Efficiency

A key characteristic of these furnaces is their size and ability to perform batch processing.

Substrates, such as silicon wafers, are loaded into a quartz "boat" which can hold dozens or even hundreds of wafers at a time. This entire boat is then inserted into the furnace, allowing for highly uniform processing across a large quantity of material, which is critical for mass production.

Key Applications in Semiconductor Manufacturing

The controlled environment of a diffusion furnace is foundational to creating the building blocks of modern electronics.

Thermal Oxidation

This is the process of growing a very thin, exceptionally pure layer of silicon dioxide (SiO₂) on the surface of a silicon wafer. This is achieved by exposing the wafers to high heat in the presence of oxygen or water vapor.

This oxide layer is an excellent electrical insulator and is one of the most critical components in a transistor.

Doping and Dopant Diffusion

Doping is the process of intentionally introducing impurity atoms (like boron or phosphorus) into the silicon crystal to precisely change its electrical conductivity.

While other methods can place dopants on the surface, the diffusion furnace provides the prolonged heat necessary to drive these dopants deep into the wafer, creating the specific electrical junctions that make transistors and diodes function.

Annealing

After processes like ion implantation (another doping method), the wafer's crystal structure can be damaged.

Annealing is a heat treatment process performed in a furnace to repair this damage and to electrically "activate" the implanted dopants, essentially healing the crystal and settling the new atoms into the lattice.

Understanding the Trade-offs

While powerful, the diffusion furnace is not without its limitations, which are a major consideration in advanced chip design.

The "Thermal Budget"

Every high-temperature step adds to a wafer's total thermal budget. This is the cumulative amount of heat it has been exposed to.

Too much heat can cause previously created structures and dopant profiles to diffuse further than intended, blurring the microscopic features of a circuit and degrading performance. Managing this budget is a constant challenge.

Process Speed

Diffusion is inherently a slow process, with furnace runs often taking many hours to complete. While batch processing improves overall throughput, the time per run is significant compared to faster, single-wafer methods like Rapid Thermal Processing (RTP).

Equipment and Operating Costs

Diffusion furnaces are large, complex systems that consume significant power and require specialized facilities. The capital investment and ongoing operational costs are substantial, making them suitable primarily for high-volume manufacturing environments.

Making the Right Choice for Your Process

The decision to use a diffusion furnace hinges on the required precision, volume, and the thermal constraints of your device.

- If your primary focus is high-volume, uniform oxide growth or creating deep dopant junctions: The diffusion furnace is the industry-standard tool, offering unmatched quality and consistency in a batch process.

- If your primary focus is creating very shallow, precisely controlled doped regions with minimal thermal impact: You may need to use alternative processes like ion implantation followed by a more targeted rapid thermal anneal (RTA).

- If your primary focus is R&D or low-volume fabrication: A large production furnace may be overkill; smaller, more flexible single-wafer processing systems might be more appropriate.

Ultimately, the diffusion furnace remains a foundational workhorse of microfabrication, valued for its ability to produce highly uniform and pure material layers at massive scale.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Function | Drives atomic-level changes (diffusion) in materials via high-temperature processing. |

| Core Processes | Thermal Oxidation, Doping/Drive-In, Annealing. |

| Key Advantage | Excellent batch processing uniformity for high-volume production. |

| Typical Limitation | High thermal budget and slower process times compared to single-wafer tools. |

Optimize your semiconductor fabrication process with KINTEK.

Whether you are scaling up production or advancing your R&D, selecting the right thermal processing equipment is critical. KINTEK specializes in high-performance lab equipment, including furnaces designed for precision and reliability.

We provide solutions tailored to the needs of semiconductor manufacturers and research laboratories. Contact our experts today to discuss how our equipment can enhance your yield, uniformity, and process control.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis